Regulatory Oversight Report for Uranium Mines and Mills in Canada: 2015

Regulatory Oversight Report for Uranium Mines and Mills in Canada: 2015 (PDF 4019 kb)

Table of contents

Section I: Operating Uranium Mines and Mills

- 2 Overview

- 3 Cigar Lake Operation

- 4 McArthur River Operation

- 5 Rabbit Lake Operation

- 6 Key Lake Operation

- 7 McClean Lake Operation

Section II: Historic (Remediating) and Decommissioned Uranium Mines and Mills

Section II-A: Historic (Remediating) Uranium Mines and Mills

Section II-B: Decommissioned Uranium Mines and Mills

- Beaverlodge

- Cluff Lake

- Rayrock

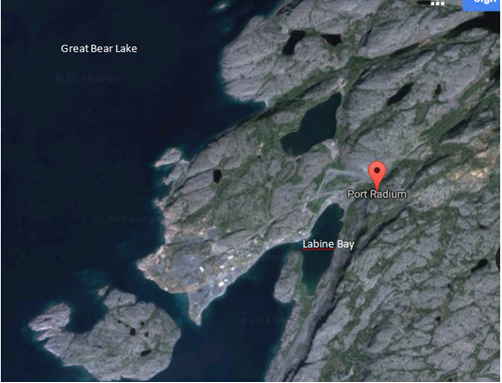

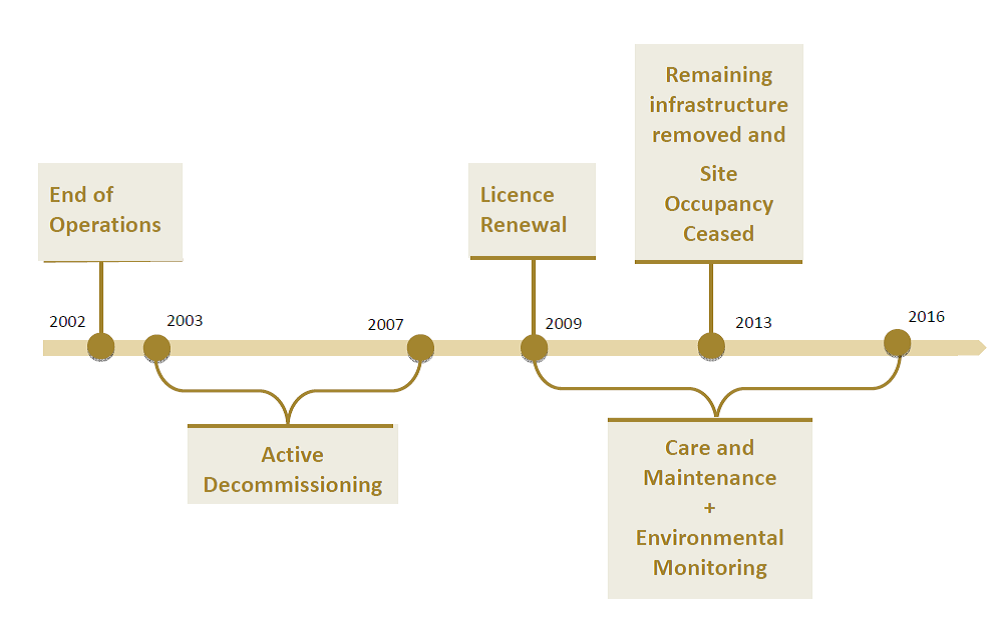

- Port Radium

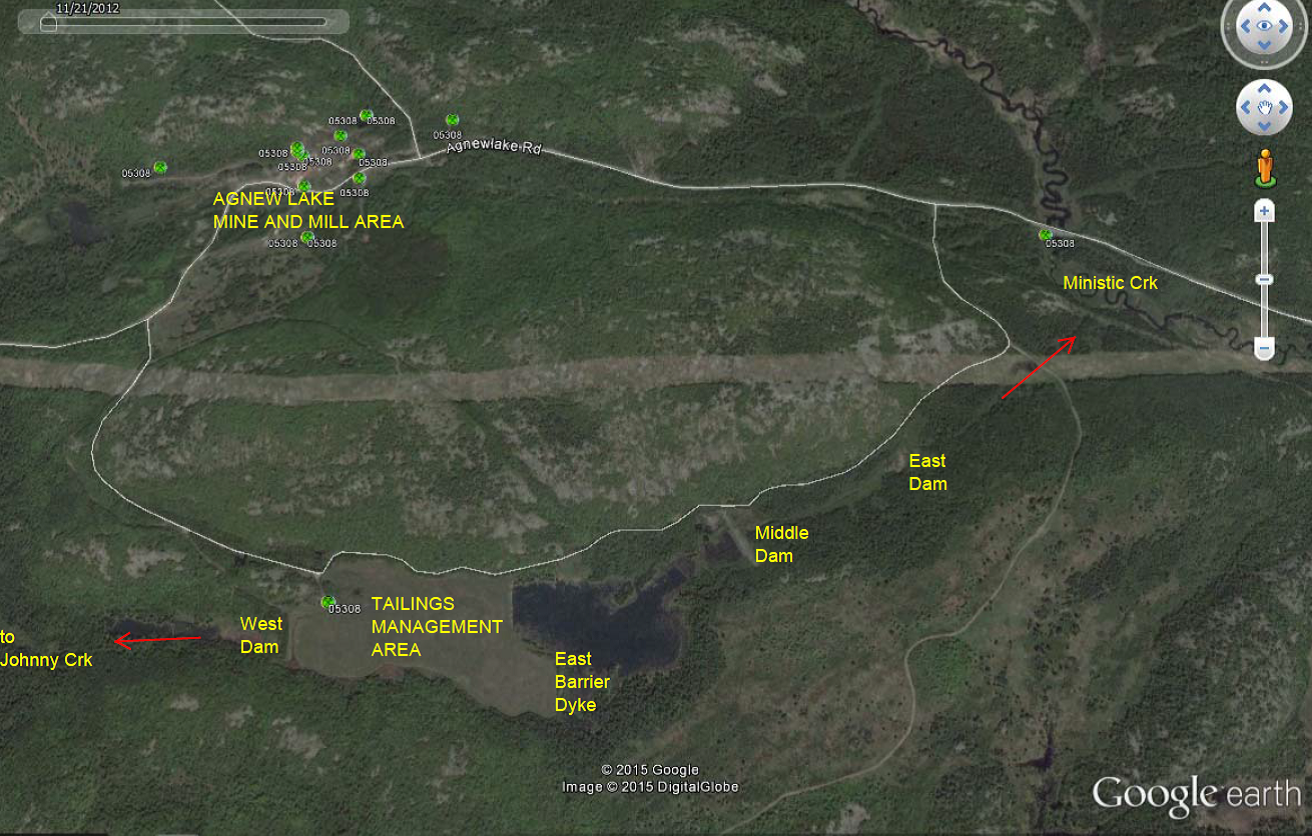

- Agnew Lake

- Madawaska

- Bicroft

- Dyno

- Elliot Lake

- Denison and Stanrock

- Glossary

- Appendix A: Licence and licence conditions handbook

- Appendix B: Safety and control area framework for uranium mines and mills

- Appendix C: Rating methodology and definitions

- Appendix D: Safety and control area ratings (2011–15)

- Appendix E: Financial guarantees

- Appendix F: Worker dose data

- Appendix G: Reportable releases to the environment (spills) and CNSC rating definitions

- Appendix H: Lost-time injuries

- Appendix I: Radiological action level exeedances

- Appendix J: Cluff Lake mid-term update, 2009-15

- Appendix K: Links to websites

- Appendix L: Acronyms and abbreviations

Executive summary

This report, titled Regulatory Oversight Report for Uranium Mines, Mills, Historic and Decommissioned Sites in Canada: 2015, presents CNSC staff’s assessment of the performance of operating, historic and decommissioned uranium mines and mills regulated by the Canadian Nuclear Safety Commission (CNSC). In accordance with the direction of the Commission, the scope of this report has been expanded from the previous edition to include historic and decommissioned sites, to better consolidate and to improve the context of updates provided by staff. The sites added to this report are all low-risk sites, most of which are in long-term monitoring states.

CNSC staff use the safety and control area (SCA) framework to evaluate the performance of each licensee. The report provides performance ratings for all 14 SCAs for operating mines and mills, and where applicable, historic and decommissioned sites. In accordance with previous uranium mines and mills annual reports, this report focuses on the three SCAs which provide the key performance indicators for these facilities: radiation protection, environmental protection, and conventional health and safety. The information provided covers the 2015 calendar year and, where possible, shows trends and compares information to previous years. The report also discusses relevant aspects of the CNSC’s Independent Environmental Monitoring Program, public information and community engagement programs, as well as information on licensees’ operations, major developments and significant events.

The SCA ratings provided in this report were derived from results of regulatory oversight activities conducted by CNSC staff. These activities included onsite inspections, technical assessments, reviews of reports submitted by licensees, event and incident reviews, and ongoing exchanges of information with licensees. For this reporting year, CNSC staff rated all SCAs as satisfactory for all but one regulated site. Only the Deloro mine site was rated below expectations in one SCA. This resulted in CNSC staff issuing an order to the licensee. CNSC staff confirmed that all uranium mine and mill sites in Canada operated safely during 2015.

CNSC staff concluded that each of the regulated sites covered in this report made adequate provisions for the health and safety of the workers, the protection of the public and the environment, and Canada’s international obligations.

1 Introduction

1.1 Background

The Canadian Nuclear Safety Commission (CNSC) regulates Canada’s operating, historic and decommissioned uranium mines and mills to protect health, safety, security and the environment; to implement Canada’s international commitments on the peaceful use of nuclear energy; and to disseminate objective scientific, technical and regulatory information to the public.

The CNSC acts in accordance with the requirements of the Nuclear Safety and Control Act (NSCA), and its associated regulations. Each year, the CNSC produces a regulatory oversight report on the operating performance of Canada’s uranium mines and mills licensees and licensed facilities. The scope of previous regulatory oversight reports has been limited to operating facilities. During the 2015 Commission meeting on the Beaverlodge update, Commission members requested that annual updates on historic and decommissioned uranium mine and mill sites be similarly combined into a single report. CNSC staff have compiled all pertaining updates into this report. It describes:

- the CNSC’s regulatory efforts, public information and community engagement, and Independent Environmental Monitoring Program

- the safety and control areas (SCAs) performance rating for operating, historic and decommissioned uranium mine and mill sites regulated by the CNSC

- licensee information on operation, licence changes, major developments and significant events

- performance data on the SCAs of radiation protection, environmental protection, and conventional health and safety for each licensed facility

This report summarizes CNSC staff’s assessment of the following regulated uranium mine and mill sites:

- operating facilities

- Cigar Lake

- McArthur River

- Rabbit Lake

- Key Lake

- McClean Lake

- historic (remediating) sites

- Gunnar

- Lorado

- Deloro

- decommissioned sites

- Beaverlodge

- Cluff Lake

- Rayrock

- Port Radium

- Agnew Lake

- Madawaska

- Bicroft

- Dyno

- Elliot Lake

- Denison and Stanrock

The information presented covers the 2015 calendar year and, where possible, makes comparisons to previous years and shows trends. The information available is related to the amount of regulatory effort. The CNSC applies a risk-informed approach which is discussed further in the next section.

1.2 CNSC regulatory efforts

1.2.1 Licensing and compliance

The CNSC ensures licensee compliance through verification, enforcement and reporting activities. An approved licence will contain the terms of the licence, the activities licensed and licence conditions. Tables summarizing the operating, historic and decommissioned uranium mine and mill licences can be found in appendix A. For operating mines and mills, a licence conditions handbook (LCH) accompanies each licence. Any changes made to the LCHs during 2015 appear in appendix A.

CNSC staff develop compliance plans for each site, commensurate with the risk associated with these facilities. CNSC staff validate the risk assessment of each facility by conducting regulatory activities including onsite inspections, assessments, reviews and evaluations of licensee programs, processes and reports. CNSC staff recognize that the level of risk must be considered to ensure that resources and controls are appropriately allocated and applied. Changes to the compliance plans are made on an ongoing basis in response to events, facility modifications and changes in licensee performance.

In 2015, CNSC staff performed 30 inspections at the five uranium mine and mill facilities and 14 inspections at the historic and decommissioned sites. A breakdown of the number of CNSC staff inspections at the operating mine and mill facilities as well as at the historic and decommissioned sites can be found in sections 2.1 and 8.1, respectively. The findings from these inspections were provided to the licensees in detailed inspection reports. Enforcement actions arising from the findings were recorded in the CNSC regulatory information bank to ensure these actions were tracked to completion. CNSC staff have verified that licensees have complied with the conditions of enforcement actions and that all actions have been closed.

1.2.2 Safety and control area framework

CNSC staff use the SCA framework in evaluating each licensee’s safety performance. The framework includes 14 SCAs which are further subdivided into specific areas that define its key components. Appendix B provides definitions of these SCAs and their specific areas.

CNSC staff assess licensee performance in each applicable SCA according to the following four ratings:

- FS – fully satisfactory

- SA – satisfactory

- BE – below expectations

- UA – unacceptable

A discussion of rating methodologies and definitions appears in appendix C.

This report provides operating uranium mines’ and mills’ performance ratings for all 14 SCAs and, where applicable, for the historic and decommissioned sites. It focuses on radiation protection, environmental protection and conventional health and safety, the three SCAs which cover many of the key performance indicators for these facilities and sites.

Through 2015, all SCA performance ratings for the uranium mine and mill facilities, historic and decommissioned sites were rated “satisfactory”, with the exception of the Deloro mine site which received a rating of “below expectations” in management systems. An order was issued to the licensee as a result.

In 2015, results from regulatory oversight activities conducted by CNSC staff concluded that uranium mine and mill facilities and historic and decommissioned sites met the following performance expectations:

- Radiation protection measures were effective and results remained as low as reasonably achievable (ALARA). No worker exceeded regulatory effective dose limits.

- Environmental protection programs were effective, and emissions and effluents remained ALARA.

- Conventional health and safety programs continued to protect workers.

Appendix D contains the SCA performance ratings for the operating mines and mills from 2011 to 2015.

1.2.3 CNSC Independent Environmental Monitoring Program

Under the NSCA, each licensee is required to develop, implement and maintain an environmental monitoring program to demonstrate the public and environment are protected from emissions related to the facility’s nuclear activities. The results of these monitoring programs are submitted to the CNSC for compliance verification with applicable guidelines and limits, as set out in regulations that oversee Canada’s nuclear industry.

The CNSC has implemented its Independent Environmental Monitoring Program (IEMP) to confirm that the public and environment around regulated nuclear facilities are safe. The IEMP is a tool that complements the CNSC’s ongoing compliance verification program. It involves taking samples from public areas around the sites, and measuring and analyzing the amount of radiological and hazardous substances in those samples.

