Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2021

Table of contents

- Executive summary

- Use of nuclear substances in Canada: 2021

- Appendix A: Regulatory program for the use of nuclear substances

- Appendix B: Compliance performance

- Appendix C: Enforcement actions issued in 2021

- Appendix D: Doses to workers

- Appendix E: Reportable events

- Appendix F: Inspections conducted in 2021

- Appendix G: Stakeholder engagement activities in 2021

- Appendix H: Blank inspection worksheet

- Appendix I: Safety performance rating levels

- Appendix J: Relevant documents

Executive summary

The Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2021 provides information on the use of nuclear substances in the medical, industrial, academic and research, and commercial sectors. Licensees covered by this report are, for the most part, regulated by the CNSC’s Directorate of Nuclear Substance Regulation. The regulatory oversight report (ROR) also includes select waste nuclear substance licensees that are not reported on in other RORs and that are regulated by the Directorate of Nuclear Cycle and Facilities Regulation. Licensees covered by this report are located across Canada, and CNSC staff acknowledge all treaties and traditional territories on which the licensees that are subject to this report are situated.

The key message conveyed in this year’s ROR continues to be the impact of the COVID-19 pandemic on regulatory oversight, requiring the CNSC to balance the need for in-person compliance activities with the health and safety of the public and of CNSC and licensee staff. While 2021 allowed for the return of in-person inspections at a higher frequency than in 2020, the number of inspections conducted was still lower than in the years prior to the pandemic. Despite the reduced number of inspections, the indicators presented in this report demonstrate that the risks posed by the use of nuclear substances in Canada continue to be managed appropriately.

While overall compliance remains high, staff are beginning to see a moderate downward trend in some sectors for certain safety and control areas (SCAs). In particular, there was a decline in ratings this past year for the radiation protection SCA in the academic and research sector and for the security SCA in the medical sector. As explained in the 2020 ROR, CNSC staff had anticipated this decline given the restrictions on in-person inspections over the past 2 years. The link between inspections and this decline is twofold. First, inspections are a powerful tool for compliance promotion. Therefore, a lower frequency of inspections increases the probability of non-compliances by the licensee. Second, the nature of the CNSC’s risk-informed compliance program leads staff to focus their inspection effort on those licensees with the greatest potential for compliance problems, thereby introducing a bias in the performance results.

Based on their assessment of licensee performance results for 2021, CNSC staff continue to conclude that nuclear substances in Canada are used safely. However, staff will continue to monitor performance and will make it a priority to steadily increase their onsite presence. At the same time, the CNSC has a number of other ways to ensure safety across the regulated sectors, including a strong approach to licensing, the ability to react quickly to unforeseen events, and graduated enforcement tools that enable staff to bring a licensee back into compliance in cases of unacceptable performance. In addition, the CNSC’s risk-informed inspection planning process allows staff to target those licensees that are the highest priority, thereby ensuring that the CNSC’s inspector resources are applied with maximum effectiveness.

The CNSC’s annual RORs continue to evolve in response to feedback received from the Commission and from intervenors. As a result, staff have included 2 new sections in this year’s ROR: an explanation of the risk-informed planning process mentioned above, and an overview of how the CNSC assesses the environmental impact of nuclear substance licensees. In addition, a section has been reintroduced describing how the CNSC fulfills its international commitments for the 4 sectors covered in this report. This demonstration of responsiveness and transparency is a key element of the CNSC’s commitment to building trust in the nuclear regulator.

Based on the CNSC’s regulatory oversight, flexibility, and actions to respond to the changing work environment, the evaluations presented in this report confirm the following:

- The use of nuclear substances and prescribed equipment in Canada remains safe and secure.

- A rigorous process is in place to plan inspections on a priority basis.

- Thorough assessments of licensee applications ensure that licensees are compliant with regulatory requirements and understand their responsibilities.

- Doses to workers remain low and below prescribed limits.

- Non-compliances are addressed, and enforcement actions are closed in a timely manner.

- Events are reported and reviewed appropriately.

Overall, licensees made acceptable provisions to protect health, safety, security and the environment with respect to the use of nuclear substances and prescribed equipment, and took the measures required to implement Canada’s international obligations and commitments.

Use of nuclear substances in Canada: 2021

The Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2021 summarizes the safety performance of 1,500 licensees, which hold a total of 2,097 licences. The Canadian Nuclear Safety Commission (CNSC) authorizes licensees to use nuclear substances and prescribed equipment in the medical, industrial, academic and research, and commercial sectors. For a description of the licensed activities covered in this report, refer to the technical briefing to the Commission on nuclear substances in Canada (CMD 18-M49). This regulatory oversight report (ROR) also includes 5 waste nuclear substance licensees (WNSLs) that are not captured in any other CNSC ROR. They are included in the commercial sector throughout the report. Additional data on licensees covered by this ROR is available in appendix A.

CNSC staff use many metrics to evaluate licensees’ safety and security performance. This ROR uses a subset of those metrics, which, when taken together, provide a well-rounded picture of the performance of licensees. The metrics used in this report are:

Licensing oversight also plays a key role in supporting licensee performance. Rigorous assessments of licensee programs, along with timely desktop reviews of annual reports and changes submitted by the licensee, are critical in ensuring that licensees have appropriate programs and people in place to ensure the safe and secure use of nuclear substances in Canada.

In addition to the standard review of performance indicators, the 2021 ROR includes an overview of how inspection planning is used to mitigate the risk that has been introduced as a result of the decrease in inspections performed. This overview is presented in section 2.0.

In response to intervenor feedback, additional information has been included on inspection criteria (appendix H) and on environmental protection, as it relates to most licensees covered by this ROR (section 3.7). The section on international commitments and obligations has also been reintroduced in the report in response to feedback (section 8.0).

Lastly, the report provides the Commission with information about stakeholder engagement, which is a critical element of the CNSC’s regulatory approach. Given the breadth of licensees regulated in the area of nuclear substances, particular focus has been placed on reaching out to and engaging with licensee communities.

This ROR includes data in both the body and appendices. The main body of the report provides a high-level overview of the CNSC’s regulatory efforts and the licensees’ performance, while the detailed data to support this overview is found in the appendices.

1.0 Inspection overview in 2021

The COVID-19 pandemic continued to have an impact on regulatory oversight in 2021, requiring the CNSC to balance regulatory oversight with the health and safety of CNSC and licensee staff. Inspections in 2021 included a mix of remote, in-person and hybrid inspections depending on the restrictions in place at the time and the comfort level of staff in making an in-person visit to a licensee site. Until mid-2021, occupational health and safety protocols put in place in response to provincial and federal guidelines limited travel and in-person activities; however, when warranted by licensee performance, staff did perform in-person inspections. As restrictions started to ease and more routine, in-person inspections resumed in the summer, differing risk tolerances for travel and for in-person activities (for both the CNSC as a whole and for individual staff members) were key considerations when determining whether an inspection would be done in person or remotely. In fall 2021 (specific timelines dependent on location in Canada), the prevalence of new cases of the Omicron variant of COVID-19 across the country put a halt to routine onsite inspections once again.

In 2021, staff performed 583 inspections (233 in-person, 9 hybrid, and 341 remote). Most of these inspections were done in the industrial and medical sectors (63% and 27% respectively). This is to be expected as these 2 sectors make up approximately 79% of all licences and account for many of the licensed activities categorized as higher risk.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

The 583 inspections performed in 2021 exceeded the planned number of 495 inspections. It was also an increase over 2020, when only 371 inspections were performed (although it was still short of the number of annual baseline inspections conducted pre-pandemic). With the pandemic once again limiting onsite inspections, the use of remote inspections continued to be an essential component of regulatory oversight in 2021, with 60% of inspections being done remotely or in a hybrid manner. While remote inspections are a useful tool, CNSC staff believe that, in most cases, onsite inspections are the preferred option when possible; therefore, the proportion of onsite inspections is expected to increase as COVID restrictions continue to ease.

