Regulatory Oversight Report for Uranium and Nuclear Substance Processing Facilities in Canada: 2020

Table of contents

- Changes to 2020 regulatory oversight report

- Plain language summary

- 1 Introduction

- 2 Uranium processing facilities

- 3 Nuclear substance processing facilities

- 4 Research reactor facilities

- 5 CNSC regulatory oversight

- 6 The CNSC’s assessment of safety at uranium and nuclear substance processing facilities and research reactors

- 6.1 Management System

- 6.2 Human Performance Management

- 6.3 Operating Performance

- 6.4 Safety Analysis

- 6.5 Physical Design

- 6.6 Fitness for Service

- 6.7 Environmental Protection

- 6.8 Radiation Protection

- 6.9 Conventional Health and Safety

- 6.10 Emergency Management and Fire Protection

- 6.11 Waste Management

- 6.12 Security

- 6.13 Safeguards and Non-Proliferation

- 6.14 Packaging and Transport

- 7 The CNSC’s assessment of safety at uranium and nuclear substance processing facilities and research reactors

- 8 Overall conclusions

- References

- Acronyms and Abbreviations

- Glossary

- A. Links to Licensee Websites and Annual Compliance Reports

- B. CNSC Inspections

- C. Significant Changes to Licences and Licence Conditions Handbooks

- D. Regulatory Document Implementation

- E. Financial Guarantees

- F. Safety and Control Area Ratings

- G. Total Annual Releases of Radionuclides Directly to the Environment

- H. Public Dose Data

- I. Environmental Data

- J. Worker Dose Data

- K. Health and Safety Data

- L. Reportable Events

- M. List of Identified Indigenous Nations and Communities With an Interest in Uranium and Nuclear Substance Processing Facilities

- N. Participant Funding Recipients for the 2020 UNSPF and RRs Regulatory Oversight Report

Changes to 2020 regulatory oversight report

As with other regulatory oversight reports (RORs) produced by the Canadian Nuclear Safety Commission (CNSC), changes have been made to this report as a result of recommendations from the Commission and feedback from intervenors. CNSC staff made the following changes to the Regulatory Oversight Report for Uranium and Nuclear Substance Processing Facilities and Research Reactors in Canada: 2020:

- Performance reporting for research reactors is done on a 3-year frequency. These facilities were previously part of the RORs for nuclear research reactors and particle accelerator facilities, but will be included in this ROR from now on.

- Indigenous Nations and communities and their traditional and/or treaty territories are acknowledged at the beginning of the ROR and presentation.

- The executive summary was replaced with a plain language summary.

- Further details on all safety and control areas are included.

- More hyperlinks are used as content is readily available online (e.g., CNSC website, past regulatory oversight reports, etc.).

- Data provided for the Independent Environmental Monitoring Program includes an explanation on changes to analytical techniques.

Plain language summary

The Regulatory Oversight Report for Uranium and Nuclear Substance Processing Facilities and Research Reactors in Canada: 2020 provides information on the safety performance of the nuclear facilities named in the title. The report is based on CNSC staff’s work to ensure safety and protection for the people and the environment for licenced uranium and nuclear substance processing facilities (UNSPF), as well as research reactors (RRs). Over the reporting periods covered, all facilities continued to operate safely; monitoring data shows that food grown nearby is safe to eat, and that water is safe to drink. There were no releases that could have harmed human health or the environment.

This report also provides an update on CNSC staff regulatory activities pertaining to public information, community engagement, and aspects of the CNSC’s Independent Environmental Monitoring Program that relate to UNSPF and RRs. Where possible, trends are shown and information is compared to previous years.

This report provides information on the following licenced facilities in Canada:

- Uranium processing facilities

- Cameco Corporation Blind River Refinery in Blind River, Ontario

- Cameco Corporation Port Hope Conversion Facility in Port Hope, Ontario

- Cameco Fuel Manufacturing Inc. in Port Hope, Ontario

- BWXT Nuclear Energy Canada Inc. in Toronto, Ontario

- BWXT Nuclear Energy Canada Inc. in Peterborough, Ontario

- Nuclear substance processing facilities

- SRB Technologies (Canada) Inc. in Pembroke, Ontario

- Nordion (Canada) Inc. in Ottawa, Ontario

- Best Theratronics Ltd. in Ottawa, Ontario

- Research reactors

- Polytechnique de Montréal SLOWPOKE-2 research reactor in Montréal, Quebec

- McMaster Nuclear Reactor in Hamilton, Ontario

- Royal Military College of Canada SLOWPOKE-2 research reactor in Kingston, Ontario