In 2014, samples were collected in a number of publicly accessible areas around the Key Lake and McArthur River operations under the CNSC’s IEMP. The results appear on the CNSC’s IEMP Web page. Based on the results obtained, the CNSC confirmed that the public and the environment around the Key Lake mill and McArthur River mine are safe and that there are no health impacts.

A five-year plan for performing IEMPs at operating uranium mines and mills was established in 2015. As part of this plan, a sampling campaign took place around the McClean Lake operation in the summer of 2016. Results will be published on the CNSC’s IEMP Web page.

CNSC staff are currently developing the sampling cycle plan for the remediating and decommissioned sites to ensure that independent monitoring occurs at these sites at appropriate times. During 2015, a three- to five-year cycle plan at the Denison and Rio Algom sites was developed. A number of environmental samples were collected in publicly accessible areas around the city of Elliot Lake/Serpent River watershed as part of this plan. Also under the IEMP, publicly accessible areas around the Deloro mine site were sampled in 2016. The Gunnar mine site will be sampled once the remediation activities are completed. The 2015 IEMP results indicate that the public and the environment in the vicinity of these sites are protected and safe and that there are no adverse environmental and health effects. Results will continue to be provided at the CNSC’s IEMP Web page.

1.3 Public information and community engagement

The CNSC is committed to keeping the public informed of regulatory activities occurring at operating mine and mill facilities, and historic and decommissioned sites. Ongoing CNSC public engagement efforts include publishing newsletters, updating website information and maintaining a social media presence. During public engagement activities, the CNSC often staffs an information booth to provide important information on its regulatory role and mandate, as well as to answer any questions that community members may have.

To ensure licensees provide open and transparent information to the public, in 2013 the CNSC published new regulatory requirements in RD/GD 99.3, Public Information and Disclosure. Under the new requirements, licensees were compelled to maintain and implement public information and disclosure programs. These programs are supported by disclosure protocols, outlining the type of information on the facility or site and its activities to be shared with the public (e.g., incidents, major changes to operations, periodic environmental performance reports) and how that information will be shared. This ensures timely information is effectively communicated about the health, safety and security of persons and the environment and other issues associated with the lifecycle of nuclear facilities. In 2015, CNSC staff confirmed through regulatory oversight activities, that licensees’ implemented programs are in compliance with RD/GD 99.3.

Licensees and CNSC staff continued regular communication with interested communities in 2015. As part of their public information program and outreach activities, licensees and CNSC staff participated in Northern Saskatchewan Environmental Quality Committee meetings and facility tours. The committee represents more than 30 communities throughout the greater northern Saskatchewan region, many of which are Indigenous.

Indigenous engagement

The CNSC is committed to ongoing engagement and relationship building with interested Indigenous communities. In this regard, First Nation and Métis communities with interest in Canada’s uranium mines and mills were provided a copy of this document. The CNSC has also made available, through its Participant Funding Program, financial support for participation in the review of this report. In addition, during 2015, CNSC staff provided interested Indigenous communities with updates on its IEMPs at the mines, mills, historic and decommissioned sites.

To ensure licensees engage Indigenous communities, in February 2016 the CNSC published REGDOC-3.2.2, Aboriginal Engagement, which sets out requirements and guidance for licensees that propose projects which may raise the Crown’s duty to consult. Throughout 2015, licensees continued to host meetings to discuss their operations with Indigenous communities. CNSC staff attended many of these meetings, including participating in a licensee organized high school science fair.

1.4 Mount Polley event – CNSC follow-up

This section provides an update on CNSC staff activities since the Commission presentation in October 2014 in response to the lessons learned from the August 2014 Mount Polley dam breach event.

A breach of the tailings pond dam at the Mount Polley copper/gold mine in British Columbia occurred on August 4, 2014 and 25 million m3 of contaminated water and tailings were released into nearby water bodies. An independent expert panel investigating the cause of event concluded that the main factor contributing to the dam failure was a flaw in the geotechnical investigation and design.

Tailings pond dams are also associated with uranium mines and mills. There are 17 above ground tailings management facilities located at operating and decommissioned uranium mine sites in Saskatchewan and Ontario. In Saskatchewan, there are above ground tailings impoundments at the Key Lake, Rabbit Lake and Cluff Lake mine sites. The tailings in these impoundments are dry, dewatered and consolidated. In Ontario, there are five sites that are water covered; all others are dry.

Immediately after the Mount Polley event, CNSC staff conducted a review of all existing tailings dams at both operating and decommissioned uranium mines. CNSC staff:

- directed licensees to re-evaluate hazards based on present day guidance and methods defining the design basis; licensees concluded that their tailings management areas are operating as designed and that their dams are safe

- performed a detailed technical review of the Mount Polley report and confirmed that uranium tailings dams are protected from similar modes of dam failure

- reviewed all dam safety assessments and confirmed that all uranium mine tailings dams and their associated structures are in good condition and are safe

- carried out focused geotechnical inspections of all dam structures and confirmed site conditions, in addition to carrying out baseline compliance geotechnical inspections

- carried out a systematic review of CNSC regulations and guidance on dam safety and identified no immediate regulatory actions necessary to provide additional protection

Based on their review, CNSC staff concluded that all CNSC regulated dams have safe designs and are not at risk to an event similar to Mount Polley. Nevertheless, CNSC staff expect that future submissions for dams or their safety reviews will be in accordance with Canadian best practice that reflects lessons learned from the Mount Polley incident (e.g., the Canadian Dam Safety Guidelines that are currently being revised by the Canadian Dam Association). CNSC staff will work with licensees on the consideration of these guidelines once they have been updated.

Section I: Operating Uranium Mines and Mills

2 Overview

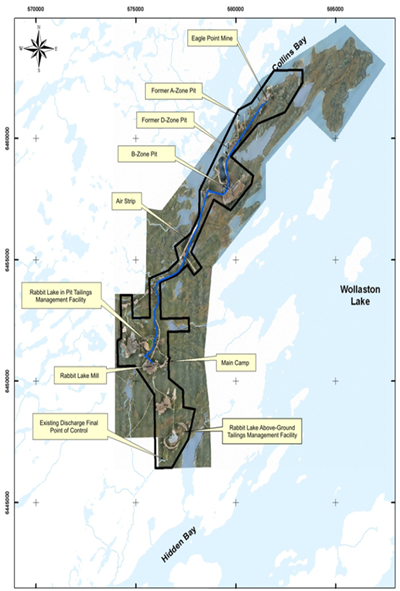

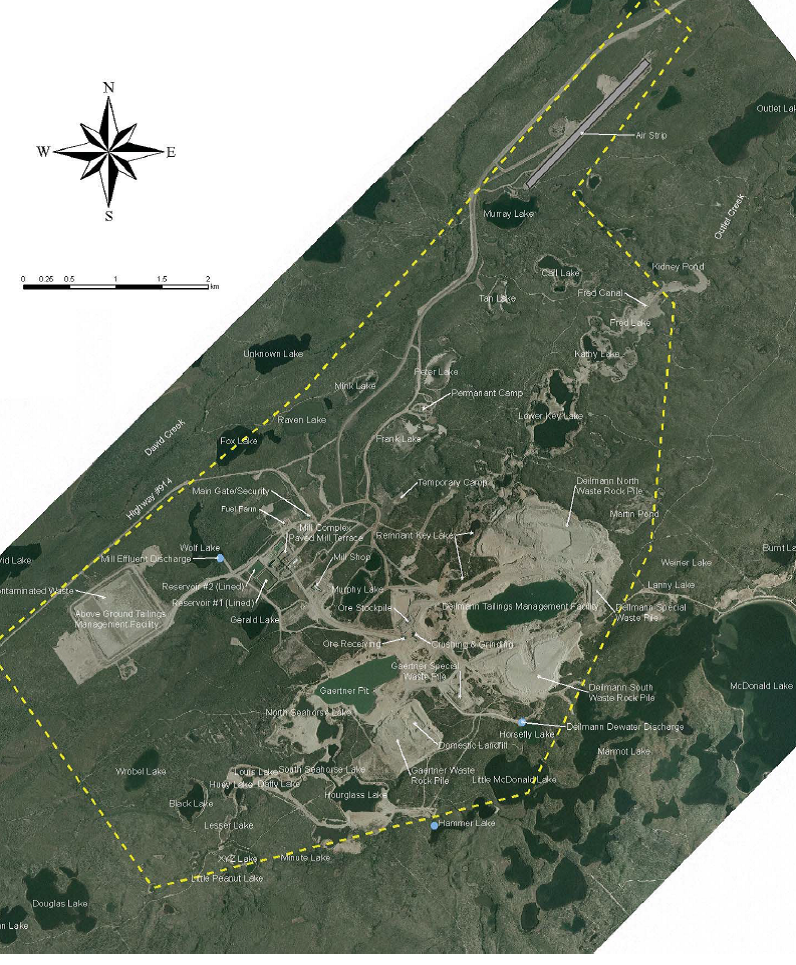

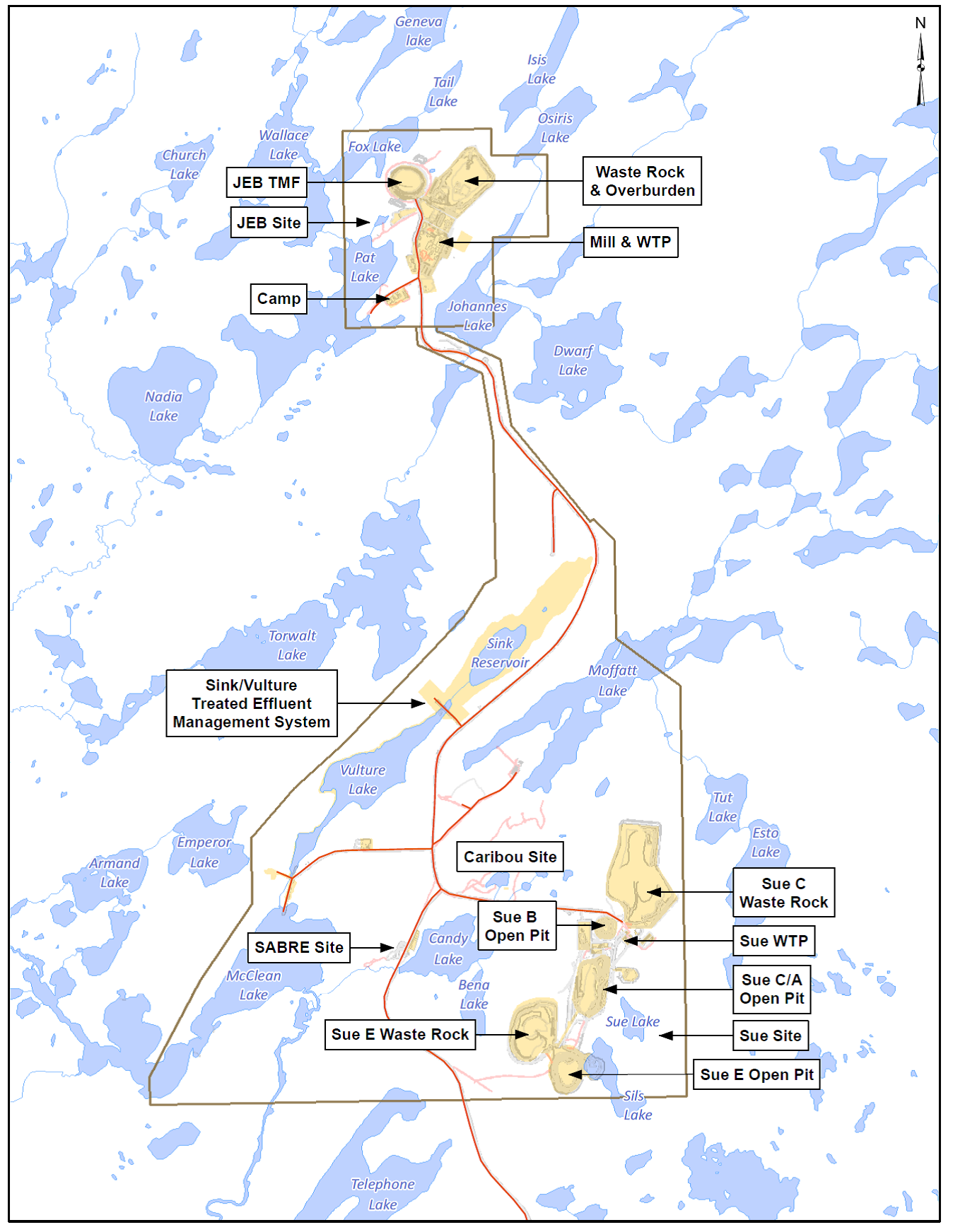

Section I of this report focuses on the uranium mines and mills currently operating in Canada. The facilities listed are located within the Athabasca Basin of northern Saskatchewan and are shown in figure 2.1. They include:

- Cigar Lake mine

- McArthur River mine

- Rabbit Lake mine and mill

- Key Lake mill

- McClean Lake mine and mill

The 2015 uranium production data for these five operating mine and mill facilities is shown in table 2.1. The CNSC confirmed all facilities operated within their authorized annual production limits in 2015.

| Production data | Cigar Lake | McArthur River | Rabbit Lake1 | Key Lake2 | McClean Lake3 |

|---|---|---|---|---|---|

| |||||

| Mining – ore tonnage (tonnes/year) | 26,103 | 88,236 | 309,505 | Not applicable | Not applicable |

| Mining – average ore grade mined (% U expressed as U3O8) | 22.35 | 10.13 | 0.63 | Not applicable | Not applicable |

| Mining – U mined (Mkg U/year) | 4.95 | 7.58 | 1.62 | Not applicable | Not applicable |

| Milling – mill ore feed (tonnes/year) | Not applicable | Not applicable | 313,712 | 165,556 | 25,517 |

| Milling – average mill feed grade (% U expressed as U3O8) | Not applicable | Not applicable | 0.64 | 5.26 | 17.56 |

| Milling – mill recovery (% of U) | Not applicable | Not applicable | 97.14 | 99.35 | 98.99 |

| Milling – U concentrate produced (Mkg U/year) | Not applicable | Not applicable | 1.62 | 7.3 | 4.3 |

| Authorized annual production (Mkg U/year) | 9.25 | 9.6 | 4.25 | 9.6 | 5.0 |

Licensees are required to develop preliminary decommissioning plans and associated financial guarantees to ensure work activities and installations are financially covered and work is guaranteed for completion with no liability to the Government of Canada. Financial guarantee values for the operating mine and mill facilities range from approximately $43 million at the McClean Lake operation to $218 million at the Key Lake operation. The values of the financial guarantees are listed in appendix E.

2.1 CNSC regulatory efforts

The CNSC regulates the five operating mines and mills under separate licences. A list of the licences can be found in appendix A. CNSC staff verified compliance with regulatory requirements through inspections, desktop reviews of reports and licensee programs, which are supplemented with meetings, presentations and facility visits.