While the number of annual inspections has increased since 2020, CNSC staff can see a correlation between the reduced number of inspections due to the pandemic and the compliance results from the past 2 years (see section 3.0 for a discussion of compliance performance in 2021). The inspection planning process used by CNSC staff is designed to consider such changes in performance, using a risk-informed approach that prioritizes the most critical inspections. This planning process allows CNSC staff to maintain assurance that the nuclear substances sector continues to be safe despite the lower number of inspections (section 2.0 provides an overview of the CNSC’s inspection planning and prioritization process).

Notwithstanding these methods of mitigating the risk introduced by fewer inspections, CNSC staff will be working to increase the number of annual inspections in order to regain the baseline inspection frequency determined by the CNSC’s risk-informed compliance program. Primary responsibility for safety lies with the licensee; therefore, the CNSC expects licensees to comply with regulatory requirements whether they are subject to a CNSC inspection or not. Nonetheless, inspections are an important component of regulatory oversight that allow the CNSC to verify licensee compliance with those requirements. Moreover, they provide an opportunity for inspectors to intervene early with licensees when performance starts to decline, whether from complacency, lack of understanding of regulatory requirements, or poor safety culture. Inspections also provide a unique opportunity to gather certain types of performance information – inspectors can observe workers while they perform their duties to see if they are following procedures, and can get a sense of the overall effectiveness of a licensee’s safety culture and radiation protection program. This is especially true for licensees engaged in field work where it is important that workers follow procedures to ensure their safety, since physical barriers are not always available. CNSC staff can then use this information to make risk-informed licensing decisions.

Given the importance of inspections generally, and the priority given to addressing the current backlog, the availability of a sufficient number of trained inspectors is a key program constraint that CNSC staff are monitoring closely. To ensure that there are sufficient resources to conduct planned, baseline inspections, the CNSC aims to recruit enough new inspectors to compensate for natural attrition rates, and to retain the qualified staff already in place.

Lastly, while inspections are important, they are not the only regulatory oversight tool available to the CNSC to assess licensee compliance. Throughout 2021, CNSC staff also continued to review annual compliance reports submitted by licensees and monitor reported events. Both activities can provide indicators of licensee performance, which can supplement inspection findings. In addition, licensee programs are reviewed and evaluated as part of the licence assessments. High-quality assessments help ensure that licensees have strong programs in place.

Considering the full suite of compliance activities, as well as the ability to prioritize the most risk-significant inspections, CNSC staff have concluded that the impact on licensee performance from the continued reduced number of inspections in 2021 remains acceptable. As restrictions continue to be lifted, CNSC staff anticipate that the number of onsite inspections will increase, which will in turn lead to increased confidence that nuclear substance licensees continue to operate in a safe manner. Staff presence at licensee sites will be a reminder to licensees that regulatory oversight and compliance with regulatory requirements continue to be priorities for the CNSC.

2.0 Inspection planning overview

Across Canada, there are over 2,000 nuclear substance licences issued by the CNSC and over 3,000 locations subject to CNSC inspections (since licensees can have more than one location). Given this high volume of licences and the finite number of inspectors, the Directorate of Nuclear Substance Regulation (DNSR) needs to deploy its resources to ensure maximum effectiveness. This is done through the application of a risk-informed inspection planning process, where resources and regulatory oversight are applied commensurate with the risk posed by the regulated activities.

The DNSR inspection planning process involves many considerations. First, risk rankings are established for each type of licensed activity, which provides a relative order of regulatory effort (in the areas of both licensing and compliance) to be applied to that activity. This risk ranking is the primary driver for setting a baseline inspection frequency for a specific facility or activity. The baseline is defined based on a well-performing licensee who meets all regulatory requirements in a particular area and is determined by CNSC staff using the risk index approach in accordance with CAN/CSA-IEC/ ISO 31010-10, Risk Management – Risk Assessment Techniques. Experience has demonstrated that not all licensees within a particular subsector require the same inspection frequency.

With this initial baseline established, staff prioritize inspections on a yearly basis using a risk-informed approach that takes into account specific criteria. The prioritization exercise may consider any or all of the following criteria:

- licensees most overdue for inspection

- new licensees (never inspected, potential unknown risks)

- compliance/performance history at the licensee level, including enforcement actions

- sector and/or subsector performance trends

- instigating factors (e.g., changes in radiation safety officers, amalgamation of licences, acquisitions, mergers and licence transfers)

- staff input based on knowledge of a particular licensee

- list of licensees or locations that require a follow-up inspection

The prioritization process considers all licensees that are due for an inspection according to the baseline. The process then involves assessing the risk profile of the licensees according to the frequency, recurrence and severity of past non-compliances; reviewing performance and compliance trends; and creating the priority lists based on defined criteria.

The priorities are separated into 3 categories:

- Priority 1 (P1) inspections must be performed as assigned, or declined with a defensible and documented rationale (i.e., decommissioned location, inaccessible, inventory not present).

- Priority 2 (P2) inspections, while not required to be performed, should be prioritized above all other remaining options.

- Priority 3 (P3) inspections are the remainder of the inspections that are due and can be performed after P1 and P2 inspections have been considered.

The prioritization of inspections into 3 categories helps ensure that staff are inspecting licensees and locations where the need is greatest. It allows flexibility to be built into the plan. The execution of the inspection plan is then dependent on available resources and on restrictions (e.g., travel constraints during the pandemic). It is also dependent on unplanned work that must be addressed. For example, approximately 30% of compliance effort is spent on reactive work related to the follow-up of non-compliances by licensees or to verify licensee response to events. The amount of effort expended on these activities will vary depending on the performance of licensees and on the number of events reported that require follow-up.

Overall, the inspection planning process is effective at ensuring that resources are applied appropriately for compliance oversight purposes. In light of the restrictions imposed by the pandemic, this established process allowed the CNSC to accommodate a reduction in annual inspections without compromising safety, by concentrating its resources on those highest priority inspections.

3.0 Compliance performance

Appendix B covers the full 2021 performance data, broken down by SCA, sector and subsector. In addition, the data shows the 5-year performance trends within each of these categories.

Overview of compliance framework

To measure licensee performance, CNSC staff use the well-established Safety and Control Area Framework. The framework includes 14 safety and control areas (SCAs) covering all technical areas of regulatory oversight. While CNSC staff review and assess performance in all SCAs (if applicable) as part of licensing and compliance activities, the ROR focuses on those that are most effective in providing an overall indication of the safety performance of the licensees, namely, the management system, operating performance, radiation protection, and security SCAs. Performance data in the environmental protection and the conventional health and safety SCAs is also provided for the waste nuclear substance licensees. These licensees, unlike other licensees covered by this report, have a higher potential for environmental releases. In addition, given the nature of the work performed and the introduction of other hazards to be mitigated, there is a potentially higher risk in conventional health and safety.

During licensing and compliance activities, CNSC staff evaluate the licensee’s performance within each relevant SCA by reviewing licensee documents and conducting inspections. Owing to the broad nature of the different activities conducted by the licensees covered, not all SCAs apply to all activities or all licensees. All relevant SCAs are assessed during inspections and a compliance rating is assigned for each one. Individual SCAs may include multiple assessment areas. The areas or items to be assessed arise from regulatory requirements, licence conditions, and documents referenced in the licence. Some of these requirements are administrative in nature and are considered relatively low risk, while others are linked to an immediate risk to health, safety or security, and therefore any findings against these items during an inspection must be addressed immediately. Refer to appendix H for an inspection worksheet template used for a typical inspection of nuclear substances and radiation devices licensees, specifically those in the portable gauge subsector. All areas assessed within a given SCA impact the overall rating of that SCA. A description of the ratings is provided in appendix I. The ratings definitions were updated in 2021 to improve clarity. CNSC staff presented the updated definitions and provided an explanation of the revisions to the Commission in January 2022 as part of the Update on the CNSC Staff Review of the Regulatory Oversight Report Process presentation.