- Saskatchewan Research Council SLOWPOKE-2 research reactor in Saskatoon, Saskatchewan

Each year, CNSC inspectors complete inspections at these facilities. The number of inspections and what is inspected depend on the individual site and how the facility has been performing. The CNSC uses a risk-informed approach when planning inspections. Over the respective reporting periods, CNSC staff performed a total of 28 inspections at the UNSPF and RRs. These inspections resulted in the issuance of 47 notices of non-compliance (NNC), which were all related to issues identified as low risk. In addition, to ensure non-proliferation obligations were met, 39 International Atomic Energy Agency (IAEA) initiated safeguards verification activities and 1 CNSC-initiated safeguards field activity were performed at the UNSPF and RRs. These regulatory activities resulted in the issuance of 3 NNCs, which were all related to issues identified as low risk. All NNCs are described in section 6 and section 7.2.2 of this report.

The CNSC uses 14 safety and control areas (SCAs) to evaluate the performance of each licensee, for which the resulting performance ratings are included in this report. Particular focus is placed on the radiation protection, environmental protection, and conventional health and safety SCAs, as these give a good overview of safety performance.

The SCA ratings in this report were derived from the results of activities conducted by CNSC staff to verify compliance. These activities included onsite and virtual inspections, technical assessments, reviews of reports submitted by licensees, reviews of events and incidents, and ongoing exchanges of information with licensees. For the periods reported on, CNSC staff rated all SCAs as "satisfactory" for all facilities contained in this report, and confirmed that all were operating safely.

The CNSC recognizes and understands the importance of building relationships with Indigenous Nations and communities in Canada. The CNSC’s goal is to build partnerships and trust through cooperative engagement activities. The facilities discussed in this report lie within the traditional and/or treaty territories of many Indigenous Nations and communities.

In 2020, the activities undertaken by CNSC staff supported their ongoing commitment to meeting consultation and accommodation obligations, and to continuing to build relationships with Indigenous Nations and communities with interests in Canada’s UNSPF and RRs.

In summary, workers at each facility were safe and properly protected and there were no releases that could have harmed the surrounding environments or the health and safety of Indigenous Nations and communities or people.

This report is available on the CNSC website, and the documents referenced in it are available to the public upon request by contacting:

Senior Tribunal Officer, Secretariat

Tel.: 613-858-7651 or 1-800-668-5284

Fax: 613-995-5086

Email: interventions@cnsc-ccsn.gc.ca

1 Introduction

Through the application of the Nuclear Safety and Control Act (NSCA) [1], and its associated Regulations, the Canadian Nuclear Safety Commission (CNSC) regulates Canada’s nuclear industry to protect the health and safety of persons and the environment and to implement Canada’s international commitments on the peaceful use of nuclear energy. The CNSC also disseminates objective scientific, technical and regulatory information to the public. Licensees are responsible for operating their facilities safely, and are required to implement programs that make adequate provision for meeting legislative and regulatory requirements and licence conditions.

This regulatory oversight report (ROR) provides an overview of CNSC regulatory efforts and staff’s assessment of uranium and nuclear substance processing facilities (UNSPF) in Canada for the 2020 calendar year. This report also provides CNSC staff’s assessment of research reactors (RRs) from 2018 to 2020, on which the Commission has directed CNSC staff to provide updates every 3 years.

The facilities covered by this report are:

- Uranium processing facilitiesFootnote 1

- Cameco Corporation Blind River Refinery (BRR) in Blind River, Ontario

(FFOL-3632.00/2022) - Cameco Corporation Port Hope Conversion Facility (PHCF) in Port Hope, Ontario (FFOL-3631.00/2027)

- Cameco Fuel Manufacturing Inc. (CFM) in Port Hope, Ontario

(FFOL-3641.00/2022) - BWXT Nuclear Energy Canada Inc. (formerly GE Hitachi Nuclear Energy Canada Inc.) in Toronto, Ontario (BWXT-NEC Toronto) (FFL-3621.00/2030)