CNSC staff performed 30 onsite inspections in 2015 at the five operating uranium mine and mill facilities. These resulted in 34 enforcement actions and 42 recommendations, as shown in table 2.2. The findings resulting from these inspections were provided to the licensees in inspection reports. CNSC staff reviewed and verified that corrective actions taken by each licensee were appropriate and acceptable. All enforcement actions were dealt with appropriately by licensees and are considered closed by CNSC staff.

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | Total | |

|---|---|---|---|---|---|---|

| ||||||

| Number of inspections | 6 | 6 | 6 | 6 | 6 | 30 |

| Estimated inspection person days* | 106 | 102 | 86 | 89 | 118 | 501 |

| Directives** | 0 | 0 | 1 | 0 | 0 | 1 |

| Action notices** | 8 | 3 | 4 | 6 | 12 | 33 |

| Recommendations | 8 | 8 | 3 | 2 | 21 | 42 |

Other regulatory bodies that conduct inspections at the operating facilities include Saskatchewan’s Ministry of Environment and Ministry of Labour Relations and Workplace Safety, and Environment and Climate Change Canada. CNSC staff take into account the findings from these regulatory bodies when assessing licensee performance. When logistically reasonable, joint inspections are conducted with other federal, provincial or territorial regulatory agencies.

2.2 Performance

The SCA performance ratings of the operating mine and mill facilities are presented in table 2.3. For 2015, CNSC staff concluded that the performance of all operating uranium mines and mills was “satisfactory” for all SCAs. Appendix D contains the SCA ratings for each facility from 2011 to 2015.

| Safety and control area | Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|---|

| Management system | SA | SA | SA | SA | SA |

| Human performance management | SA | SA | SA | SA | SA |

| Operating performance | SA | SA | SA | SA | SA |

| Safety analysis | SA | SA | SA | SA | SA |

| Physical design | SA | SA | SA | SA | SA |

| Fitness for service | SA | SA | SA | SA | SA |

| Radiation protection | SA | SA | SA | SA | SA |

| Conventional health and safety | SA | SA | SA | SA | SA |

| Environmental protection | SA | SA | SA | SA | SA |

| Emergency management and fire protection | SA | SA | SA | SA | SA |

| Waste management | SA | SA | SA | SA | SA |

| Security | SA | SA | SA | SA | SA |

| Safeguards and non-proliferation | SA | SA | SA | SA | SA |

| Packaging and transport | SA | SA | SA | SA | SA |

This report focuses on radiation protection, environmental protection and conventional health and safety, the three SCAs that cover many of the key performance indicators for these facilities.

2.3 Radiation protection

Uranium mine and mill licensees in Canada are required to implement and maintain radiation protection programs in accordance with the Radiation Protection Regulations. Each program must ensure that contamination levels and radiation doses received by individuals are monitored, controlled and maintained below regulatory limits and as low as reasonably achievable (ALARA).

For 2015, CNSC staff rated the radiation protection SCA at all five uranium mine and mill facilities as “satisfactory” based on regulatory oversight activities.

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

Radiological hazard control

Sources of radiation exposure at uranium mines and mills include:

- gamma radiation

- long-lived radioactive dust

- radon progeny

- radon gas

These hazards were controlled by licensees’ programs and practices through the effective use of time, distance and shielding, ventilation, contamination control and personal protective equipment.

Radiation protection program performance

CNSC staff conducted regulatory oversight activities in the area of radiation protection (RP) at all operating mine and mill facilities during 2015 in order to verify compliance with regulatory requirements of the licensees’ implementation of their RP programs.

The RP programs include codes of practice that set out licensee administrative levels and action levels for doses of radiation. Action levels are developed, which if reached, may indicate a loss of control of part of a licensee’s RP program and triggers a requirement for specific action to be taken. Licensees are responsible for identifying the parameters of their programs that represent timely indicators of potential losses of control. For this reason, action levels are licensee-specific and may change over time depending on operational and radiological conditions. If an action level is reached, it triggers the licensee to establish the cause and notify the CNSC, and if applicable, to restore the effectiveness of the RP program. The five operating uranium mine and mill facilities listed have the same maximum action level of 1 millisievert (mSv) per week and 5 mSv per quarter of a given year. A brief description of action level exceedances that occurred in 2015 and the corrective actions implemented are provided in appendix I. CNSC staff are satisfied with the actions taken by licensees to address these action level exceedances.

CNSC staff confirmed the RP programs and practices at operating mines and mills continued to be effective in controlling radiological exposure to workers.

Application of ALARA

CNSC staff verified the uranium mine and mill facilities continued to maintain and implement RP programs based on the ALARA principle. These facilities set objectives to keep doses well below the regulatory limit. If action levels were exceeded, they were reported to the CNSC.

Worker dose control

As defined in the NSCA, nuclear energy workers (NEWs), whether permanent employees or contractors, are designated based on work practices and activities. At all operating mines and mills, NEWs are issued optically stimulated luminescence dosimeters (OSLD), which measure external gamma radiation exposure and resulting doses. Where required, workers also wear personal alpha dosimeters (PAD) to measure alpha radiation exposure from radon progeny and radioactive dust. OSLD and PAD readings are measured by a CNSC-licensed dosimetry provider. Where direct monitoring through dosimeters is not warranted, approved dose estimation methods (such as area/group monitoring and time cards) are used in accordance with CNSC regulatory guidance. All licensees met regulatory requirements for the use of licensed dosimetry.

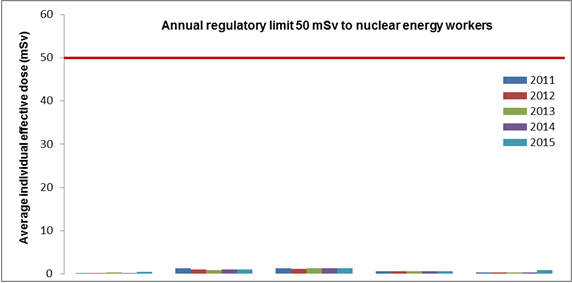

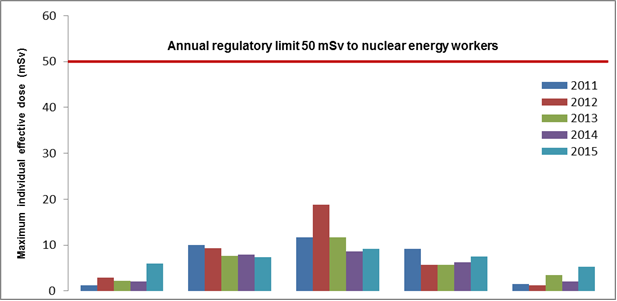

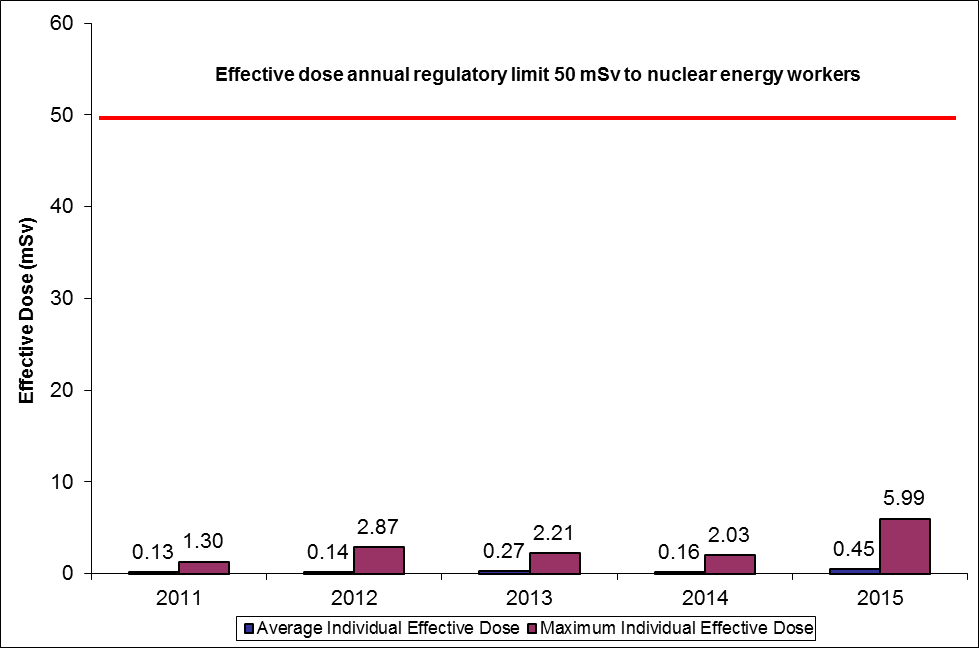

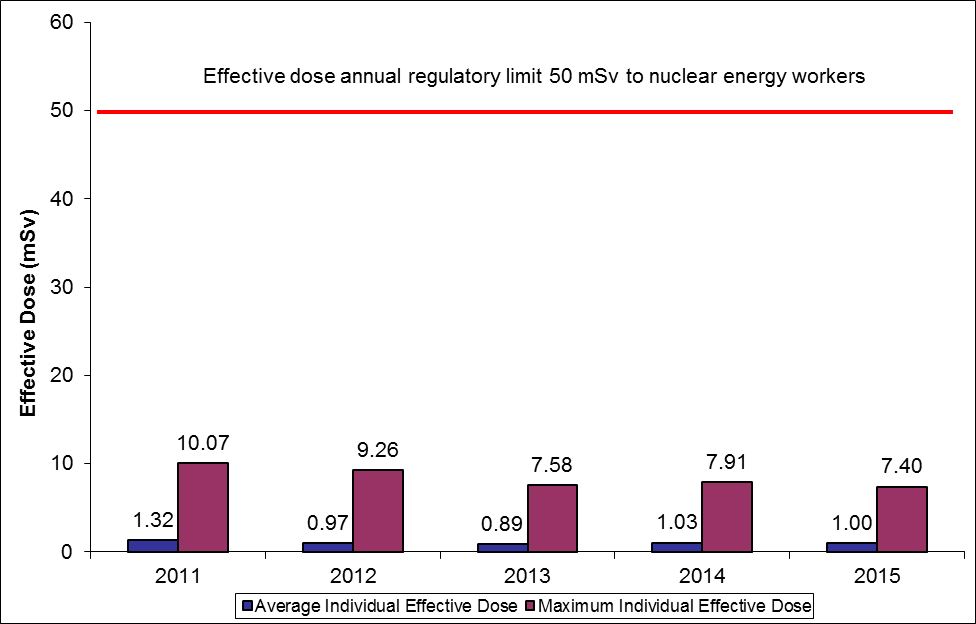

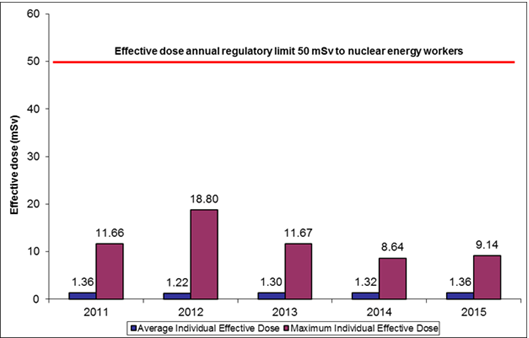

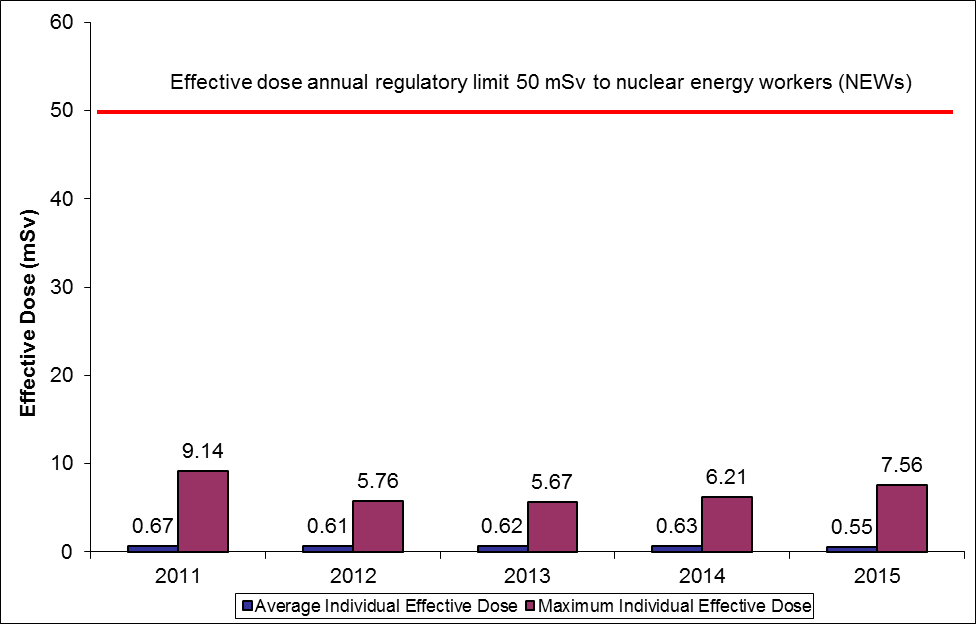

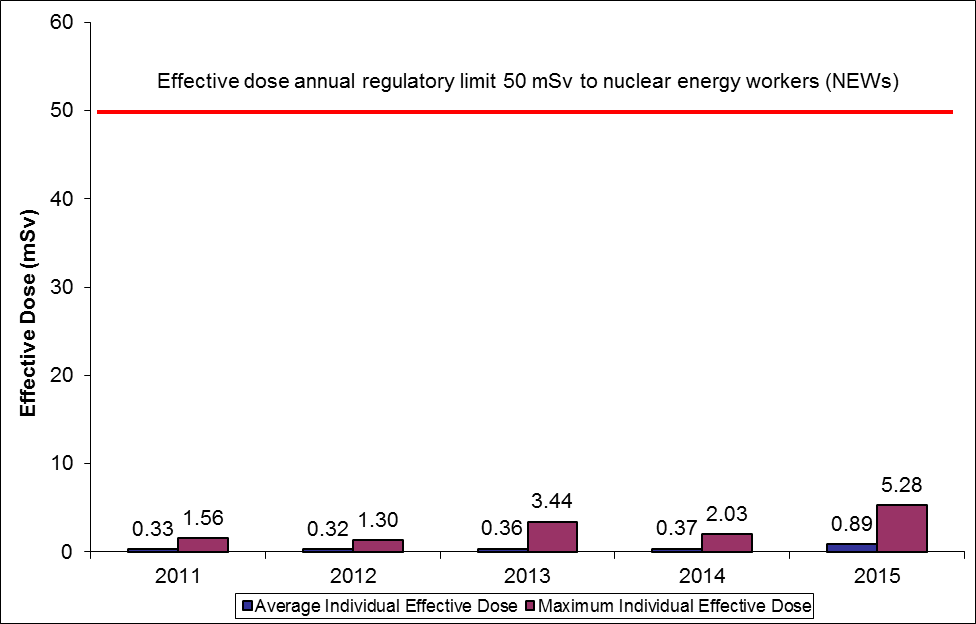

Figures 2.2 and 2.3 show the average individual effective dose and maximum individual effective dose during the 2011 to 2015 reporting period for the five operating mine and mill facilities. In 2015, no worker at any facility exceeded the regulatory individual effective dose limit of 50 mSv in a one-year dosimetry period nor the 100 mSv limit over a five-year dosimetry period.