CNSC staff track and follow up on all required corrective actions arising from less than satisfactory performance (“below expectations” or “unacceptable” ratings) to ensure that all items of non-compliance are addressed to their satisfaction. In the event an immediate risk to health, safety or security is identified, CNSC staff take prompt action, which may include enforcement actions such as the issuance of orders. Administrative monetary penalties (AMPs) may also be used as part of a graduated approach to compliance for issues that do not pose an immediate risk to health or safety.

Feedback from stakeholders: Additional information on SCAs in the 2021 ROR

CNSC staff acknowledge that all SCAs are important, regardless of whether they are included in the ROR. Based on interventions in previous ROR proceedings and on follow-up discussions with intervenors, the packaging and transport and the environmental protection SCAs continue to be the areas where stakeholder interest is high.

The interest in packaging and transport is not surprising given the volume of shipments of nuclear substances made each year. However, the packaging and transport SCA is not applied in the same manner across all licensees and depends on the nature of the industry. For example, the packaging and transport SCA is of high importance in the portable gauge or industrial radiography subsectors as these are mobile radiation devices that are transported daily. In comparison, within the fixed gauge subsector, the packaging and transport SCA is of minimal importance as these radiation devices are generally in a fixed place for lengthy periods of time and might only be packaged for transport at the beginning and the end of their life. Comparing data for these different subsectors becomes difficult as the activities performed are varied, and it would be challenging to present performance data in a meaningful way in the ROR. Instead, a review of the reported events related to packaging and transport provides a more meaningful indicator for this SCA across the sectors. As was done as part of the 2020 ROR, further analysis of this indicator is provided in appendix E.

With regard to the environmental protection SCA, much of the stakeholder interest is related to how REGDOC-2.9.1, Environmental Principles, Assessments and Protection Measures, applies to the licensees covered by this report. Environmental protection is considered as part of all licence application assessments and as part of compliance oversight. For some licensed activities where there are no interactions with or releases to the environment, no additional environmental protection measures are required. For all other licensed activities, REGDOC 2.9.1 is applied in a graded manner. In response to interest in this area, CNSC staff have included additional information on this topic in section 3.7.

Overall analysis of 2021 compliance results

A total of 5 unacceptable ratings, as defined by the CNSC, were issued in 2021. All 5 were issued to the industrial sector and all were issued in the SCAs covered by this report, as described in the sections below. CNSC staff issued orders in 3 of the 5 instances and took licensing action in the other 2. No unacceptable ratings were issued in the SCAs not covered in this report.

A list of inspections performed in 2021 is available in appendix F. Where items of non-compliance were identified, CNSC staff verified that licensees took appropriate corrective actions. Licensees promptly addressed any items of non-compliance that had immediate risks to health, safety or security.

Overall licensee performance in the 4 sectors (medical, industrial, academic and research, and commercial) has remained satisfactory and relatively stable over the past 5 years in all SCAs covered by this report; however, there was more significant variation at the subsector level, as described below. This decline in performance in certain areas was not surprising and, in fact, was predicted in the 2020 edition of the ROR on the use of nuclear substances in Canada. While a number of factors influence compliance, CNSC staff believe that there is a link between the decline in performance and the reduced number of inspections in recent years, as described in section 1.0. In addition, downward trends in compliance over the past year could reasonably be attributed to other influences, including the typical adjustment period that follows the introduction of new regulatory requirements (notably for the radiation protection SCA, as described below), as well as the impact of the pandemic on licensee operations, particularly in the medical sector. Lastly, it is always important to keep in mind that, for some sectors, overall performance in a given SCA is extrapolated based on very small datasets, which limits the reliability of any conclusions drawn.

Regardless of the reasons for the declining performance, CNSC staff continue to monitor compliance results and use those results as one of the inputs for the risk-informed approach to regulating these sectors. In addition, the CNSC maintains the capacity to respond quickly to an event and, as already mentioned, ensures that licensees promptly address any risk-significant areas of non-compliance.

While not showing a particular decline this past year, the 2021 performance results in certain SCAs for some sectors continued a trend of slightly poorer performance over the last 5 years. In particular, this applies to the radiation protection SCA in the medical sector and the operating performance SCA in the fixed gauge subsector. Although the majority of licensees consistently achieve satisfactory ratings in these SCAs, CNSC staff have developed and implemented various strategies in recent years to promote increased compliance. While, admittedly, more work needs to be done in these sectors, the CNSC’s current focus on regaining the baseline inspection frequency means that it is not actively developing new regulatory responses at present. Until that baseline has been regained, CNSC staff will continue to closely monitor compliance indicators in these areas and will maintain the capacity to address any serious concerns in an expedited manner.

When reviewing the compliance results for 2021, it is important to put them in context: while they represent a key indicator of licensee performance, they are not the only one used. In addition to analyzing compliance data, CNSC staff also make use of other indicators, including those reported on in this ROR, in assessing risk and making decisions about how to implement our regulatory oversight.

A brief overview of the SCAs is provided below, with more details provided in appendix B. Appendix B.5 presents the inspection results by subsector, offering another perspective on licensee performance in 2021.

3.1 Management system

The management system SCA covers the framework that establishes the processes and programs required to ensure that an organization achieves its safety objectives, continuously monitors its performance against those objectives, and fosters a healthy safety culture.

In 2021, all sectors performed well in this SCA, with 97% of inspections receiving satisfactory ratings. This is comparable to previous years. There were no unacceptable ratings in this SCA.

Refer to appendix B.1 for additional information.

3.2 Operating performance

The operating performance SCA refers to the licensee’s ability to perform licensed activities in accordance with pertinent operational and safety requirements defined in the Nuclear Safety and Control Act (NSCA), its associated regulations, and licence conditions. Licensees are expected to demonstrate that they comply with operational and safety requirements by providing workers with appropriate procedures for the safe use of nuclear substances and prescribed equipment, by ensuring that workers follow procedures, and by maintaining records that demonstrate compliance.

In 2021, overall licensee performance in this SCA improved, with 87% of inspections yielding satisfactory ratings compared to 83% in 2020. Performance increased in all sectors except the commercial sector, where the percentage of inspections yielding satisfactory ratings in this SCA decreased by 7 percentage points compared to 2020.

One licensee in the industrial sector received an unacceptable rating in this SCA. As a note, the same licensee was issued an unacceptable rating in the security SCA. In response to these poor ratings, the CNSC issued order 1340 to the licensee. The licensee complied with all terms of the order to the satisfaction of the CNSC and the order is now closed.

Refer to appendix B.2 for additional information.

3.3 Radiation protection

Radiation protection programs are required for every licensee to ensure that contamination levels and radiation doses received by workers are monitored, controlled, maintained below regulatory dose limits, and kept at levels that are as low as reasonably achievable (ALARA), with social and economic factors being taken into account. Licensees are expected to monitor worker doses, post radiation warning signs, plan appropriately for radiological emergencies, manage oversight of operational activities, institute effective workplace practices that emphasize the use of time, distance and shielding to minimize exposure to radiation, and use appropriate protective equipment.

Overall, in 2021, licensees maintained similar ratings compared to previous years, with 83% of inspections resulting in satisfactory ratings in the radiation protection SCA. While the medical and industrial sector ratings were similar to previous years, both the academic and research sector and the commercial sector demonstrated a decline in performance. In particular, the academic and research sector showed a significant decline in performance, with only 78% of 23 inspections performed yielding a satisfactory rating in the radiation protection SCA in 2021 compared to 100% of the 10 inspections performed in 2020. As noted earlier, these performance results are an indicator that CNSC staff factor into their inspection planning. However, while 5 of the 23 inspections performed received a below expectations rating in 2021, it represents only a small proportion of the 187 licences in the sector, making it difficult to confirm whether this is representative of the entire sector.

The revised Radiation Protection Regulations came into effect in late 2020. Part of the regulatory oversight program involved having inspectors promote compliance with the amended regulations while performing compliance activities. As of mid-2021, all licensees were expected to have implemented all changes related to the amended regulations. It is therefore reasonable to conclude that this is another reason for declining performance, as licensees adjust to the new requirements. Notices of non-compliance were issued in cases where it was found that licensees had not updated their programs to align with the amended regulations.