- BWXT Nuclear Energy Canada Inc. (formerly GE Hitachi Nuclear Energy Canada Inc.) in Peterborough, Ontario (BWXT-NEC Peterborough)

(FFL-3620.00/2030)

- Cameco Corporation Blind River Refinery (BRR) in Blind River, Ontario

- Nuclear substance processing facilities1

- SRB Technologies (Canada) Inc. (SRBT) in Pembroke, Ontario

(NSPFOL-13.00/2022) - Nordion (Canada) Inc. (Nordion) in Ottawa, Ontario (NSPFOL-11A.01/2025)

- Best Theratronics Ltd. (BTL) in Ottawa, Ontario (NSPFOL-14.00/2029)

- SRB Technologies (Canada) Inc. (SRBT) in Pembroke, Ontario

- Research reactors1

- Polytechnique Montréal SLOWPOKE-2 research reactor in Montréal, Quebec (PERFP-9A.01/2023)

- McMaster Nuclear Reactor (MNR) in Hamilton, Ontario (NPROL‐01.01/2024)

- Royal Military College of Canada (RMC) SLOWPOKE-2 research reactor in Kingston, Ontario (NPROL-20.00/2023)

- Saskatchewan Research Council (SRC) SLOWPOKE-2 research reactor in Saskatoon, Saskatchewan (NPROL-19.01/2023)

This report discusses all safety and control areas (SCAs), but focuses on radiation protection, environmental protection, and conventional health and safety, as they provide a good overview of safety performance at licensed facilities. The report also provides an overview of licensee operations, licence changes, major developments at licensed facilities and sites, and reportable events. In addition, the report includes information on public information programs, COVID-19 responses by licensees and the CNSC, and engagement with Indigenous Nations and communities.

2 Uranium processing facilities

Uranium processing facilities are part of the nuclear fuel cycle that includes refining, conversion and fuel manufacturing. The fuel produced is used in nuclear power plants for the generation of electricity.

2.1 Cameco Blind River Refinery

Cameco Corporation owns and operates the Blind River Refinery (BRR) in Blind River, Ontario. The facility is located about 5 km west of the town of Blind River and south of Mississauga First Nation, as shown in figure 2-1.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

(Source: Cameco)

The BRR facility refines uranium concentrates (yellowcake) received from uranium mines worldwide to produce uranium trioxide (UO3), an intermediate product of the nuclear fuel cycle. The primary recipient of the UO3 is Cameco’s Port Hope Conversion Facility (PHCF).

In 2020, CNSC staff conducted 3 inspections at the BRR that covered 7 SCAs. Table B-1 in appendix B lists these inspections and the 4 resulting notices of non-compliance (NNCs) are highlighted in section 6 of this report.

CNSC staff are satisfied that Cameco’s BRR was operated safely in 2020 and in accordance with its licensing basis.

In September 2020, CNSC staff received Cameco’s application for a 10-year renewal of its fuel facility operating licence for BRR. BRR’s licence expired on February 28, 2022, and a Commission hearing took place on November 24, 2021. The Commission renewed the BRR licence for a 10-year period as per the Record of Decision.

2.2 Cameco Port Hope Conversion Facility

Cameco Corporation owns and operates the Port Hope Conversion Facility (PHCF), which is located in Port Hope, Ontario, situated on the north shore of Lake Ontario, approximately 100 km east of Toronto. Figure 2-2 shows an aerial view of the PHCF.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

(Source: Cameco)

PHCF converts UO3 powder produced by Cameco’s BRR into uranium dioxide (UO2) and uranium hexafluoride (UF6). UO2 is used in the manufacturing of Canada Deuterium Uranium (CANDU) reactor fuel, while UF6 is exported for further processing before being converted into fuel for light-water reactors.

In 2020, CNSC staff conducted 3 inspections at PHCF that covered 9 SCAs, as well as compliance verification activities associated with the Vision in Motion (VIM) project. Table B-2 of appendix B lists these inspections and the 8 resulting NNCs are highlighted in section 6 of report.

CNSC staff are satisfied that Cameco’s PHCF operated safely in 2020 and in accordance with its licensing basis.