Description

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2011 | 0.13 | 1.32 | 1.36 | 0.67 | 0.33 |

| 2012 | 0.14 | 0.97 | 1.22 | 0.61 | 0.32 |

| 2013 | 0.27 | 0.89 | 1.30 | 0.62 | 0.36 |

| 2014 | 0.16 | 1.03 | 1.32 | 0.63 | 0.37 |

| 2015 | 0.45 | 1.00 | 1.36 | 0.55 | 0.89 |

| |||||

Description

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2011 | 1.30 | 10.07 | 11.66 | 9.14 | 1.56 |

| 2012 | 2.87 | 9.26 | 18.80 | 5.76 | 1.30 |

| 2013 | 2.21 | 7.58 | 11.67 | 5.67 | 3.44 |

| 2014 | 2.03 | 7.91 | 8.64 | 6.21 | 2.03 |

| 2015 | 5.99 | 7.40 | 9.14 | 7.56 | 5.28 |

In 2015, the highest individual effective dose to a uranium mine and mill worker was 9.14 mSv at the Rabbit Lake operation. The increases to the average individual effective doses and maximum individual effective doses for Cigar Lake operation and McClean Lake operation were due to increased production rates.

Appendix F displays the number of NEWs with the corresponding average individual effective dose and maximum individual effective dose for each operating facility during the 2011 to 2015 period.

Estimated dose to the public

Uranium mine and mill operations are remote from local populations. A public radiation dose limit of 1 mSv per year above natural background radiation has been set to ensure the protection of non-NEWs’ health (including the public). Radiological exposures measured at the licensed facility boundaries are near background radiation levels, ensuring the public is protected.

In 2015, based on the outcome of inspections and reviews of the radiation protection programs, radiological hazard control, worker dose control, and application of ALARA, CNSC staff were satisfied that uranium mine and mill licensees controlled radiation doses to workers at levels well below the regulatory limits, as well as keeping doses ALARA.

2.4 Environmental protection

The environmental protection SCA covers programs that identify, control and monitor releases of radioactive and hazardous substances and effects on the environment from facilities or as a result of licensed activities.

Based on regulatory oversight activities, CNSC staff rated the 2015 performance of all five uranium mine and mill facilities for the environmental protection SCA as “satisfactory”. Environmental protection programs were effectively implemented and met regulatory requirements for all uranium mines and mills.

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

Environmental management system

Licensees develop and maintain environmental management systems which provide a framework for integrated activities related to environmental protection during facility operation. The environmental management systems are described in approved environmental management programs and include activities such as establishing annual environmental objectives, goals and targets. Licensees audit their programs at least once every year. CNSC staff reviewed and assessed the objectives, goals and targets through regular compliance verification activities.

Environmental risk assessment

The CNSC uses site-specific environmental risk assessments (ERAs) as a regulatory tool throughout the lifecycle of uranium mine and mill facilities. Applicants use ERAs during initial environmental assessments for new facilities or for new activities at existing facilities. The ERA identifies mitigation technologies or practices and predicts physical disturbances; releases to the atmosphere, surface water and groundwater; changes to the physical environment and any biological effects that may occur as a result of a new facility or activity. CNSC staff review ERAs to determine the potential risks to human health and the environment and to ensure the implementation of adequate mitigation measures. During operations, CNSC staff periodically review the ERA predictions as criteria for assessing environmental performance.

Assessment and monitoring

Each uranium mine and mill licensee has an environmental monitoring program that monitor releases of nuclear and hazardous substances to the environment and characterize and monitor the quality of the environment associated with the licensed facility.

Environmental monitoring programs set out licensee administrative levels and action levels for controlling effluents released to the environment, as well as assessing potential impacts to the environment. Exceedance of an administrative level indicates that an operating parameter is at the upper range of normal operations. Such an event triggers an internal review by the licensee. Exceedance of an action level indicates a potential loss of control of the environmental protection program which is based on the approved facility design envelope, and triggers actions that must be taken by the licensee to correct the problem. An action level thus provides an early warning system for identifying when there may be potential for major deviations in operating performance outside normal operation that requires notification to the CNSC, an immediate investigation, subsequent corrective actions and preventative measures to be taken in order to restore the effectiveness of the environmental protection program. It is important to recognize that an exceedance of an action level does not imply a potential risk to the environment, but identifies that the operating parameter may be outside the norm based on the facility design. Taking immediate corrective action ensures releases remain lower than the regulatory discharge limits. Facility administrative and action levels are determined through the identification and proper operation of available treatment technologies, as well as facility-specific environmental risk studies.

CNSC staff have reviewed risk assessments and environmental monitoring of uranium mine and mill sites and concluded that the environment is protected.

Protection of the public

According to regulatory requirements, each licensee must demonstrate that the public is protected from exposures to hazardous substances released from the facility. Licensees are required to report to the regulatory authorities, including the CNSC, any unauthorized release of hazardous or radioactive substances to the environment (spills).

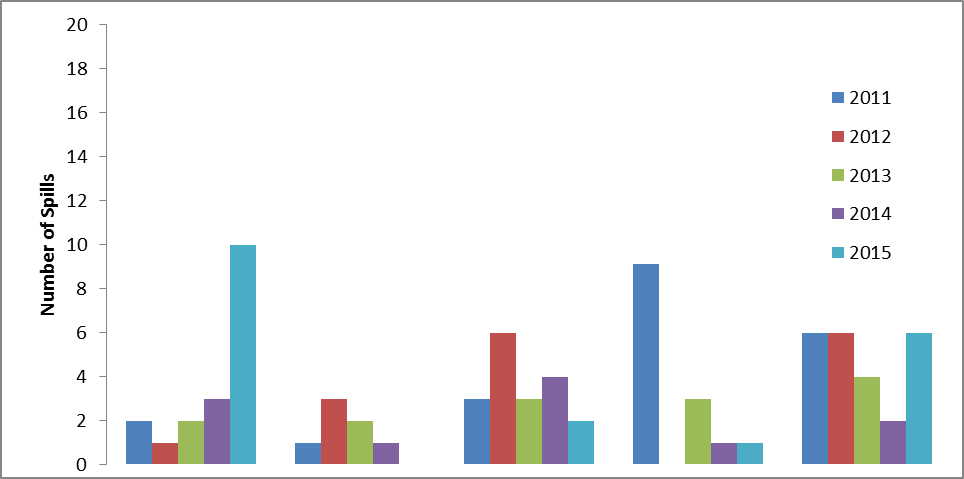

Figure 2.4 depicts the number of environmental reportable spills for uranium mine and mill facilities in 2015. In each case, CNSC staff reviewed the licensee’s actions to ensure effective remediation and prevention, and were satisfied with actions taken by the licensee. The CNSC rated all 2015 spills as “low significance” resulting in no residual impact to the environment.

The site-specific sections and appendix G further describe each reportable spill and any corrective actions taken by the licensee in response to the spill. The CNSC spill rating definitions are also found in appendix G.

Description

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2011 | 2 | 1 | 3 | 9 | 6 |

| 2012 | 1 | 3 | 6 | 0 | 6 |

| 2013 | 2 | 2 | 3 | 3 | 4 |

| 2014 | 3 | 1 | 4 | 1 | 2 |

| 2015 | 10 | 0 | 2 | 1 | 6 |

Effluent and emissions control

Treated effluent released to the environment

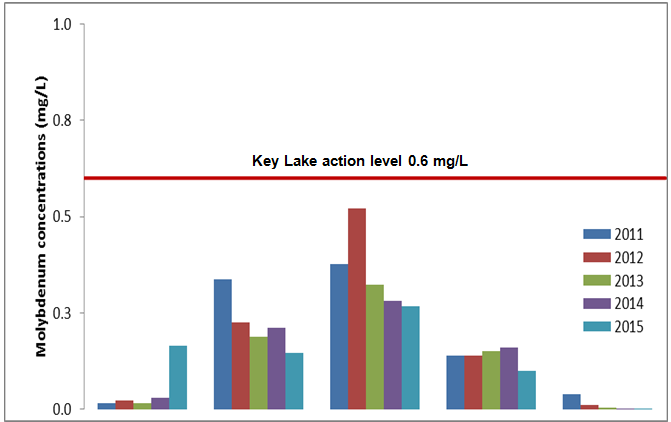

Environmental risk assessments and environmental monitoring data collected prior to 2009 identified releases of molybdenum, selenium and uranium as constituents of potential concern. As a result, licensees were required to improve engineering controls and treatment technologies to reduce effluent releases of these contaminants. In 2015, the treatment technologies implemented continued to keep these contaminant concentrations stable and at acceptable levels. Figures 2.5 to 2.7 display the 2015 average annual effluent concentrations for molybdenum, selenium and uranium at the five operating mine and mill facilities.

In the absence of federal or Province of Saskatchewan limits for molybdenum, the CNSC requires licensees to develop facility-specific effluent controls within their environmental protection program codes of practice. The 2011 to 2015 molybdenum average effluent concentrations for the five facilities were below the Key Lake code of practice action level. The Key Lake action level for molybdenum is the most stringent of the five operating uranium mines and mills and is shown for reference only.

Description

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2011 | 0.0157 | 0.3380 | 0.3760 | 0.1400 | 0.0400 |

| 2012 | 0.0236 | 0.2251 | 0.5220 | 0.1400 | 0.0114 |

| 2013 | 0.0169 | 0.1878 | 0.3240 | 0.1500 | 0.0052 |

| 2014 | 0.0303 | 0.2121 | 0.2820 | 0.1600 | 0.0024 |

| 2015 | 0.1662 | 0.1460 | 0.2680 | 0.1000 | 0.0024 |

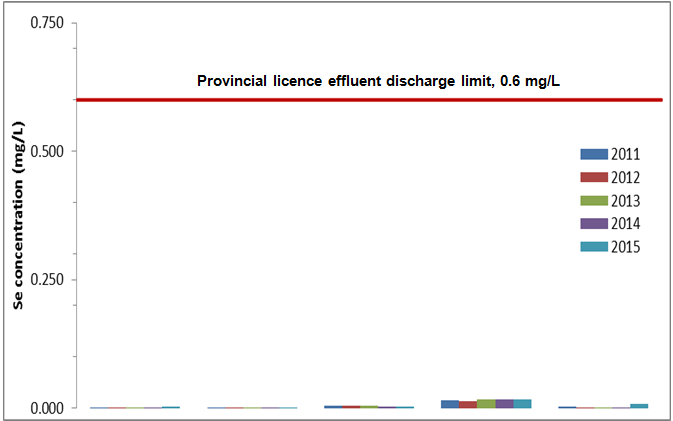

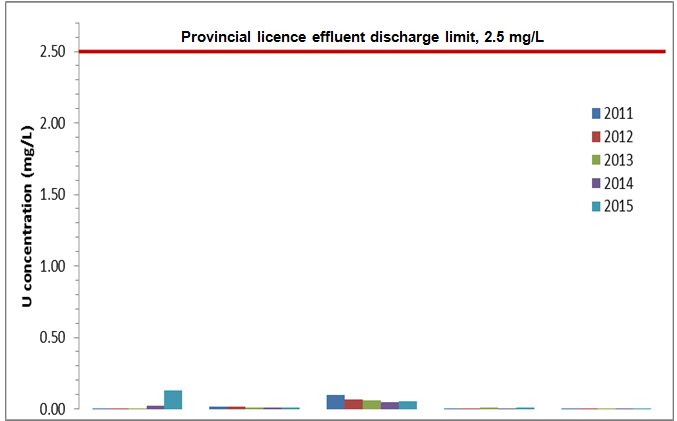

No federal limits are currently established for selenium and uranium in effluent discharge. The Province of Saskatchewan’s licensed effluent discharge limits for selenium and uranium are 0.6 mg/L and 2.5 mg/L, respectively. The CNSC expects performance well below these limits and requires licensees to continually minimize effluent contaminant concentrations to be ALARA. Figures 2.6 and 2.7 demonstrate that both selenium and uranium concentrations in treated effluent that was released to the environment in 2011 to 2015 from operating mine and mill facilities remained below the provincial licence effluent discharge limit.

Description

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2011 | 0.0006 | 0.0023 | 0.0050 | 0.0160 | 0.0040 |

| 2012 | 0.0007 | 0.0016 | 0.0058 | 0.0140 | 0.0014 |

| 2013 | 0.0005 | 0.0014 | 0.0052 | 0.0170 | 0.0004 |

| 2014 | 0.0009 | 0.0017 | 0.0042 | 0.0180 | 0.0007 |

| 2015 | 0.0038 | 0.0025 | 0.0042 | 0.0180 | 0.0092 |

In 2006, a review titled Uranium Effluent Treatment Process identified a concentration of uranium in effluent of 0.1 mg/L as a potential treatment design objective that could be achieved and is protective of the environment. The CNSC uses this value as an interim objective for uranium mine and mill facilities.

At the Cigar Lake operation, increases in uranium concentrations were observed in early 2015 that reflect optimization of operations. Results returned to well below the CNSC’s objective level during the second half of 2015. This is further discussed in section 3.3

Description

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2011 | 0.0002 | 0.0147 | 0.0970 | 0.0050 | 0.0030 |

| 2012 | 0.0006 | 0.0141 | 0.0650 | 0.0060 | 0.0017 |

| 2013 | 0.0011 | 0.0107 | 0.0630 | 0.0080 | 0.0015 |

| 2014 | 0.0193 | 0.0097 | 0.0460 | 0.0060 | 0.0018 |

| 2015 | 0.1310 | 0.0089 | 0.0520 | 0.0080 | 0.0042 |

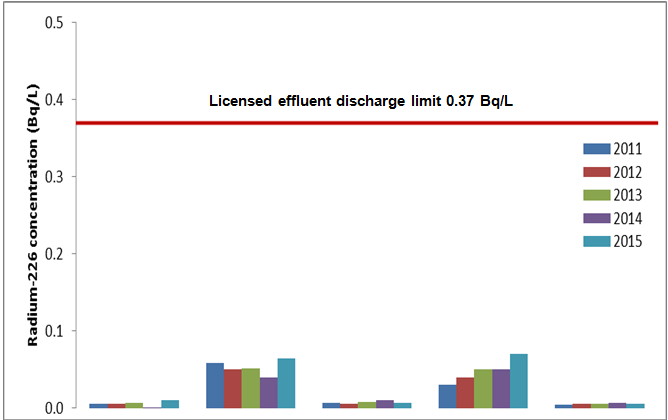

In addition to the above constituents of potential concern, a graph showing concentrations of radium-226 is provided in figure 2.8. The 2011 to 2015 radium 226 annual average effluent concentrations for the five facilities was well below the CNSC’s licence-authorized effluent discharge limit of 0.37 Bq/L.