There were 3 unacceptable ratings issued in the radiation protection SCA in 2021. All 3 were issued in the industrial sector. In one case, an order was issued (order 1223) to an industrial radiography licensee in response to this rating. The licensee complied with all terms of the order to the satisfaction of the CNSC and the order is now closed.

In the second case, the licensee agreed to put all its portable gauges in storage and requested an amendment to its licence to reflect this change until a new radiation safety officer is in place and its radiation protection program is adequately implemented. As of the writing of this report, all portable gauges remain in storage.

The last unacceptable rating in this SCA was issued to a fixed gauge licensee. It was determined that there had been a significant failure by the licensee to implement its radiation protection program and that there was a lack of management oversight of the licensed activities. The licensee was intending to request the revocation of its licence and had transferred 4 of its 5 fixed gauges for disposal just prior to the inspection. However, one of the gauges (a low risk, category 4 sealed source) that had been in storage was lost (event ID 5357) and has not been found as of the writing of this report. The licence was revoked in May 2022; however, the licensee has committed to continuing the search and has a plan in place for if and when it is found. This plan includes immediately notifying the CNSC if the gauge is found and arranging for its disposal, including covering the costs.

Refer to appendix B.3 for additional information.

3.4 Security

Licensees are required to have in place physical security measures, practices and programs to prevent the loss, illegal use, illegal possession or illegal removal of nuclear substances during their entire lifecycle, including while they are in storage or during transport, as per the NSCA. The extent of the security measures required depends on the types of nuclear substances used and activities performed by each licensee.

In 2021, nuclear substance licensees maintained strong compliance with applicable security requirements, including the general requirements contained in regulations and in REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources and Category I, II and III Nuclear Material, applicable to sealed sources and radiation devices. Consistent with previous years, 91% of licensees inspected received a satisfactory grade in this SCA.

However, the medical sector demonstrated a drop in performance, with only 79% of the 34 inspections receiving a satisfactory grade in 2021 compared to 97% of the 33 inspections performed in 2020. In this sector, it is important to note that only 7 inspected licences (of the 440 medical sector licences) received a below expectations rating; therefore, the data may not be sufficient to conclude that there has been an overall decrease in performance for the whole sector. Furthermore, the projected link between a reduction in inspections and a decline in licensee performance is particularly relevant for the security SCA, since certain elements of security inspections cannot be performed remotely.

There was also a significant increase in the number of security-related events reported in 2021(more than double the average of the previous 4 years), with over 40% reported in the medical sector. The actual risk presented by these security breaches was low, and no nuclear substances were lost as a result of any of the events. This is further discussed in section 6.0.

As mentioned earlier, one licensee in the industrial sector received an unacceptable rating in both the security SCA and the operating performance SCA. In response to these poor ratings, order 1340 was issued to the licensee and is now closed.

Refer to appendix B.4 for additional information.

3.5 Conventional health and safety for waste nuclear substance licensees

The CNSC requires WNSLs to have a program in place to manage workplace safety hazards and to protect workers given the nature of the work and the introduction of other hazards that need to be mitigated. For example, WNSLs handle, process, store and transport different types of radioactive waste, which may require the use of overhead cranes and large equipment. The licensed activities directly introduce mechanical, ergonomic, chemical, electrical and fire hazards that need to be mitigated.

In 2021, no WNSLs received below expectations or unacceptable ratings in the conventional health and safety SCA.

The licensees continued to implement health and safety programs in accordance with the applicable occupational health and safety legislation to protect the health and safety of their workers.

3.6 Environmental protection for waste nuclear substance licensees

WNSLs are required to have specific programs in place to identify, control and monitor all releases of radioactive and hazardous substances and their effects on the environment.

In 2021, no WNSLs received below expectations or unacceptable ratings in the environmental protection SCA. The WNSLs continued to manage and monitor environmental releases relating to licensed activities.

WNSLs reported 3 events that could potentially have impacted the environment in 2021.

In the first event, the licensee reported that a holding tank of water from laundry was inadvertently discharged to the sewer. The intent was to transfer the water to a different tank, but the operator missed that the drain valve to the sewer was open. The water had been sampled beforehand, and results indicated that radiological parameters were all well below derived release limits and action levels. However, the concentrations of total suspended solids, total phosphorous (non-radioactive) and biological oxygen demand exceeded the municipality’s by-law limits. The municipality confirmed that there were no adverse conditions detected in the municipal sewage treatment plant as a result of the discharge.

In the second reported event, consolidated plant wastewater streams were discharged from a holding tank with the appropriate approvals as specified by procedures. A consolidated sample was preserved and subsequently analyzed, and the total non-radioactive phosphorous concentration indicated that there was a minor exceedance of 0.75 ppm over the limit (limit is 10 mg/L). Prior to the transfer to the holding tank, a separate analysis of the waste streams indicated that the consolidated liquid would be below the limit. The licensee believes there was an issue related to recirculation in the holding tank, resulting in a non-homogeneous sample being tested. There was no requirement to immediately notify the municipality, and it was reported in the licensee’s quarterly report submission to the municipality. There were no adverse environmental effects.

Lastly, one licensee reported that it had been sampling local air and not the air released from the stacks for a period of a few weeks to a month due to equipment failures. No work with potential for high levels of airborne tritium was conducted in the area that the stack in question serves. Based on the work performed during that period, an estimated 2 GBq/week of tritium was emitted from the stack, which is well below the action level, and there was no work conducted in this period that could have produced higher results. All other parameters, both radiological and non-radiological, were below the relevant limits and action levels.

All releases were kept well below regulatory limits, and there was no impact on the health and safety of persons and the environment.

3.7 Environmental protection for other nuclear substance licensees

Performance results in the environmental protection SCA for nuclear substance licensees are not typically included in the ROR, since those licensees have minimal to no interactions with the environment. In response to questions raised by intervenors on previous RORs, CNSC staff are providing a more fulsome explanation of the rationale for excluding this SCA from the report.

CNSC staff apply REGDOC-2.9.1, Environmental Principles, Assessments and Protection Measures, when reviewing applications for nuclear substance licences to ensure that there are no significant interactions with the environment. These licences generally cover activities involving the use of sealed or unsealed sources.

For sealed sources (e.g., fixed or portable gauges used in the industrial sector that contain sealed sources), the analysis performed led staff to conclude that there are no routine interactions with the environment and that, therefore, there is no need for an environmental risk assessment and little to assess under the environmental protection SCA.

For unsealed sources (e.g., radioisotopes used in the medical sector), there is a higher chance of interaction with the environment. This could involve, for example, releases from the stacks of isotope processing facilities or the disposal of small amounts of medical isotopes to the landfill or the sewer. For these licensees, CNSC staff apply the requirements in REGDOC-2.9.1, Environmental Principles, Assessments and Protection Measures, in a graded manner. Additional information on the application of REGDOC-2.9.1 to the nuclear substance licensees covered in this ROR is summarized below and will be covered in the proposed draft REGDOC 2.9.2, Controlling Releases to the Environment, which is currently under development and is scheduled to be presented to the Commission in September 2022.

In general, for licences authorizing the use of unsealed nuclear substances, the following apply with respect to disposal or releases:

- standard exemption quantity (EQ) and unconditional clearance levels specified in Schedules 1 and 2, respectively, of the Nuclear Substances and Radiation Devices Regulations

- generic conditional clearance levels (CCLs) documented in REGDOC 2.9.2, Controlling Releases to the Environment, provided that releases occur only through the specified pathway (i.e., solids to municipal landfill, gases to atmosphere, liquid to municipal sewer)

- practice-specific conditional clearances, which are CCLs applicable only to a defined practice or activity and which have been developed by the CNSC for application to multiple licensees carrying out the specific practice or activity; they are generally included as a condition on a licence

The majority of licensees covered by this ROR do not use unsealed sources as part of their licensed activities. Therefore, reporting on this SCA would not be effective in providing an overall indication of the safety performance of the licensees covered by this report. Licensees must, however, have programs in place to ensure that they meet any release limits imposed on them, and program implementation is verified during inspections and desktop reviews.