Vision in motion

VIM is Cameco’s project to clean up and renew the site. The project is being carried out under Cameco’s operating licence FFOL-3631.00/2027. Licence condition 16.1 requires that "The licensee shall implement and maintain a program to carry out clean-up, decontamination and remediation work". Cameco postponed some non-essential VIM work to limit the amount of contractors onsite during the COVID-19 pandemic. In 2020, Cameco carried out VIM work that included:

- Preparation and transfer of stored wastes to the CNSC-licensed Canadian Nuclear Laboratories (CNL) Port Hope Project Long-Term Waste Management Facility

- Removal of interior equipment and accumulated waste materials in Building 27 (the former UF6 plant)

- Installation of infrastructure, including new storm water management systems and the new hydrogen station were substantially completed. Commissioning is planned for 2022. The Ontario Ministry of the Environment, Conservation and Parks environmental compliance approval amendment for stormwater was received and the new stormwater system at the south end of the facility began operation

- Conduct of species-at-risk desktop studies and species surveys in VIM work areas

- Conduct of a subsurface geotechnical drilling investigation in the location of proposed storm water infrastructure

In December 2020, Cameco provided an update to the Commission (CMD 20-M36.1) on the VIM project.

2.3 Cameco Fuel Manufacturing Inc.

Cameco Fuel Manufacturing Inc. (CFM) is a wholly owned subsidiary of Cameco Corporation. CFM operates 2 facilities: a nuclear fuel fabricating facility licensed by the CNSC in Port Hope, Ontario; and a metals manufacturing facility in Cobourg, Ontario, which manufactures fuel bundle and reactor components (non-nuclear activities). This latter facility is not licensed by the CNSC and is not discussed further in this report. Figure 2-3 shows an aerial view of the CFM facility.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

(Source: Cameco)

The CFM facility manufactures fuel pellets from natural UO2 powder and assembles nuclear reactor fuel bundles. The finished fuel bundles are primarily shipped to Canadian nuclear power reactors.

In 2020, CNSC staff conducted 3 inspections at CFM that covered 5 SCAs. Table B-3 of appendix B lists these inspections and the 9 resulting NNCs are highlighted in section 6 of this report.

CNSC staff are satisfied that CFM operated safely in 2020 and in accordance with its licensing basis.

In December 2020, CNSC staff received Cameco’s application for a 1-year renewal of its fuel facility operating licence for CFM that expired on February 28, 2022. The Commission conducted a hearing in writing to consider submissions from Cameco and CNSC staff, as well as interventions from the Public and Indigenous Nations and communities. The Commission granted CFM a 1-year licence renewal (February 28, 2023) as per the Record of Decision. CFM is currently applying for a 20-year licence renewal.

2.4 BWXT Nuclear Energy Canada Inc.

BWXT Nuclear Energy Canada Inc. (BWXT-NEC) produces nuclear fuel and fuel bundles used by Ontario Power Generation’s Pickering and Darlington nuclear generating stations. BWXT-NEC has licensed operations in 2 locations: Toronto and Peterborough, Ontario. Figures 2-4 and 2-5 show aerial views of the BWXT-NEC facilities.

(Source: Google Maps)

(Source: Google Maps)

The Toronto facility produces CANDU nuclear fuel pellets using UO2 supplied from the PHCF. The Peterborough facility manufactures CANDU nuclear fuel bundles, using the uranium pellets from Toronto and zircaloy tubes manufactured in-house. The Peterborough facility also runs a fuel services business involved with the manufacturing and maintenance of equipment for use in nuclear power plants.

In 2020, CNSC staff conducted 4 inspections at BWXT-NEC that covered 4 SCAs. Table B-4 of appendix B lists these inspections and the 4 resulting NNCs are highlighted in section 6 and section 7 of this report

Significant facility modifications included changes in Peterborough to include automation equipment dealing with sorting and stacking of fuel pellets received from the Toronto facility. All facility modifications were conducted under the facility change control process and CNSC staff are satisfied that the BWXT-NEC facilities operated safely in 2020 and in accordance with their licensing basis.

2.4.1 2020 BWXT-NEC Licence Renewal

In March 2020, the Commission conducted public hearings in Toronto, Ontario and Peterborough, Ontario on the renewal of BWXT-NEC’s operating licence. CNSC staff’s assessment of the renewal application was presented publicly during this hearing as CMD 20-H2.A and CMD 20-H2.B. As well, CNSC staff submitted CMD 20-H2.C in response to several undertakings provided to the Commission for more information.