Description

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2011 | 0.006 | 0.059 | 0.007 | 0.030 | 0.005 |

| 2012 | 0.006 | 0.051 | 0.006 | 0.040 | 0.006 |

| 2013 | 0.007 | 0.052 | 0.008 | 0.050 | 0.006 |

| 2014 | 0.008 | 0.040 | 0.010 | 0.050 | 0.007 |

| 2015 | 0.010 | 0.065 | 0.007 | 0.070 | 0.006 |

Uranium mine and mill facilities also analyze treated effluent for concentrations of various substances, such as arsenic, copper, lead, nickel, zinc, total suspended solids (TSS) and pH. Table 2.4 displays the annual average parameter concentration values in effluent for these substances released in 2015, as well as the discharge limits described in the Metal Mining Effluent Regulations (MMER). All metal mines and mills in Canada are subject to the MMER of the federal Fisheries Act. The CNSC incorporates the effluent limit requirements of the MMER in uranium mine and mill licences. In 2015, all treated effluent released to the environment from licensed mining and milling activities for the above substances met the effluent discharge limits stipulated in the CNSC operating licences and the MMER.

| Parameters | MMER discharge limits | Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|---|---|

| Arsenic (mg/L) | 0.5 | 0.0439 | 0.0029 | 0.004 | 0.006 | 0.0034 |

| Copper (mg/L) | 0.3 | 0.0004 | 0.0011 | 0.0030 | 0.030 | 0.0030 |

| Lead (mg/L) | 0.2 | 0.0001 | 0.0009 | 0.0001 | 0.01 | 0.0001 |

| Nickel (mg/L) | 0.5 | 0.0061 | 0.0035 | 0.0057 | 0.071 | 0.0181 |

| Zinc (mg/L) | 0.5 | 0.0075 | 0.0016 | 0.001 | 0.009 | 0.0006 |

| TSS (mg/L) | 15 | 1.4 | 1.0 | 2.0 | 2.8 | 2.0 |

| pH | 6.0–9.5 | 6.84 | 7.32 | 7.12 | 6.4 | 7.30 |

In 2015, all treated effluent released to the environment from the licensed mining and milling activities met the effluent discharge limits stipulated in the CNSC operating licences.

CNSC staff will continue to review effluent quality results to ensure that effluent treatment performance remains effective.

Air emissions released to the environment

Uranium mines’ and mills’ environmental programs include monitoring the effects of operations on the surrounding air and soil. The licensees measure airborne particulate levels and concentrations of parameters, as well as the concentration of radon gas. They also monitor contaminant concentrations in soil and terrestrial vegetation to verify that operational impacts are minimized and below regulatory limits.

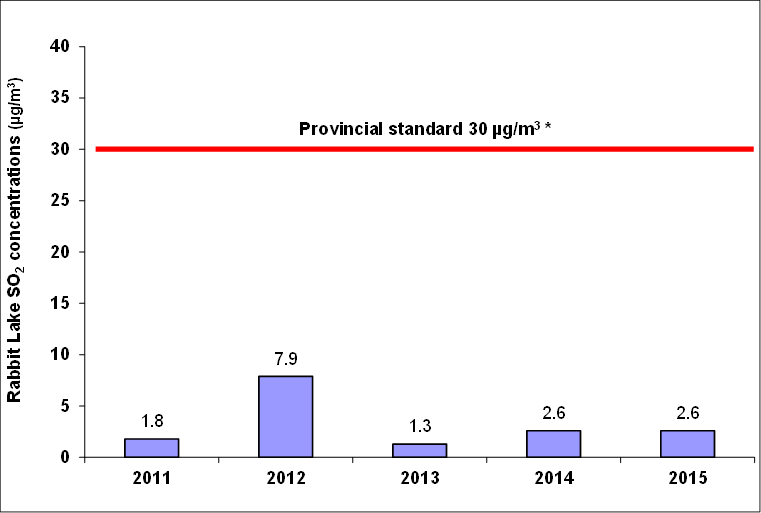

Facilities with milling operations perform stack tests to monitor atmospheric emissions from acid plants, yellowcake dryers, calciner operations, packaging, grinding and ammonium sulphate operations. Other measured parameters (e.g., ambient radon and stack testing for sulphur dioxide, uranium and heavy metals) verify facility design and evaluate the operations against predictions made in environmental risk assessments.

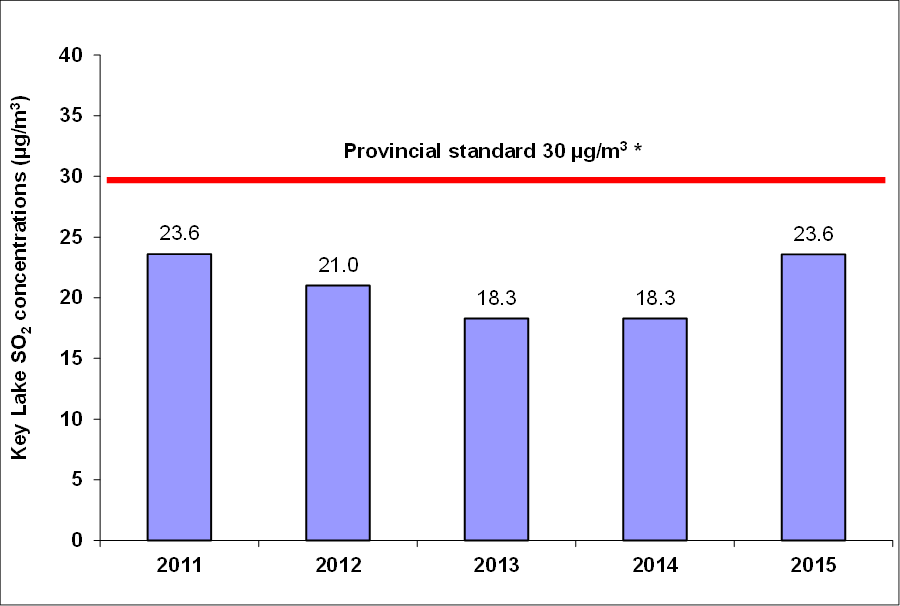

The operating mines and mills have demonstrated satisfactory performance on mitigating and monitoring the effects of their operations on the surrounding air and soil. The air and soil results around the facilities indicate slightly higher than background concentrations for some samples collected in the immediate vicinity of activities; however, the concentrations decrease to background levels within a short distance. The monitoring results indicate negligible impacts from atmospheric releases and confirm all uranium mines and mills are in compliance with their programs and provincial standards.

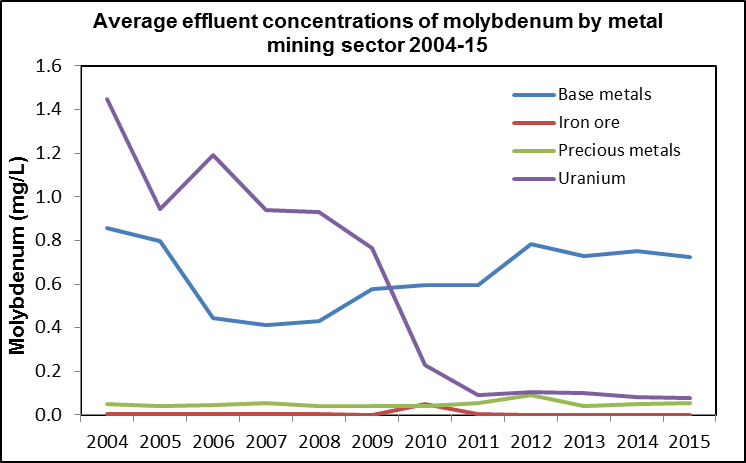

Treated mining/milling effluent: a comparison of the uranium mining sector to other metal mining sectors across Canada

As noted earlier, metal mines and mills in Canada are subject to the MMER of the federal Fisheries Act. Compliance with the MMER limits provides a good effluent treatment comparison of the mining sector to other metal mining sectors across Canada. The effluent treatment quality of the uranium mine and mill facilities compares favourably to other mining sectors of base metal, precious metal and iron mines.

The data used for analysis and comparison is acquired from Environment and Climate Change Canada. MMER data from 2014 is used for comparison within this 2015 report since it is the most current sector-specific MMER information available, with the exception of molybdenum and selenium for which 2015 data is available. The mines reporting under the MMER, and which released treated effluent in 2014, are grouped into four metal mining sectors based on the primary metal produced. The metal mining sectors are:

- uranium – five mines

- base metals (such as copper, nickel, molybdenum or zinc) – 49 mines

- precious metals (such as gold or silver) – 48 mines

- iron – seven mines

Molybdenum is a parameter requiring routine monitoring of treated effluent subject to the MMER. Figure 2.9 shows continuous improvement by the uranium sector in reducing molybdenum in effluent. In 2015, molybdenum concentrations in uranium mining sector effluent were similar to those measured in the effluents of precious metal and iron mines, and less than in the effluents for base metal mines.

In mid-2012, the MMER added the requirement for monitoring selenium. Table 2.5 summarizes the average selenium concentration in treated effluent from each mining sector using data collected since 2012. Selenium concentration in effluent of the uranium sector was similar to that of other metal mining sectors in Canada.

| Metal mining sector (mg/L) | |||||

|---|---|---|---|---|---|

| Year | Uranium | Base metals | Precious metals | Iron | |

| 2012/2013 | 0.003 | 0.005 | 0.005 | 0.001 | |

| 2014 | 0.004 | 0.006 | 0.005 | 0.001 | |

| 2015 | 0.004 | 0.005 | 0.004 | 0.004 | |

Metal Mining Effluent Regulations performance indicators

The MMER specifies the maximum concentration limits in effluent for the following regulated parameters: arsenic, copper, lead, nickel, zinc, radium-226, total suspended solids and an allowable pH range. Effluent must also be non-toxic and pass the trout acute lethality test. The effluent treatment performances of the four metal mining sectors are compared using the following three performance indicators:

1) Compliance with the effluent concentration limits and pH

Table 2.6 illustrates the number of mines out of compliance with MMER effluent standards for at least one regulated parameter (excluding toxicity test in 2014).

This data is used to assess if compliance with the parameters of the MMER is a sector wide concern.

Two base metal mines and one iron mine had effluent with radium concentrations above the MMER limit for portions of the year. The uranium mines were in full compliance with the provisions of the MMER.

| Mining sector | |||||

|---|---|---|---|---|---|

| Parameter | Uranium | Base metals | Precious metals | Iron | |

| |||||

| Arsenic | 0 | 0 | 1 | 0 | |

| Copper | 0 | 2 | 0 | 0 | |

| Lead | 0 | 0 | 0 | 0 | |

| Nickel | 0 | 5 | 0 | 0 | |

| Zinc | 0 | 3 | 1 | 0 | |

| Total suspended solids | 0 | 7 | 5 | 5 | |

| Radium-226 | 0 | 2 | 0 | 1 | |

| pH range | 0 | 3 | 1 | 2 | |

| Number of mines out of compliance with at least one parameter* | 0 | 15 | 8 | 5 | |

| Number of mines | 5 | 49 | 48 | 7 | |

2) Annual average effluent concentrations in the metal mining sectors

Table 2.7 presents the 2014 annual average effluent concentrations for parameters in comparison of the metal mine sectors. CNSC staff note the base metal and iron mines effluent concentration for radium-226 is comparative to uranium mines.

| |||||

| Parameter* | MMER discharge limits | Uranium | Base metals | precious metals | Iron |

|---|---|---|---|---|---|

| Arsenic (mg/L) | 0.5 | 0.004 | 0.007 | 0.034 | 0.0016 |

| Copper (mg/L) | 0.3 | 0.003 | 0.058 | 0.016 | 0.004 |

| Lead (mg/L) | 0.2 | 0.0002 | 0.004 | 0.001 | 0.001 |

| Nickel (mg/L) | 0.5 | 0.019 | 0.187 | 0.021 | 0.007 |

| Zinc (mg/L) | 0.5 | 0.009 | 0.062 | 0.015 | 0.023 |

| TSS (mg/L) | 15 | 1.0 | 4.5 | 5.9 | 27.2 |

| Radium-226 (Bq/L)/th> | 0.37 | 0.020 | 0.024 | 0.009 | 0.020 |

| pH | 6.0–9.5 | 7.0 | 7.7 | 7.5 | 7.3 |

3) Toxicity test results

Effluent toxicity is measured using the rainbow trout acute lethality test. The rainbow trout acute lethality test has become the world standard toxicity test for fresh-water, cool-climate conditions and has been part of Canadian regulations and guidelines for three decades. In this test, rainbow trout fingerlings or swim-up fry (0.3 g to 2.5 g wet weight) are reared under controlled conditions. They are then placed in undiluted effluent for 96 hours. If fewer than half of the fish survive, the effluent is deemed acutely lethal. Effluent must be non-acutely lethal to pass the test as a requirement of the MMER.

Table 2.8 displays the number of pass and fail results of the rainbow trout acute lethality tests for the metal mining sectors in 2014. The uranium mining metal sector passed all required tests in 2014.

| MMER limit | Uranium | Base metals | Precious metals | Iron | |

|---|---|---|---|---|---|

| Rainbow trout acute-lethality test | Pass | 31 | 392 | 383 | 162 |

| Fail | 0 | 3 | 4 | 3 |

A mine is considered compliant if, throughout the year, the effluent passes all trout acute lethality tests. Table 2.9 summarizes the performance of the metal mining sectors. As shown in table 2.9, the uranium mine and mill facilities passed all acute lethality tests from 2010 to 2014.

| Metal mining sector | 2010 | 2011 | 2012 | 2013 | 2014 |

|---|---|---|---|---|---|

| Uranium | 100% | 100% | 100% | 100% | 100% |

| Base metals | 90% | 85% | 98% | 93% | 98% |

| Precious metals | 96% | 96% | 94% | 86% | 96% |

| Iron | 80% | 83% | 100% | 100% | 71% |

Eastern Athabasca Regional Monitoring Program

The Eastern Athabasca Regional Monitoring Program (EARMP) was established by the Province of Saskatchewan in 2011. It monitors the safety of traditionally harvested country foods through analysis of water, fish, berries and mammal chemistry from representative northern Saskatchewan communities. The program contractor is a northern Saskatchewan Indigenous-owned business. Community members take part in the monitoring program by collecting samples. Harvesting and consuming traditional country foods are an important part of the culture in northern Saskatchewan. The intent of the EARMP is to provide confidence and transparent communication with community members that traditional country foods remain safe to eat today and for future generations. The complete report and data is available at earmp.ca.