CNSC staff conclude that the oversight of the environmental protection SCA for nuclear substance licensees and the assessment and controls put in place for environmental protection for the industry are such that there is no additional benefit to highlighting performance in this SCA for all licensees covered in this report.

4.0 Enforcement

Appendix C presents enforcement action data by sector over the past 5 years and includes a list of all orders and AMPs issued in 2021.

The CNSC uses a graduated approach to enforcement in order to encourage compliance. When non-compliance (or continued non-compliance) has been identified, CNSC staff assess the significance of the non-compliance and determine the appropriate enforcement action, including but not limited to orders and administrative monetary penalties (AMPs).

In 2021, CNSC staff issued 10 orders and 1 AMP. All enforcement actions were issued to licensees in the industrial sector, with the exception of 1 order that was issued to a non-licensee in possession of radiation devices without a licence authorizing such possession. The fact that all but 1 enforcement actions were issued in the industrial sector is consistent with trends from previous years.

As expected, since enforcement actions tend to be issued as a result of findings during inspections, the number of enforcement actions issued in 2021 was higher than the number issued in 2020, given that the number of inspections performed also increased. Although neither the number of inspections nor the number of enforcement actions have reached pre-pandemic levels, staff anticipate that as the inspection numbers increase moving forward, the number of enforcement actions will also increase. All enforcement actions issued in 2021 are closed, and the CNSC is satisfied that the licensees and the 1 non-licensee have addressed the conditions of the orders/AMPs.

Enforcement actions are posted on the CNSC regulatory actions web page as they are issued.

5.0 Effective doses to workers

Appendix D presents the full datasets, as well as additional information, on effective doses to workers in 2021

Licensees are required to keep radiation doses to persons below regulatory limits and as low as reasonably achievable (ALARA) in accordance with the radiation protection program referenced in their licence.

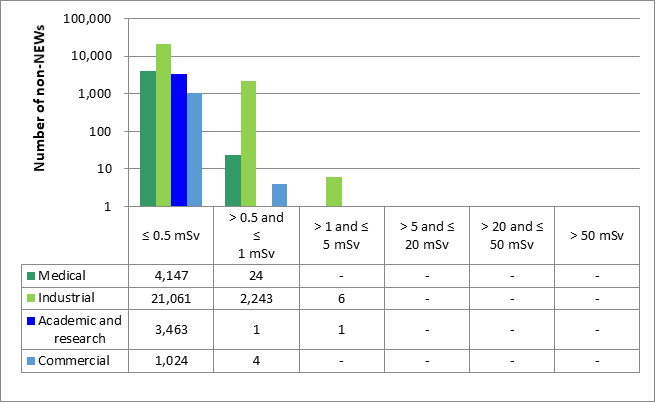

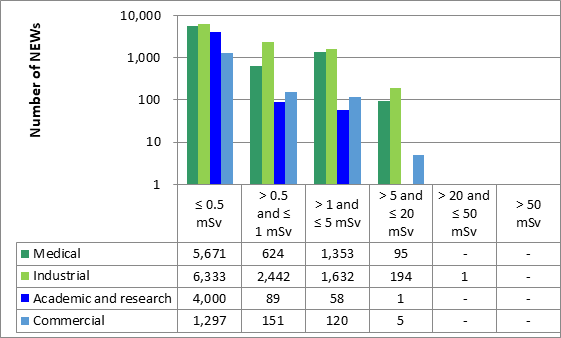

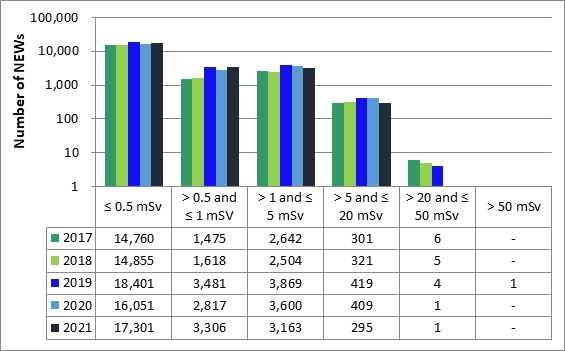

Licensees must report the doses to their workers, whether estimated or measured, as part of their annual compliance reports. In 2021, doses were reported for 56,040 workers in the 4 sectors. Of those workers, 24,066 were nuclear energy workers (NEWs). The remaining 31,974 were not identified as NEWs and are referred to as non-NEWs in this report. Exposures to radiation continued to be very low for workers covered in this ROR for 2021, consistent with previous reporting years.

In 2021, no NEWs received doses above the regulatory limit of 50 mSv per calendar year. Of the 31,974 non-NEWs for which doses were reported, there were 7 reported doses greater than the regulatory limit of 1 mSv/year.

In one case, a portable gauge licensee reported that a seasonal worker had received a dose of 3.82 mSv. Based on the work performed by the worker, the dose was deemed non-personal and likely resulted from improper storage of the dosimeter. The licensee began the process for a dose change request, but was not able to reach the worker to have him sign it as he was out of the country. The licensee subsequently received an email resignation from the employee. The licensee tried again to reach him but was unsuccessful; therefore, the dose change request will not proceed.

Five of the doses that were reported as being above the 1 mSv/year limit for non-NEWs involved 2 licensees who did not correctly identify workers likely to exceed the regulatory limit. All 5 of the non-NEWs worked in the portable gauge subsector (2 for one licensee and 3 for another). Their doses were estimated based on the number of “shots” using a portable gauge. One shot is equal to approximately 1.2 mSv. The maximum number of shots by any of these workers was 1,962, which would be the equivalent of approximately 2.4 mSv. In all 5 cases, the workers left their employment before they could be acknowledged as NEWs. In these cases, it was the licensees that failed to correctly assess the work to be performed by their workers, identify those workers likely to exceed the 1 mSv dose limit, and acknowledge them as NEWs. CNSC staff consider this to be an administrative non-compliance.

Lastly, in one case, a worker in the academic and research sector received a dose of 1.3 mSv. The licensee investigated the dose and concluded that the worker did not follow established safe work practices, leading to the elevated dose. The licensee reviewed all its workers' doses for the past 5 years and confirmed that all laboratory personnel are typically well below 0.2 mSv. The licensee implemented corrective actions to prevent recurrence. This event was presented to the Commission as an event initial report (EIR) on January 21, 2021 (CMD 21-M10).

There was strong performance in the industry in 2021, with doses to all workers remaining generally low. Of the 7 reported instances where a worker not designated as a NEW exceeded the regulatory limit, only 1 was deemed as a true exceedance of the regulatory limits; no health effects are expected in that case.

6.0 Reportable events

Appendix E provides data on the types of events reported over 5 years and describes each event reported in 2021.

Licensees are required to have programs in place to manage unplanned events and accidents. The events that warrant mandatory reporting and the content of those reports are set out in the NSCA, its regulations and the licence conditions. CNSC staff review, assess and track all events reported by licensees.

Since 2014, reported events have been rated using the International Nuclear and Radiological Event Scale (INES), a 7-point scale for communicating the safety significance of nuclear and radiological events to the public. Note that the scale is not a tool for comparing safety performance among facilities or organizations, but rather, for effectively communicating the safety significance of events. CNSC staff assign a ranking to each event based on the INES scale.

The events reported to the CNSC by the licensees covered in this ROR typically fall into level 0 (no safety significance), 1 (an anomaly that may have an impact on defence in depth) or 2 (incident that may have more significant impacts on defence in depth, impacts on people or the environment, or impacts on radiological barriers and controls).