In April 2020, the Commission announced a continuation of hearing and directed CNSC staff to collect additional soil samples of beryllium on properties adjacent to BWXT-NEC’s Peterborough facility. CNSC staff completed the resampling and provided a supplementary submission to the Commission as CMD 20-H2.D and CMD 20-H2.E.

In December 2020, the Commission made a decision on the BWXT-NEC licence renewal application as documented in the record of decision 20-H2. In its decision, the Commission decided to renew BWXT-NEC’s licence as 2 facility-specific licences (FFL-3621.00/2030 and FFL-3620.00/2030) for a period of 10 years. As the decision details, the Commission also permitted the conduct of pelleting operations at the Peterborough facility with conditions (e.g., updated safety analysis report and final commissioning report) and accepted BWXT-NEC’s proposed new financial guarantee. Further, the Commission issued several directions to CNSC staff on Indigenous and public engagement, the status of which is reported in sections 7.2 and 7.3 of this report.

3 Nuclear substance processing facilities

Nuclear substance processing facilities use nuclear substances to manufacture various products for end uses in industrial or medical applications. The nuclear substances can be used for lighting self-luminous emergency and exit signs, sterilizing items for sanitary reasons such as surgical gloves, and providing cancer diagnosis and treatment.

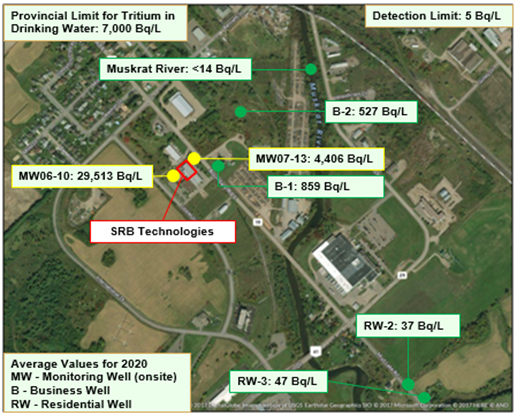

3.1 SRB Technologies (Canada) Inc.

SRB Technologies (Canada) Inc. (SRBT) operates a Class IB facility that manufactures gaseous tritium light sources, on the outskirts of Pembroke, Ontario, approximately 150 km northwest of Ottawa. The nuclear facility has been in operation since 1990 and employs approximately 40 employees. Figure 3-1 shows an aerial view of the SRBT facility.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

(Source: SRBT)

The SRBT facility produces sealed glass capsules coated with phosphorescent powder and filled with tritium gas to generate continuous light. Examples of gaseous tritium light sources made at the facility include signs, markers and tactical devices. SRBT distributes its products in Canada and internationally.

In 2020, CNSC staff conducted 2 inspections at SRBT that covered 2 SCAs. Table B-5 of appendix B lists these inspections and the 3 resulting NNCs are highlighted in section 6 of this report.

CNSC staff are satisfied that SRBT operated safely in 2020 and in accordance with its licensing basis.

CNSC staff were expecting to receive SRBT’s application for a nuclear substance processing facility licence in 2021, as it is due for renewal in June 2022.

3.2 Nordion (Canada) Inc.

Nordion (Canada) Inc. is located in Ottawa, Ontario, and is licensed to operate a Class IB nuclear substance processing facility. Figure 3-2 shows an aerial view of the Nordion facility.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

(Source: Google Maps)

The facility is composed of 2 major production operations. One operation involves the processing of radioisotopes used in nuclear medicine (medical isotopes) such as yttrium-90. The other operation involves manufacturing sealed sources (cobalt-60) used in cancer therapy and irradiation technologies (gamma technologies).

In April 2018, BWX Technologies Ltd. (BWXT) announced an agreement to acquire Nordion’s medical isotope business. The acquisition was completed in August 2018, as a wholly owned subsidiary of BWXT, BWXT Medical Ltd (BWXT-MED). Nordion continued to operate the medical isotope facility until BWXT-MED obtained a separate Class IB nuclear substance processing facility operating licence. The licensing hearing took place in June 2021 and BWXT-MED was issued a 10-year licence as per the Record of Decision.

In 2020, CNSC staff conducted 2 inspections at Nordion that covered 7 SCAs. Table B-6 of Appendix B lists these inspections and the 3 resulting NNCs are highlighted in section 6 of this report.

CNSC staff are satisfied that Nordion operated safely in 2020 and in accordance with its licensing basis.