CNSC staff support the EARMP and are working towards collaboration opportunities on this valuable program, which may include using the Participant Funding Program to further promote community involvement.

The evaluation of the country food data from previous years, leading up to five years of data collection, has confirmed that operating uranium mines and mills are not affecting the safety of country foods at nearby communities. The results indicated that radiological and non-radiological exposures to residents from consuming country foods were similar to exposures of the general Canadian population and were below values that are considered to be protective of health effects.

2.5 Conventional health and safety

The conventional health and safety SCA covers the implementation of a program to manage workplace safety hazards and protect personnel and equipment. Uranium mines and mills must develop, implement and maintain effective safety programs to promote safe and healthy workplaces and minimize incidences of occupational injuries and illnesses.

For 2015, CNSC staff rated the conventional health and safety SCA at the uranium mine and mill facilities as “satisfactory” based on regulatory oversight activities.

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

Practices

Licensees are expected to identify potential safety hazards, assess associated risks, and introduce the necessary materials, equipment, programs and procedures to effectively manage, control and minimize these risks. CNSC staff work with Saskatchewan Ministry of Labour Relations and Workplace Safety to provide regulatory oversight of conventional health and safety in uranium mines and mills. CNSC staff’s compliance verification activities include inspections, reviews of compliance reports and health and safety events. CNSC staff confirmed the mine and mill facilities implemented effective management of conventional health and safety in their activities.

Awareness

CNSC staff observed that the conventional health and safety programs at the facilities continued to provide education, training, tools and support to workers. Each facility promotes the notion that safety is the responsibility of all individuals. This message is reinforced by management, supervisors and workers. Management stresses the importance of conventional health and safety through regular communication, management oversight, and continual improvement of safety systems. CNSC staff concluded that facilities are committed to accident prevention, safety awareness and focus on safety culture (see figure 2.10).

Performance

A key performance measure for conventional health and safety is the number of lost-time injuries (LTIs) that occur per facility. A LTI is a workplace injury that results in the worker being unable to return to work for a period of time. In reviewing LTIs, CNSC staff also consider the injury’s severity and frequency rates. Table 2.10 shows the number of LTIs at the uranium mine and mill facilities along with severity and frequency rates, and the number of full-time equivalent (FTE) workers onsite during 2015.

| Total number of FTE workers and LTI statistics | Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|---|

| ||||||

| Total number of FTE workers1 | 602 | 749 | 610 | 505 | 793 | |

| Number of LTIs2 | 4 | 0 | 2 | 0 | 3 | |

| Severity rate3 | 17.06 | 0 | 55.3 | 0 | 27.7 | |

| Frequency rate4 | 0.56 | 0 | 0.33 | 0 | 0.4 | |

During 2015, there were three LTIs at the McClean Lake operation, two at the Rabbit Lake operation, four at the Cigar Lake operation and none at the McArthur River and Key Lake operations. Appendix H describes the 2015 LTIs and corrective actions taken by each licensee. CNSC staff and Saskatchewan Ministry of Labour Relations and Workplace Safety monitor and review each reportable injury to ensure the cause is identified and satisfactory corrective actions are taken. When applicable, injury information is shared amongst the facilities for lessons learned to improve safety. The injury statistics demonstrate satisfactory performance of the uranium mine and mill operations to keep workers safe from occupational injuries.

Lost-time incidents – comparison of uranium mine and mill performance to other mining sectors

Table 2.11 displays the various safety statistics of mining sectors within Saskatchewan. The uranium mining and milling sector exhibits similar performance to other mining sectors for LTIs and frequency rate when contractors are excluded. The uranium sector is compared excluding contractors because statistics for the other sectors do not include contractors. The uranium mines and mills were the worst performer in severity rate meaning that their LTI’s resulted in the most lost-time work due to injuries. However, a favorable comparison of frequency rate is displayed by the uranium mines and mills.

| Mining sector | Number of LTIs | Frequency rate (200,000 person-hours) | Severity rate (200,000 person-hours) | ||

|---|---|---|---|---|---|

| |||||

| Potash (underground) | 14 | 0.3 | 15.8 | ||

| Solution (potash) | 1 | 0.2 | 0.4 | ||

| Minerals (sodium sulphate, sodium chloride) | 1 | 0.6 | 18.5 | ||

| Hardrock (gold, diamond) | 6 | 0.3 | 0.4 | ||

| Coal (strip mining) | 4 | 0.8 | 20.5 | ||

| Uranium | 4 | 0.3 | 25.0 | ||

| Uranium** (including contractors) | 8 | 0.3 | 20.0 | ||

2.6 Significant events

Key Lake mill calciner event – CNSC follow up

In January and February 2015, two Key Lake mill events resulted in exceedances of the weekly dose action levels and were reported to the Commission as event initial reports. These events were related to malfunctions and component failures with the existing vertical calciner.

The first event occurred on January 14, and was reported to the Commission at the February 4 Commission meeting. Following the event, CNSC staff completed an inspection. Repairs to the calciner were conducted, and the licensee, Cameco, developed a safe startup plan that included enhanced radiation monitoring as required by CNSC staff. The mill was safely restarted on January 21, 2015 with monitoring data showing no evidence of recurrent contamination. CNSC staff continued to review the situation through ongoing monitoring reports.

On February 16, there was a second event involving the same calciner, although the causes were not the same. As a result, the mill, including the calciner, was immediately shut down, and the event reported to the CNSC. CNSC staff conducted an inspection of this event verifying the initial assessment of cause, corrective actions taken and Cameco’s safe startup plan. CNSC staff were satisfied with the corrective actions.

CNSC staff conducted follow-up compliance verification inspections at the Key Lake operation and assessed the corrective actions are acceptable. Details of these events and corrective actions taken by the licensee are found in appendix I.

Following the February event, CNSC staff issued requests according to subsection 12(2) of the General Nuclear Safety and Control Regulations to all operating uranium mills in order to obtain the following information:

- design and operational features that help prevent unplanned release of yellowcake

- equipment, processes and procedures that monitor and identify any weakening of containment systems that might lead to unplanned release of yellowcake

- radiation monitoring equipment and procedures that will quickly identify any unplanned release of yellowcake

- reports on corrective actions and implementation schedules for short-term and long-term measures to address any significant gaps

Onsite inspections were conducted at Key Lake in July 2015 to verify the 12(2) responses were being implemented. These inspections confirmed that the commitments made by the Key Lake licensee in its follow up to the reportable events were being addressed. Corrective actions identified from the event investigations were tracked and implemented by Cameco using their internal corrective action program. Cameco’s corrective actions included improvements to engineering controls, and enhanced radioactive dust and contamination monitoring was implemented to provide additional surveillance to the calciner area. Based on the above corrective actions and commitments made by Cameco in its response to the 12(2) request, and CNSC staff verification activities, CNSC staff considered the 12(2) response acceptable.

In response to the CNSC subsection 12(2) request, AREVA’s McClean Lake operation submitted a preliminary response providing an overview of the calcining circuit and explaining the differences between the Key Lake and the McClean Lake calcining circuits. AREVA later provided a detailed report of its calciner operations, including corrective actions to enhance worker protection, which CNSC staff reviewed and found acceptable. A subsequent follow-up inspection verified implementation of corrective actions taken by AREVA at the McClean Lake operation. CNSC staff were satisfied that AREVA took appropriate steps to avoid similar incidences that had occurred at Key Lake.

Cameco’s Rabbit Lake operation does not use a calciner, but uses a drier in preparing yellowcake product for packaging. Notwithstanding this, CNSC site inspections verified the safe state of yellowcake processes, improved air and radiation monitoring measures, and that lessons learned from the Key Lake event had been applied at the Rabbit Lake operation. CNSC staff were satisfied with the responses and corrective actions taken by Cameco.

In September 2016, the CNSC sent letters to Cameco and AREVA formally verifying acceptance of the actions taken in response to the 12(2) requests. CNSC staff will continue to monitor the calciner and drying operations through compliance inspections and reviews.

Saskatchewan forest fires, 2015

Forest fires in northern Saskatchewan occur annually as part of the natural ecosystem. In 2015, the number of fires and areas burned were significantly higher than the 10-year average. These fires affected a large portion of northern Saskatchewan, either through the impact of smoke on air quality, disruptions to normal business activities, or the direct safety of several northern communities. Most of the fires were located to the south of the operating uranium mines and mills. A number of the 13,000 people evacuated from the northern communities were uranium mine and mill workers. Figure 2.11 shows an example of firefighting efforts that took place in northern Saskatchewan.

Licensees have CNSC-approved emergency management programs that outline practiced responses to emergency situations including wildfires. Facilities have firefighting equipment and personnel are trained to respond to site emergencies, including fires.

Although there were no fires in close proximity to uranium mine and mill operations that required firefighting efforts, licensee corporate crisis management plans were activated to manage delays in the transportation of personnel and critical supplies.

The CNSC monitored the fire situation closely providing regular updates to senior management and posting information on its internal and external websites. A fire status update was also provided at the August 20, 2015 Commission meeting.

3 Cigar Lake Operation

Cameco Corporation operates the Cigar Lake mine located approximately 660 kilometres north of Saskatoon, Saskatchewan. The Cigar Lake operation, shown in figure 3.1, is the world’s second-largest known high-grade uranium deposit, second to Cameco’s McArthur River operation.

The Cigar Lake orebody was discovered in 1981. The first mine shaft was completed in 1990 to support underground exploration and testing of mining methods. A construction licence was granted in late 2004 after the completion of an environmental assessment.

On April 3, 2013 a public Commission hearing was held in Saskatoon for the renewal of the Cigar Lake licence. The Commission issued an eight-year licence valid from July 1, 2013 to June 30, 2021.

Table 3.1 shows mining production data for 2011 through 2015. Ore mining rates and grades were ramped up during 2015 to achieve scheduled production.

| Mining | 2011 | 2012 | 2013 | 2014 | 2015 | |

|---|---|---|---|---|---|---|

| Conversion factor of 2.599779167 lbs of U3O8 | ||||||

| Ore tonnage (tonnes/year) | No mining | No mining | 234 | 3,318 | 21,603 | |

| Average ore grade mined (% U3O8) | No mining | No mining | 1.40 | 7.2 | 22.35 | |

| Uranium mined (Mkg* U/year) | No mining | No mining | 0.04 | 0.20 | 4.95 | |

| Authorized annual production (Mkg U/year) | No mining | No mining | 9.25 | 9.25 | 9.25 | |

Uranium ore is ground into ore slurry, loaded into containers and transported to the McClean Lake operation for milling. Through 2015, there were 2,340 shipments transporting 12,038,319 pounds of uranium concentrate to the McClean Lake mill. As of December 31, 2015 the proven and probable reserves at the Cigar Lake operation amounted to 84.8 million kilograms of uranium.

Surface construction activities in 2015 included upgrades to the modular freeze plant, and surface preparation and tree clearing for construction of the new surface freeze pad scheduled to be completed in 2016. The mine design was modified in March 2015 to accommodate the surface freeze operations.

Commissioning activities for process areas were completed in early 2015. On May 22, the Cigar Lake operation formally announced that it had met all criteria necessary to achieve commercial production including production cycle times and process specifications. In June, a third jet-boring system was also commissioned. No major concerns were reported to CNSC staff during the commissioning of mining activities. In early 2017, Cameco will make a formal report to the Commission on the results of its commissioning activities.

3.1 Performance

The Cigar Lake SCA ratings for the five-year period, 2011 to 2015, are shown in appendix D. For 2015, CNSC staff rated all 14 SCAs for Cigar Lake as satisfactory. This report focuses on radiation protection, environmental protection and conventional health and safety, the three SCAs that cover many of the key performance indicators for these facilities.

3.2 Radiation protection

For 2015, CNSC staff continued to rate the radiation protection SCA as satisfactory based on regulatory oversight activities.

| 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

Radiological hazard control

The main source of radiological exposure at the Cigar Lake operation is from mining and processing of high-grade uranium ore. The effective dose contributors to workers at Cigar Lake were as follows: radon progeny (42.1 percent), gamma radiation (39 percent) and long-lived radioactive dust (LLRD) (18.9 percent). Radon progeny is controlled through ventilation, gamma radiation is controlled through the effective use of time, distance and shielding, and LLRD through ventilation, contamination control and personal protective equipment.

Radiation protection program performance

In 2015, the radiation protection program and practices at the Cigar Lake operation continued to be effective in controlling radiological exposure to workers. There were no effective dose action levels or regulatory exceedances at the Cigar Lake operation in 2015.

Application of ALARA

CNSC staff have verified through regulatory oversight activities that Cameco continues to maintain worker exposures ALARA. To ensure worker exposures are optimized during production increases at Cigar Lake, Cameco has established production-based dose targets to monitor worker exposures. Additional workplace monitoring has been established to identify further opportunities for improvement as various grades and amounts of ore are processed. To date, worker exposures are consistent with expected values. In addition, Cameco continues to implement enhanced exposure monitoring for workers in higher dose categories. The CNSC concluded that the radiation protection program remains effective in ensuring that maximum individual exposures remain ALARA.

Worker dose control

During 2015, the average individual effective dose for NEWs was 0.45 mSv and the maximum individual effective dose was 5.99 mSv. This is an increase from previous years, attributed to transitioning from a construction and commissioning activities to an operating mine. Figure 3.2 displays the average individual effective dose and the maximum individual effective dose for Cigar Lake’s NEWs from 2011 to 2015.

* The effective dose annual limit illustrated applies to the maximum individual effective dose.

CNSC staff are satisfied that the Cigar Lake operation is adequately controlling radiation doses to workers and keeping levels below the regulatory limits.

3.3 Environmental protection

For 2015, CNSC staff continued to rate the environmental protection SCA as satisfactory. The Cigar Lake environmental protection program was effectively implemented and met all regulatory requirements.

| 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

Environmental management system

Cigar Lake’s environmental management system is described in its approved environmental program and includes activities such as establishing annual environmental objectives, goals and targets. CNSC staff reviewed and assessed the objectives, goals and targets through regular compliance verification activities.

Assessment and monitoring

In accordance with Cigar Lake’s environmental protection program, effluent and environmental monitoring, site inspections, environmental awareness training and program implementation audits were performed.

Through compliance activities, CNSC staff concluded that the Cigar Lake operation’s environmental monitoring met regulatory requirements and treated effluent discharge complied with licence requirements during 2015. There were no exceedances of environmental code of practice action levels.