CNSC staff assessed 171 events related to nuclear substances and prescribed equipment in 2021. Of these events, 165 were rated as INES level 0, and 6 as INES level 1. Of those rated as INES level 1, 5 involved the theft of portable gauges and 1 involved the loss of a fixed gauge. All 6 events involved category-4 sealed sources (i.e., low risk). Of the 5 stolen portable gauges, 2 were recovered and returned to the owner, while the other 3 have not yet been recovered. The lost fixed gauge has not been found.

While the 171 events reported in 2021 represent an increase in comparison to the 135 reported in 2020, the number is more consistent with the years preceding 2020. In 2020, the numbers reported were likely lower due to initial lockdowns and/or licensee restrictions on their operations during the initial stages of the pandemic. Although lockdowns related to the pandemic occurred in 2021 as well, most licensees maintained normal or near normal operations, meaning that the number of events reported also returned to more normal levels.

Overall, the most significant change in the types of events reported was in the area of security events. Significantly more breaches of security were reported in 2021 compared to the previous 4 years, as seen in Appendix E, figure 18. Over 40% of the reported breaches of security were in the medical sector, with most of those reports involving unattended nuclear substances, unsecured doors, or disarmed alarm systems. As mentioned previously, medical sector licensees experienced significant impacts due to the pandemic that may have led to changes in staffing, day-to-day operations and overall workflow, any of which could have resulted in an increase in events. One medical sector licensee in particular reported multiple events. The licensee launched a review of its security program, and CNSC staff have a strategy in place to manage this particular licensee, including a focused security inspection in 2022. It is important to note that while the numbers trended upwards in 2021, the actual risk presented by these events was low and no nuclear substances were lost as a result of any of the events. Licensees employ multi-layered security programs. The failure of one or two barriers did not lead to the breakdown of other barriers, which remained intact until the incidents were discovered and corrective action was taken.

There was also an increase in the number of spill, contamination and release events reported in 2021 compared to previous years. Over 60% of these were reported by the nuclear medicine subsector and involved spills or contamination with short-lived radioisotopes. None of the 26 events reported resulted in impacts to the environment. Although none of the events resulted in any exposures above the regulatory limit and all were rated as INES level 0, a significant event was reported by a licensee in the commercial sector that led to an unplanned exposure to a NEW. A spill of greater than 100 EQ of iodine-131 occurred in a radiation-shielded box, under a vented hood. The subsequent clean-up resulted in an unplanned exposure to a NEW of 29 mSv (effective dose) and a committed equivalent dose to the thyroid of 560 mSv, both of which are below regulatory limits. The unplanned dose was determined to be a result of a gap in licensee procedures and a failure of the worker to follow thyroid monitoring procedures. The licensee has taken appropriate corrective measures to address these issues and the CNSC has shared lessons learned with other similar licensees. A verbal EIR was presented to the Commission in April 2021, with subsequent follow ups in October 2021 and March 2022.

For all events reported to the CNSC, licensees implemented appropriate response measures to mitigate the impacts and to limit radiation exposure to workers and the public. CNSC staff reviewed the measures and found them to be satisfactory.

6.1 Update on Mississauga Metals & Alloys Inc.

In the first quarter of 2021, Mississauga Metals & Alloys, Inc. (MMA), one of the 5 waste nuclear substance licensees (WNSLs) covered by this ROR, applied for and received a short-term renewal of its waste nuclear substance licence. The licence included a condition that MMA would comply with an arrears payment schedule as set out in its licence. On August 20, 2021, MMA declared bankruptcy and CNSC staff undertook numerous actions as a result. An EIR was presented to the Commission on October 5, 2021, and an update was provided on November 23, 2021, during the presentation of the Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2020.

Since then, CNSC staff have continued to undertake 3 main activities related to this complex file:

- ensuring that the site remains safe and secure, and adapting the approach taken as site conditions change

- pursuing the provision of a contract to a third-party expert to undertake the detailed characterization of the waste

- working with other interested parties (e.g., bankruptcy trustee, key creditors, other levels of government) to find a solution regarding authority to undertake the needed work on the site (e.g., characterization, disposition)

The waste nuclear substance licence expired on February 28, 2022 and has not been renewed. The CNSC continues to ensure the safety and security of the nuclear substances on the site.

6.2 Update on the fatality at Kinectrics Inc.

On June 14, 2021, a contractor was providing services to Kinectrics Inc., another WNSL, when an industrial accident led to the fatality of one of the contractor’s employees. The Ministry of Labour, Training and Skills Development for the Province of Ontario was notified, and it began an investigation on June 14, 2021, which is expected to conclude in June 2022. An EIR was provided to the Commission at the October 5, 2021, meeting and CNSC staff will provide a further update during the presentation of this ROR in November 2022.

7.0 Public and stakeholder engagement

Appendix G includes a complete list of engagement activities undertaken in 2021.

The CNSC carries out stakeholder engagement and outreach activities to facilitate communication between the CNSC and the nuclear substance licensees and other stakeholders on licensed activities and regulatory expectations. To date, Indigenous Nations and communities have not expressed a specific interest in this ROR or in the licensed activities that it covers. However, upon request, CNSC staff have participated in general outreach activities with Indigenous Nations and communities to provide information on the packaging and transport of nuclear substances, but not specifically related to the licensees covered by this report. CNSC staff remain open and committed to ongoing engagement and communication with any interested Indigenous Nations and communities who may express an interest in discussing the topics and licenses covered in this ROR.

Stakeholder engagement and outreach are critical elements of the CNSC’s regulatory approach. Given the breadth of licensees regulated in the area of nuclear substances, a particular focus is on reaching and engaging with licensee communities, a practice that leads to increased awareness and better understanding of the regulatory process and requirements. CNSC staff leverage a variety of fora to engage with licensees and promote the use of the tools that are developed to support compliance with regulatory expectations.

In 2021, all outreach was done virtually or through written communications. Outreach included participation in town hall sessions, regular publication of the DNSR Digest, emails to targeted groups of licensees, meetings with associations or working groups, presentations at industry conferences, and the publishing of articles in industry publications. For a complete list of outreach activities, refer to appendix G.

8.0 International obligations and commitments

The mandate of the CNSC includes adherence to international commitments to which Canada is a party. CNSC staff had removed the section describing those commitments from previous RORs in the interest of streamlining the report. However, based on recent feedback from intervenors, this section has been reinserted.

Canada has committed to the implementation of various International Atomic Energy Agency (IAEA) codes, standards and guidance documents. For example, as part of Canada’s commitment to the IAEA Code of Conduct on the Safety and Security of Radioactive Sources, nuclear substance licensees with Category 1 and/or 2 (high-risk) sealed sources must inform the CNSC of any transfer, receipt, export or import of those sources. Licensees are to report their high-risk sealed sources inventory through the Sealed Source Tracking System (SSTS). The SSTS is a secure information management system that tracks new and existing high-risk sources within Canada. It populates the National Sealed Source Registry so that the information is as current as licence reporting allows. Licensees subject to this requirement have the relevant licence condition included on their licence, and compliance with this condition is verified through a regulatory inspection.

In addition, the CNSC considers international regulations and standards when developing domestic regulations. For example, the Packaging and Transport of Nuclear Substances Regulations, 2015, with which all licensees and non-licensees must comply, incorporate by reference the IAEA Regulations for the Safe Transport of Radioactive Material.

The Government of Canada also has obligations on the peaceful uses of nuclear energy pursuant to the Treaty on the Non-proliferation of Nuclear Weapons. CNSC requirements for nuclear substance licensees relating to Canada’s international obligations are defined in the applicable regulations and licences.