Protection of the public

In 2015, 10 events reported to CNSC staff were submitted as releases of hazardous substances to the environment:

- 57 kg of anhydrous ammonia was released into the atmosphere due to failed condenser coils

- 45 kg of anhydrous ammonia was released into the atmosphere due to failed condenser coils

- 45 kg of anhydrous ammonia was released into the atmosphere due to failed condenser coils

- 453 kg of anhydrous ammonia was released into the atmosphere due to failed condenser coils

- 45 kg of anhydrous ammonia was released into the atmosphere due to failed condenser coils

- 0.010 m3 (10 L) of liquid anhydrous ammonia was released into secondary containment and then vaporized to the atmosphere due to failed condenser coils

- 3 m3 (3,000 L) of mine water was released to the ground through a leaking pipeline

- 730 m3 (730,000 L) of treated effluent was released to the ground through a damaged pond liner

- 19 m3 (19,000 L) of calcium chloride brine was released to the ground due to packer failure in a surface freeze hole

- 0.0005 m3(0.5 L) of liquid anhydrous ammonia was released into secondary containment and then vaporized to the atmosphere due to failed condenser coils

Seven of these 10 events were attributed to failures of condenser coils. These seven failures were due to a combination of extreme temperatures, materials of construction and high load. Cameco has since replaced its aluminum condenser coils with steel. This was confirmed in an August 2016 inspection by CNSC staff. The replaced coils are expected to prevent similar events.

Appendix G contains a brief description of the spills, corrective actions taken by the licensee, CNSC staff’s assessment of those actions and the significance ratings for 2015. CNSC spill rating definitions are also found in appendix G.

Due to timely response and effective corrective actions implemented by the Cigar Lake operation, there were no residual impacts to the environment. CNSC staff were satisfied with Cigar Lake operation’s reporting of spills and the corrective actions taken. The CNSC rated all these spills as low significance. Figure 2.4 displays the number of environmental reportable spills at the Cigar Lake operation from 2011 to 2015.

Effluent and emissions control

Treated effluent released to the environment

At the Cigar Lake operation during the 2011 to 2015 review period, parameter concentrations in treated effluent were low and remained below treated effluent discharge limits.

As discussed in section 2.4, constituents of potential concern (COPC) in treated effluent at the uranium mine and mill facilities are molybdenum, selenium and uranium. At the Cigar Lake operation throughout 2015, concentrations for these constituents (shown in figures 2.5 to 2.7) remained well below their respective action levels or provincial licence effluent discharge limits. At the beginning of 2015, increases in concentrations were observed in these constituents, including exceedances of the uranium objective value. These increases were a result of lower-than-expected pH levels and the volume of mine water being treated in the first quarter of 2015. Following continued optimization of the operation’s waste water treatment system, concentrations returned to typical values during the second half of 2015.

In addition to the COPC, the Cigar Lake operation also analyzed treated effluent for concentrations of various substances such as radium-226, arsenic, copper, lead, nickel, zinc, total suspended solids and pH. As shown in section 2.4, the Cigar Lake operation continues to meet the MMER discharge limits.

The CNSC will continue to review effluent quality results to ensure that effluent treatment performance remains effective.

Air emissions released to the environment

The Cigar Lake operation also maintains an air and terrestrial monitoring program. Atmospheric monitoring at the Cigar Lake facility includes ambient radon, total suspended particulate (TSP), soil sampling and lichen sampling to assess the impact of air emissions.

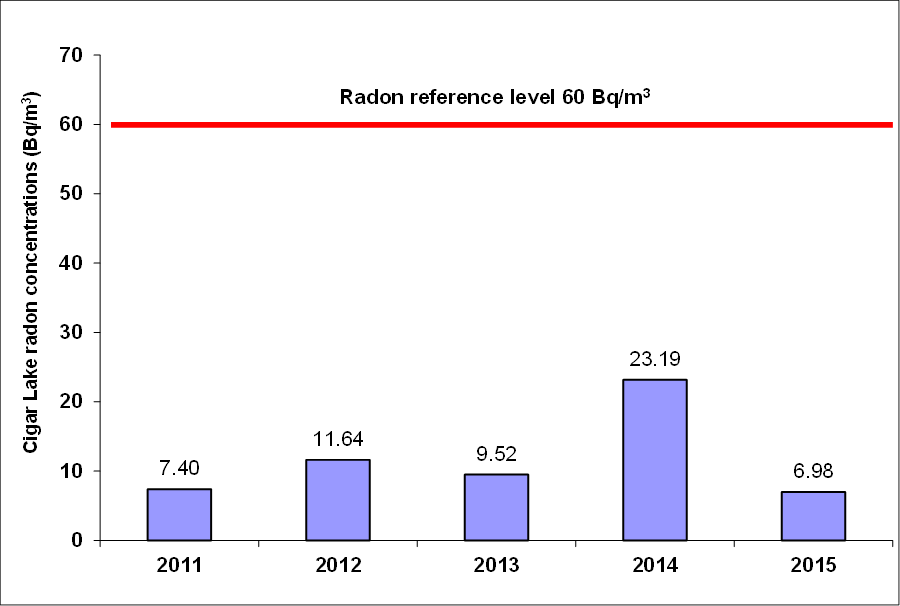

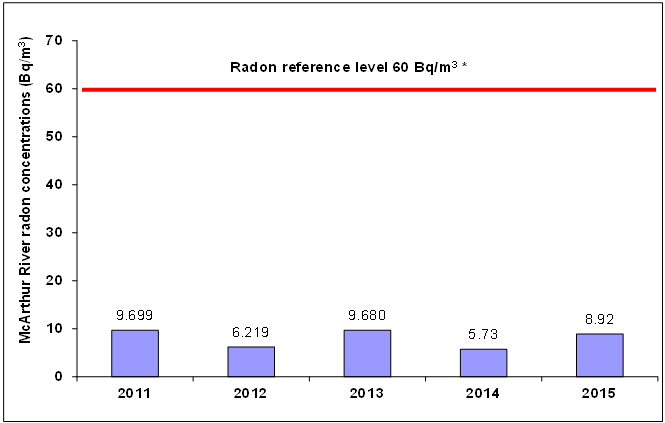

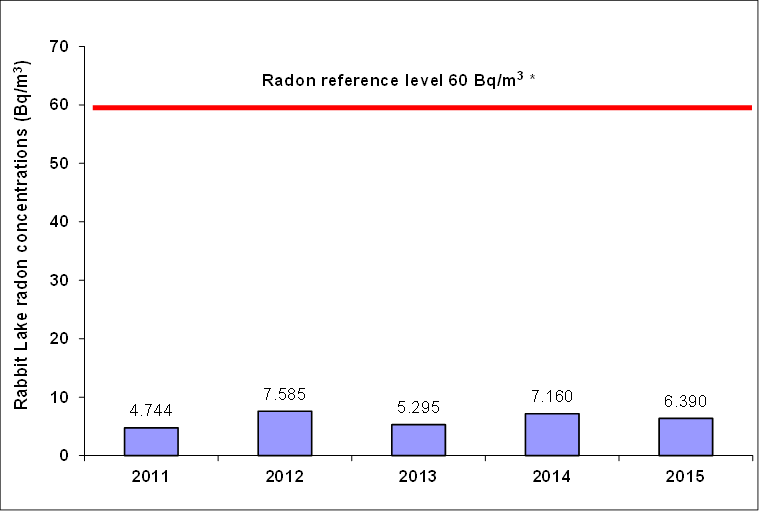

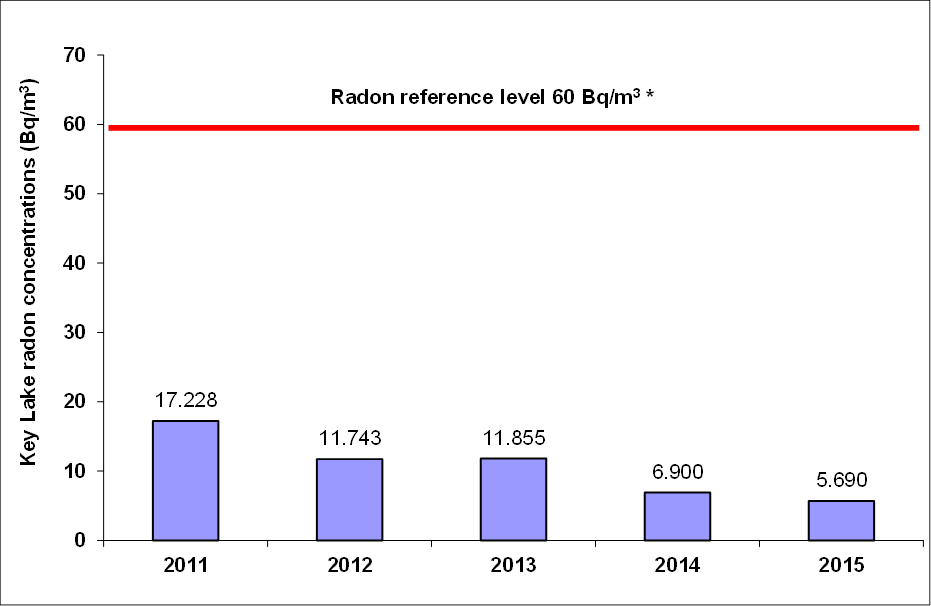

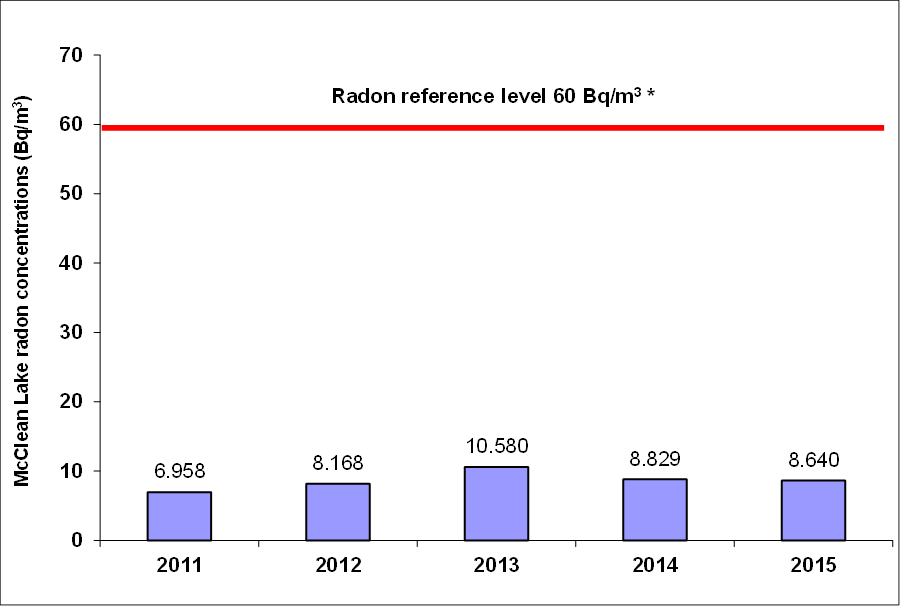

Environmental monitoring for radon concentrations is conducted using the passive method of track-etched cups. Eight monitoring stations are located in four quadrants around the immediate mine site. Figure 3.3 illustrates that the average concentrations of radon in ambient air for 2011 to 2015 were below the reference level for radon. The radon concentrations were also typical of the northern Saskatchewan regional baseline of < 7.4 Bq/m3 to 25 Bq/m3. As the Cigar Lake facility transitioned into operation, an increase was noted in the concentrations of radon in ambient air, as expected. Concentrations remained well below the reference level.

* The value of 60 Bq/m3 was derived from Publication 65 of the International Commission on Radiological Protection, Protection Against Radon-222 at Home and at Work,as referenced in the Radiation Protection Regulations. The reference level represents an incremental increase above natural dwelling radon levels that could result in a member of the public being exposed to an incremental dose of 1 mSv. Values are calculated as geometric means.

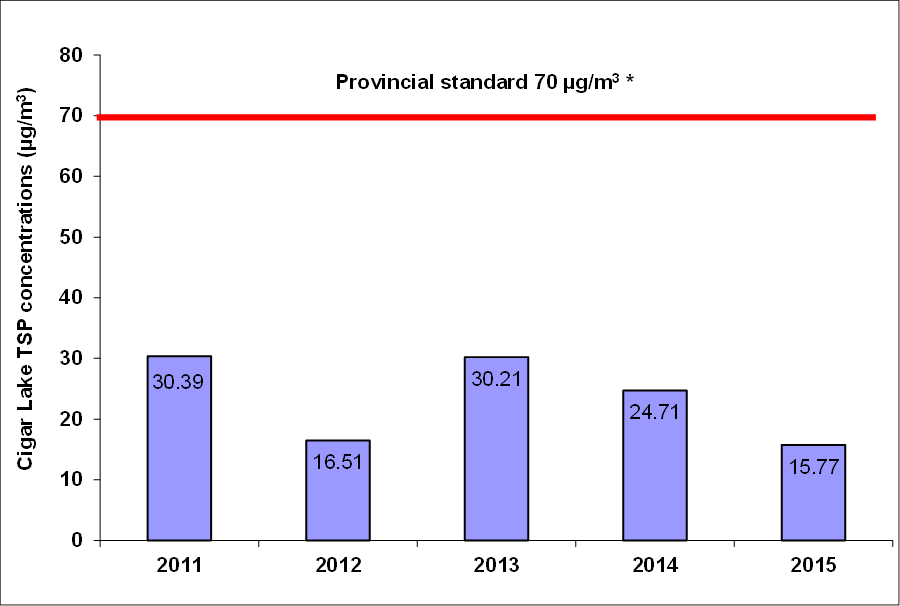

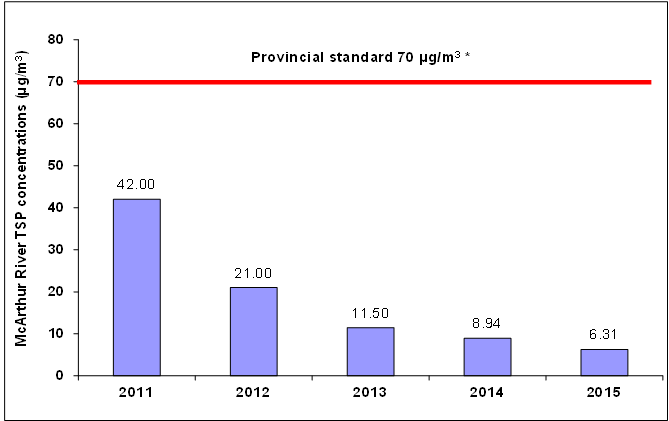

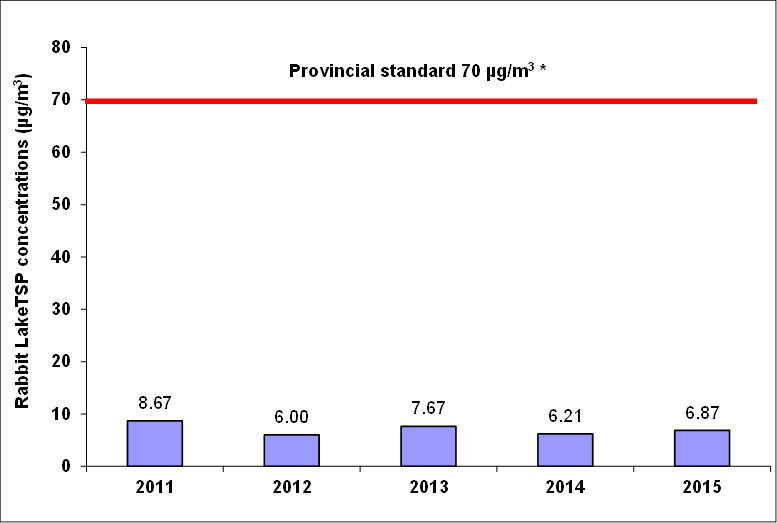

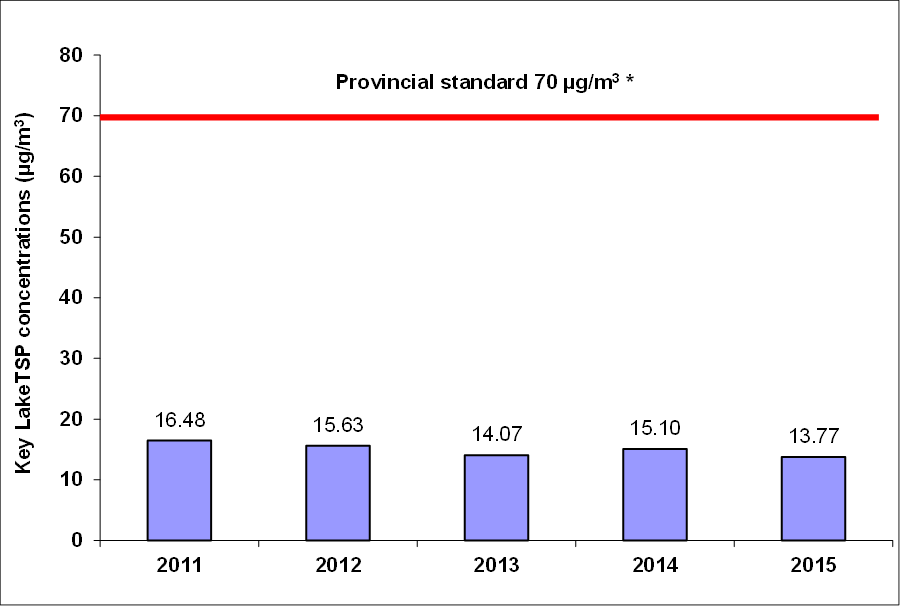

A high-volume air sampler (HVAS) was used to collect and measure TSP in air. The HVAS was located approximately 150 metres downwind from Headframe No.1 and the mine ventilation exhaust at the Cigar Lake operation. The TSP levels were below provincial standards (see figure 3.4). The mean concentrations of metal and radionuclides adsorbed to TSP were low and below the reference annual air-quality levels identified in table 3.2.

* The Province of Saskatchewan’s authorized concentration of contaminants monitored for ambient air quality as listed in the facility’s approval to operate pollutant control facilities is shown. The ambient air quality standards for TSP have been revised under the Saskatchewan Environmental Management and Protection Regulations and will be updated when the approval to operate document issued by the Province of Saskatchewan is renewed. Values are calculated as geometric means.

TSP samples are also analyzed for concentrations of metals and radionuclides.

| Parameter | Reference annual air quality levels | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|---|

| ||||||

| As (µg/m3) | 0.06 (2) | 0.00038 | 0.00025 | 0.00025 | 0.00025 | 0.00031 |

| Mo (µg/m3) | 23 (2) | 0.00021 | 0.00028 | 0.00021 | 0.0001 | 0.0001 |

| Ni (µg/m3) | 0.04 (2) | 0.00124 | 0.00101 | 0.00104 | 0.00067 | 0.00062 |

| Pb (µg/m3) | 0.10 (2) | 0.0018 | 0.0016 | 0.0007 | 0.0013 | 0.0009 |

| Se (µg/m3) | 1.9 (2) | 0.00005 | 0.00004 | 0.00003 | 0.00003 | 0.00003 |

| Pb210 (Bq/m3) | 0.021 (3) | 0.000333 | 0.000338 | 0.000268 | 0.00025 | 0.000315 |

| Po210 (Bq/m3) | 0.028 (3) | 0.000106 | 0.000106 | 0.000074 | 0.000086 | 0.000095 |

| Ra226 (Bq/m3) | 0.013 (3) | 0.000014 | 0.000005 | 0.000004 | 0.000008 | 0.000014 |

| Th230 (Bq/m3) | 0.0085 (3) | 0.000008 | 0.000026 | 0.000011 | 0.00001 | 0.000014 |

| U (µg/m3) | 0.06 (2) | 0.00012 | 0.00009 | 0.00007 | 0.00008 | 0.00055 |

Soil and terrestrial vegetation may be affected by atmospheric deposition of particulate and adsorbed metals and radionuclides associated with onsite activities. A terrestrial monitoring program is in place to determine if there is influence from aerial deposition. This program includes triennial measurements of metals and radionuclides in lichen and in soil. No lichen or soil samples were collected in 2015. The next sampling is scheduled to occur in 2016. Lichen and soil samples were collected in 2013, as required by the triennial sampling program. Sampling results are discussed in the 2013 regulatory oversight report. The 2013 data displayed that the concentrations of metals and radionuclides in lichen were similar to reference stations and historical data. CNSC staff concluded that the level of airborne particulate contaminants was acceptable and did not pose a risk to the lichen consumers such as caribou. The 2013 soil samples displayed that concentration of metals were below the levels described in the Canadian Soil Quality Guidelines for the Protection of Environmental and Human Health, and radionuclide concentrations were low and near, or at, background levels and analytical detection limits. CNSC staff concluded that the level of airborne particulate contaminants produced by the Cigar Lake operation is acceptable and does not pose a risk to the environment.

Environmental risk assessment

The CNSC uses environmental risk assessments to ensure that people and the environment are protected. The Cigar Lake Environmental Performance Report and updated Environmental Risk Assessment will be received in 2016.

Based on the information assessed, CNSC staff concluded that the environmental protection SCA at Cigar Lake met performance objectives and all applicable regulatory requirements.

3.4 Conventional health and safety

For 2015, CNSC staff continued to rate the conventional health and safety SCA as satisfactory.

| 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

Practices

CNSC staff monitored the implementation of the Cigar Lake operation’s safety and health management program to ensure the protection of workers. The program includes planned internal inspections, a safety permit system, occupational health committees, training and incident investigations. Cameco’s incident reporting system includes reporting, trending and investigation of near misses. This helps to reduce future incidents that could cause injury. CNSC staff verified the conventional health and safety work practices and conditions achieved an adequate degree of personnel safety at the Cigar Lake operation.

Performance

Table 3.3 summarizes LTIs at the Cigar Lake operation from 2011 to 2015. There were four LTIs at the Cigar Lake operation in 2015 and one reclassification of an event which occurred in 2014. Appendix H contains a brief description of these LTIs and the corrective actions taken by the licensee. CNSC staff assessed and were satisfied with the follow-up actions taken by the Cigar Lake operation.

| Year | 2011 | 2012 | 2013 | 2014 | 2015 | |

|---|---|---|---|---|---|---|

| ||||||

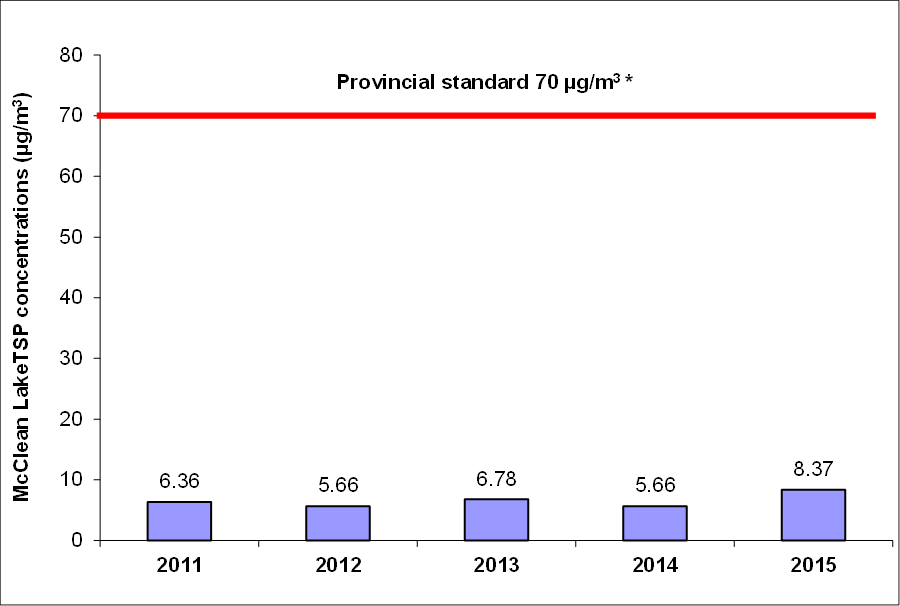

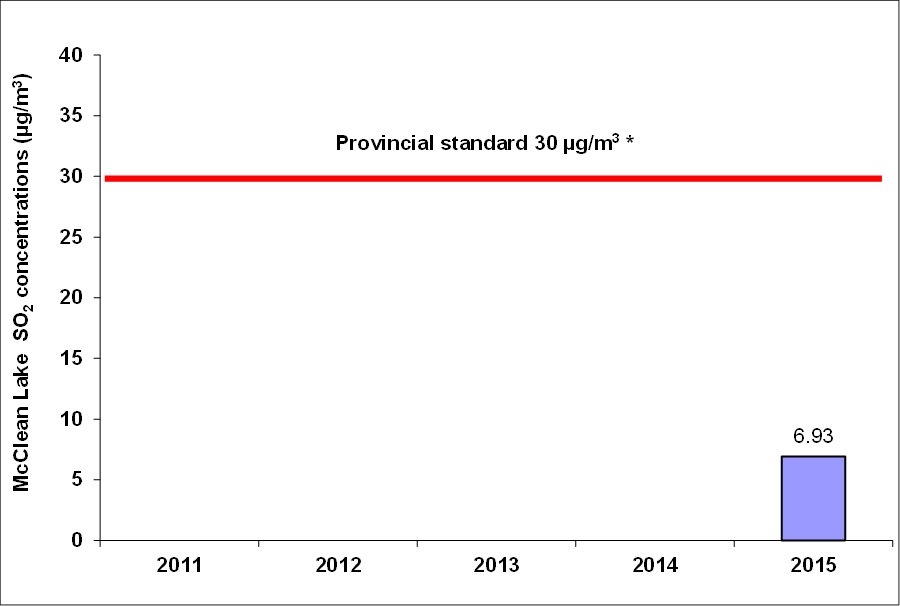

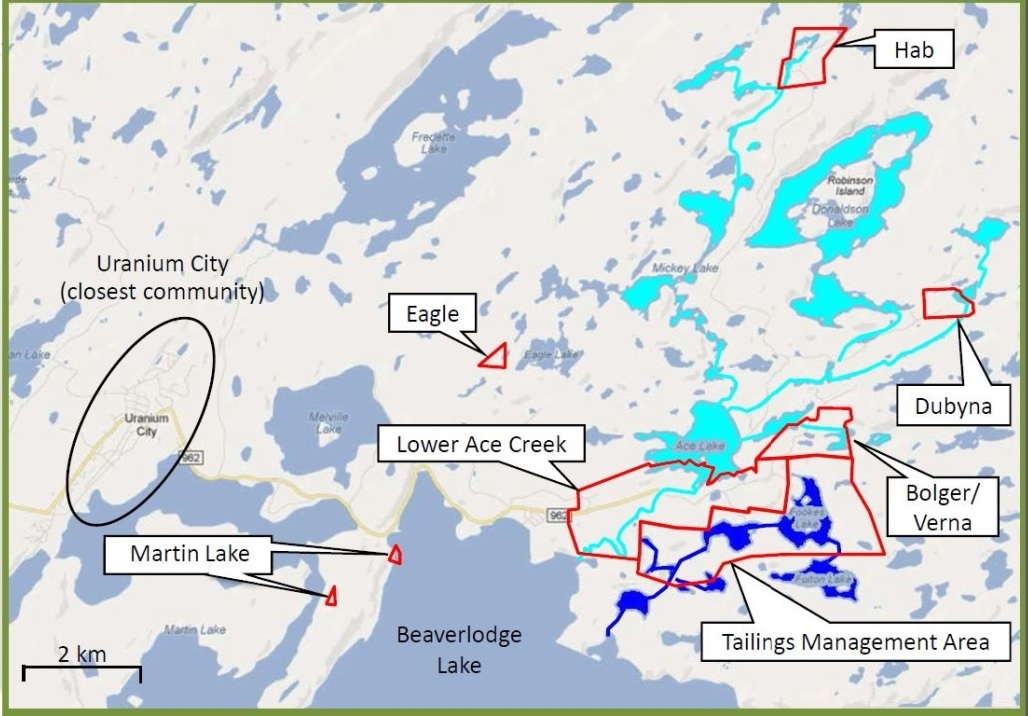

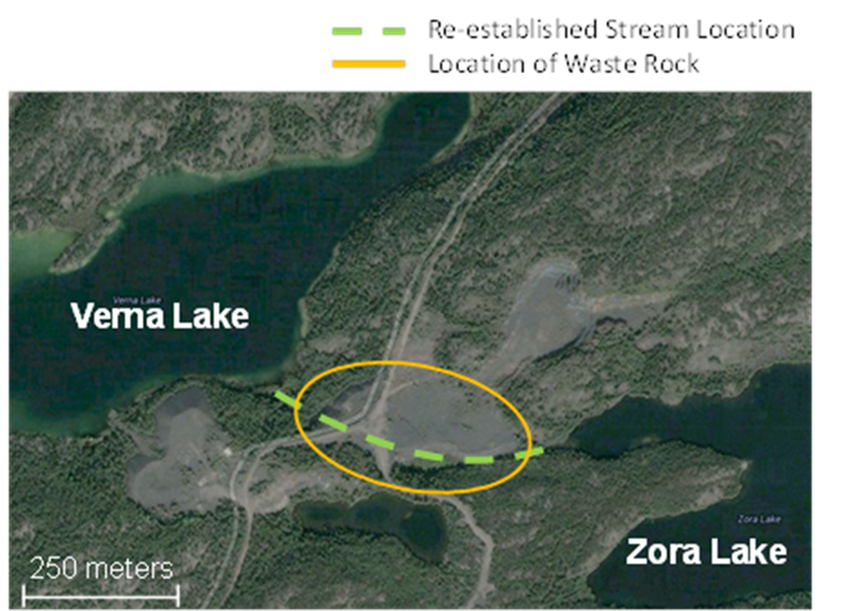

| Total number of FTE workers1 | 971 | 1,277 | 1,570 | 833 | 602 | |