Safeguards is a system of inspection and other verification activities undertaken by the IAEA to evaluate Canada’s compliance with its obligations pursuant to its safeguards agreements with the IAEA. The objective of the Canada–IAEA safeguards agreements is for the IAEA to provide assurance to Canada and to the international community that all declared nuclear materials are in peaceful, non-explosive uses and that there is no indication of undeclared nuclear materials or activities. The CNSC has published REGDOC-2.13.1, Safeguards and Nuclear Material Accountancy, which sets out the requirements and guidance for the establishment and maintenance of a safeguards program. Safeguarded materials include uranium, thorium and plutonium-239. Generally, among the licensees covered in this report, this material can be present as samples, check sources and shielding, among other forms. Licensees subject to safeguards have a condition included on their licence, and the CNSC continues to engage with licensees to ensure that all nuclear material subject to safeguards is reported to the IAEA. In 2021, the IAEA performed 3 inspections and 4 complementary accesses at the facilities of nuclear substance licensees to confirm licensees’ declarations on the possession and use of nuclear material. While the IAEA reported that the results from these inspections were satisfactory and that its inspectors were able to carry out all planned activities for the complementary accesses, it identified follow-up actions for the licensees and/or the CNSC. The CNSC is coordinating the resolution of these items with the licensees.

Nuclear substance licensees who import or export nuclear substances are subject to licence conditions that limit the types and amounts of nuclear substances that can be imported or exported by the licensee without a separate, valid import/export licence. In addition, REGDOC-2.13.2, Import and Export, sets out guidance for current and prospective licensees who intend to import or export risk-significant radioactive sources (Category 1 and 2 radioactive sources). Compliance with import and export restrictions are verified as a part of standard regulatory oversight.

CNSC staff ensure that licensees implement the measures required to meet Canada’s international obligations and commitments.

9.0 Conclusion

In 2021, most inspected licensees were in compliance with regulatory requirements and achieved satisfactory ratings in the SCAs reported on in this report. Licensing and certification activities continued to play a critical role in ensuring that licensee programs were in place. Strong programs contributed to overall licensee performance. Where compliance did not meet expectations, licensees implemented appropriate corrective actions. All enforcement actions in 2021 have been closed. Radiation exposure to workers continued to be very low and was consistent with previous years. When events did occur, licensees took appropriate measures to address the events and took steps to prevent recurrence.

Regulatory oversight of licensees in 2021 was again impacted by the pandemic; however, a gradual return to in-person inspections, along with the use of hybrid and remote inspections, allowed for a more holistic inspection experience. After gaining experience with remote inspections in 2020, CNSC staff were able to pivot between remote, hybrid and in-person inspections, as the pandemic allowed, in 2021. Staff continue to address the backlog of inspections and will continue to monitor for possible negative trends in compliance over the coming years.

Overall, CNSC staff saw no significant changes in licence distribution, compliance trending, or doses to workers for any of the sectors covered by this report. Licensees corrected identified items of non-compliance to the satisfaction of CNSC staff. The evaluations of findings for the SCAs, resulting from the CNSC’s comprehensive regulatory oversight of the industry, demonstrate that licensees made acceptable provisions to protect health, safety, security and the environment from the use of nuclear substances and prescribed equipment, and implemented the measures required to meet Canada’s international obligations. Based on these evaluations, CNSC staff conclude that the use of nuclear substances and prescribed equipment in Canada remains safe and secure.

Appendix A: Regulatory program for the use of nuclear substances

This appendix presents additional regulatory data to complement the information provided in the main part of the document.

A.1 CNSC regulatory effort

CNSC designated officers made a total of 2,085 licensing and certification decisions related to activities covered in this report in 2021. The majority of these were licensing decisions, as shown in table 1. There was no significant change in the number or type of decisions made compared to 2020.

| Type of decision | Number of decisions |

|---|---|

| Licensing (issuance of new licences, licence renewals, licence amendments, licence revocations and licence transfers) | 1,621 |

| Certification of prescribed equipment (radiation devices, Class II prescribed equipment, and transport packages) | 70 |

| Certification of exposure device operators (EDOs) (issuance of new certifications and renewal of certifications) | 379 |

| Certification of Class II radiation safety officers (RSOs) | 15 |

| Total | 2,085 |

The CNSC’s risk-informed regulatory program applies resources and regulatory oversight commensurate with the risk associated with the regulated activity. Regulatory effort related to licensing, certification and compliance verification is derived from this program. As shown in table 2, CNSC staff’s direct effort for regulating the use of nuclear substances in 2021 amounted to 12,551 person days or the annual equivalent of approximately 57 full-time staff. This is slightly higher than the 11,698 person days (53 full-time staff) directed to this program in 2020.

| Activity | Person-days | Full-time equivalents |

|---|---|---|

| Licensing | 5,569 | 25.3 |

| Certification | 1,632 | 7.4 |

| Compliance verification | 5,350 | 24.3 |

A.2 Licensing

CNSC staff perform risk-informed technical assessments of applications submitted to the CNSC. The CNSC has produced a series of licence application guides to ensure that its expectations for applicants are clear, and to facilitate applicants’ interactions with the regulator.

In 2021, there were 2,097 nuclear substances and prescribed equipment licences held by 1,500 licensees in Canada (table 3). These licences were issued to entities throughout Canada, as shown in figure 1. In addition, 49 of these licences were issued to companies headquartered in other countries (primarily the United States). Many of these companies service prescribed equipment located in Canada, while others have operational facilities in Canada.

The disparity between the number of licences and the number of licensees can be explained by the fact that while most licensees perform a single licensed activity and therefore require only one CNSC licence, others perform varied activities that require a licence for each one. For example, a hospital may have multiple licences to cover radiation therapy facilities, diagnostic nuclear medicine, therapeutic nuclear medicine, nuclear substance processing, and research labs, each of which is covered by its own licence given the unique requirements and programs. CNSC staff work with these licensees to ensure that an appropriate level of regulatory control is maintained, while minimizing administrative burden wherever possible.

| Sector | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Medical | 457 | 436 | 438 | 445 | 440 |

| Industrial | 1,287 | 1,259 | 1,228 | 1,207 | 1,221 |

| Academic and research | 195 | 192 | 187 | 189 | 187 |

| Commercial | 252 | 248 | 237 | 238 | 249 |

| Total | 2,191 | 2,135 | 2,090 | 2,079 | 2,097 |

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Figure 1: Text version

The map shows the distribution of licences by sector across Canada.

Yukon: 4 industrial licences

Northwest Territories: 3 industrial licences

Nunavut: 0 licences

British Columbia: 174 industrial licences, 18 academic and research licences, 44 medical licences, 16 commercial licences (total of 252 licences)

Alberta: 303 industrial licences, 11 academic and research licences, 39 medical licences, 32 commercial licences (total of 385 licences)

Saskatchewan: 32 industrial licences, 5 academic and research licences, 11 medical licences, 2 commercial licences (total of 50 licences)

Manitoba: 27 industrial licences, 8 academic and research licences, 13 medical licences, 4 commercial licences (total of 52 licences)

Ontario: 382 industrial licences, 80 academic and research licences, 188 medical licences, 115 commercial licences (total of 765 licences)

Quebec: 207 industrial licences, 56 academic and research licences, 118 medical licences, 37 commercial licences (total of 418 licences)

New Brunswick: 28 industrial licences, 4 academic and research licences, 14 medical licences, 3 commercial licences (total of 49 licences)

Prince Edward Island: 2 industrial licences, 1 academic and research licence, 3 medical licences, 0 commercial licences (total of 6 licences)

Nova Scotia: 24 industrial licences, 3 academic and research licences, 5 medical licences, 4 commercial licences (total of 36 licences)

Newfoundland and Labrador: 20 industrial licences, 1 academic and research licence, 5 medical licences, 2 commercial licences (total of 28 licences)

A.3 Certification of prescribed equipment

Certification of prescribed equipment confirms that the prescribed equipment is safe to use; that adequate measures are in place to protect the environment, the health, safety and security of persons, and national security; and that the design meets international requirements. Prescribed equipment includes radiation devices, Class II prescribed equipment, and transport packages, and requirements for certification are set out in the regulations. As seen in table 1, designated officers made 70 decisions related to the certification of prescribed equipment in 2021, an increase over 2020 when 63 decisions were made. Similar to licensing, CNSC staff perform risk-informed technical assessments of certification applications submitted to the CNSC. The CNSC has regulatory documents in place to ensure that its expectations for applicants are clear. Service standards for the certification of Class II prescribed equipment, radiation devices, and transport packages were formalized in 2021 in response to the implementation of the Service Fees Act. Information on the service standards and CNSC performance can be found on the CNSC website.

A.4 Certification of exposure device operators

Licensees are required under the Nuclear Substances and Radiation Devices Regulations to permit only CNSC-certified personnel and supervised trainees to use exposure devices containing nuclear substances. In 2021, the CNSC certified 61 new exposure device operators (EDOs) and renewed the certifications of 318 others, which is very similar to 2020 when the CNSC certified 61 new EDOs and renewed 332 certifications. In 2021, CSA PCP-09, Exposure Device Operator Personnel Certification Guide, was updated. The updated version clarifies existing guidance and introduces new guidance to address common issues faced by applicants, employers and training providers.

A.5 Certification of Class II radiation safety officers

All licensees that operate Class II nuclear facilities or that service Class II prescribed equipment must have a certified radiation safety officer (RSO) and a qualified temporary replacement. The RSO ensures that licensed activities are conducted safely and that all regulatory expectations are met.

In 2021, the CNSC certified 15 Class II RSOs, compared to 24 certifications in 2020. As in 2020, there were no Class II RSOs decertified in 2021.

Appendix B: Compliance performance

This appendix provides details regarding compliance in the 4 SCAs determined to be the most relevant in providing an overall indication of the safety performance of licensees in 2021.

It is important to note that a below expectations rating does not necessarily mean that a licensee’s actions were unsafe. It could mean any of the following: licensee performance does not meet CNSC staff expectations, the licensee has risk-significant non-compliance(s) or performance issue(s), and/or non-compliances or performance issues are not being adequately corrected. Staff will issue unacceptable ratings in cases where licensee actions are unsafe – in 2021, only 5 unacceptable ratings were issued.

In all cases, for any below expectations ratings, CNSC staff ensured that licensees took appropriate corrective actions. For all unacceptable ratings, CNSC staff issued orders or took licensing action, with restrictions lifted only once the CNSC was satisfied that all conditions were addressed by the licensee.

B.1 Management system

Of the 489 inspections that looked at the management system SCA, 97% of the licensees inspected demonstrated that adequate processes and programs were in place to achieve their safety objectives and received satisfactory ratings (figures 2 and 3).

There were no unacceptable ratings in this SCA.

.jpg/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Figure 2: Text version

| N/A | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Satisfactory | 840 (97%) | 843 (97%) | 739 (97%) | 321 (96%) | 472 (97%) |

| Below expectations | 23 (3%) | 29 (3%) | 22 (3%) | 14 (4%) | 17 (3%) |

| Unacceptable | 1 (0.2%) | 0 (0%) | 3 (0.4%) | 0 (0%) | 0 (0%) |

| Total number of inspections | 864 | 872 | 764 | 335 | 489 |

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Figure 3: Text version

| N/A | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Medical | 106 (96%) | 110 (94%) | 155 (95%) | 44 (92%) | 101 (96%) |

| Industrial | 605 (98%) | 608 (97%) | 475 (98%) | 254 (96%) | 329 (97%) |

| Academic and research | 71 (97%) | 85 (99%) | 73 (99%) | 9 (100%) | 18 (100%) |

| Commercial | 58 (94%) | 40 (98%) | 36 (97%) | 14 (100%) | 24 (92%) |

| All sectors combined | 840 (97%) | 843 (99%) | 739 (97%) | 321 (97%) | 472 (97%) |

B.2 Operating performance

For the operating performance SCA, 87% of the licensees inspected ensured that adequate processes and programs were in place to achieve their safety objectives (figures 4 and 5) and received satisfactory ratings. Staff performed 531 inspections of this SCA.

There was 1 unacceptable rating issued to an industrial sector licensee in this SCA. Details on this unacceptable rating can be found in section 3.2 of this report.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Figure 4: Text version

| N/A | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Satisfactory | 747 (85%) | 747 (84%) | 672 (86%) | 292(83%) | 463 (87%) |

| Below expectations | 128 (15%) | 144 (16%) | 110 (14%) | 61 (17%) | 67 (13%) |

| Unacceptable | 8 (1%) | 4 (0.4%) | 2 (0.3%) | 0 (0%) | 1 (0.2%) |

| Total number of inspections | 883 | 895 | 784 | 353 | 531 |

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Figure 5: Text version

| N/A | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Medical | 100 (86%) | 96 (77%) | 155 (88%) | 41 (80%) | 97 (84%) |

| Industrial | 511 (82%) | 528 (83%) | 409 (85%) | 225 (84%) | 318 (88%) |

| Academic and research | 73 (97%) | 79 (88%) | 70 (95%) | 9 (90%) | 22 (96%) |

| Commercial | 63 (94%) | 44 (92%) | 38(89%) | 17 (94%) | 26 (87%) |

| All sectors combined | 747 (85%) | 747 (84%) | 672 (86%) | 292 (83%) | 463 (87%) |

B.3 Radiation protection

In 2021, 561 inspections were conducted to evaluate compliance with the radiation protection SCA. Of the licensees inspected, 83% ensured that adequate processes and programs were in place to achieve their safety objectives and received satisfactory ratings (figures 6 and 7).

Three industrial sector licensees received an unacceptable rating in this SCA. Details on these unacceptable ratings can be found in section 3.3 of this report.

.jpg/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Figure 6: Text version

| N/A | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Satisfactory | 744 (85%) | 748 (84%) | 629 (80%) | 299 (84%) | 465 (83%) |

| Below expectations | 129 (15%) | 137 (15%) | 160 (20%) | 55 (16%) | 93 (17%) |

| Unacceptable | 3 (0.3%) | 6 (0.7%) | 1 (0.1%) | 1 (0.3%) | 3 (0.5%) |

| Total number of inspections | 876 | 891 | 790 | 355 | 561 |

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Figure 7: Text version

| N/A | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Medical | 94 (81%) | 95 (77%) | 132 (74%) | 42 (82%) | 113 (78%) |

| Industrial | 518 (84%) | 539 (85%) | 387 (80%) | 227 (85%) | 308 (85%) |

| Academic and research | 69 (93%) | 68 (77%) | 71 (96%) | 9 (90%) | 18 (78%) |

| Commercial | 63 (100%) | 46 (100%) | 39(81%) | 21 (100%) | 26 (90%) |

| All sectors combined | 744 (85%) | 748 (84%) | 629 (80%) | 299 (84%) | 465 (83%) |

B.4 Security

For the security SCA, 91% of the licensees inspected ensured that adequate processes and programs were in place to achieve their safety objectives and received satisfactory ratings (figures 8 and 9). Staff performed 228 inspections of this SCA.

One industrial sector licensee received an unacceptable rating for the security SCA. Details on this unacceptable rating can be found in section 3.4 of this report.

.jpg/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Figure 8: Text version

| N/A | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Satisfactory | 764 (90%) | 764 (92%) | 719 (95%) | 163 (93%) | 208 (91%) |

| Below expectations | 77 (9%) | 68 (8%) | 41 (5%) | 13 (7%) | 19 (8%) |

| Unacceptable | 9 (1.1%) | 1 (0.1%) | 0 (0%) | 0 (0%) | 1 (0.4%) |

| Total number of inspections | 850 | 833 | 760 | 176 | 228 |

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Figure 9: Text version

| N/A | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Medical | 96 (81%) | 96 (91%) | 158 (94%) | 31 (94%) | 27 (79%) |

| Industrial | 552 (93%) | 587 (94%) | 457 (94%) | 116 (95%) | 155 (93%) |

| Academic and research | 66 (97%) | 57 (79%) | 72 (99%) | 7 (100%) | 10 (91%) |

| Commercial | 50 (94%) | 46 (93%) | 32 (91%) | 9 (90%) | 16 (100%) |

| All sectors combined | 764 (90%) | 786 (94%) | 719 (95%) | 163 (93%) | 208 (91%) |

B.5 Inspection ratings by sector