3.3 Best Theratronics Ltd.

Best Theratronics Ltd. (BTL) owns and operates a medical device manufacturing facility in Ottawa, Ontario. Figure 3-3 shows an aerial view of the BTL facility.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

(Source: Google Maps)

BTL manufactures cyclotrons and medical equipment, including cobalt-60-based external beam radiation therapy units and cesium-137 self-contained irradiators for blood irradiation. BTL is licensed by the CNSC for the development and testing of cobalt‑60 teletherapy devices, the manufacturing of self-shielded irradiators, the storage of nuclear substances, and construction and testing of particle accelerators (cyclotrons) with beam energies ranging from 15 to 70 MeV.

In 2020, CNSC staff conducted 2 inspections at BTL that covered 2 SCAs. Table B-7 of appendix B lists these inspections and the 6 resulting NNCs are highlighted in section 6 of this report.

CNSC staff are satisfied that BTL operated safely in 2020 and in accordance with its licensing basis.

4 Research reactor facilities

This section discusses the CNSC’s regulatory oversight and licensee performance of small RRs in Canada, including the McMaster Nuclear Reactor (MNR) and 3 SLOWPOKE-2 reactors: Polytechnique Montréal, Saskatchewan Research Council (SRC) and Royal Military College of Canada (RMC).

CNSC staff first reported on nuclear research reactor (RR) facilities in 2015, in the Regulatory Oversight Report for Nuclear Processing, Small Research Reactor and Class 1B Accelerator Facilities: 2015. These facilities were then reported on again in 2018 during the ROR for Research Reactors and Class 1B Accelerators: 2016, and are now on a 3-year reporting frequency. This ROR covers reporting years 2018 to 2020. In 2021, for operational efficiency, CNSC staff decided to include RRs in this report, going forward.

The small RRs operating in Canada are designed to operate at low power, ranging from 0.02 megawatts (MW) for SLOWPOKE-2 reactors to 5 MW for the MNR. SLOWPOKE-2 reactors are self-limiting in power and temperature, without the need for operator intervention or automatic trip systems. They also use natural circulation for cooling, eliminating the need for complex cooling systems. These small RRs are typically used for academic purposes, medical isotope production, neutron radiography and neutron activation analysis for a number of industries including mining and geological surveys. Figure 4-1 shows a model of a SLOWPOKE-2 reactor core.

(Source: RMC)

They do not release liquid effluents, and their airborne releases are extremely small. A conservative evaluation of the dose to the public through airborne releases results in less than 1microsievert (μSv)/year, which is less than 1/1000 of the regulatory dose limit of 1 millisievert (mSv) for a member of the public. As a point of reference, the average effective dose to persons from natural background radiation in Canada is estimated at 1.8 mSv/year.

With their inherent safety characteristics and low power, these reactors present a very low risk.

4.1 Polytechnique Montréal SLOWPOKE-2

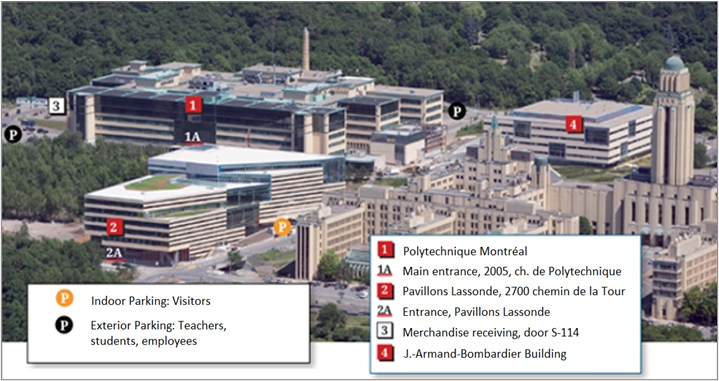

Polytechnique Montréal operates a SLOWPOKE-2 reactor in Montréal, Québec, for which a licence was issued by the CNSC in 2016, for a period of 7 years. The reactor was initially commissioned in 1976 and the fuel was replaced in 1997 with low enriched uranium (LEU) fuel. Polytechnique Montréal expects to operate the reactor until 2032. The reactor is used for research, neutron analysis, teaching and isotope production. The Polytechnique Montréal campus is shown in figure 4-2.

The Polytechnique Montréal SLOWPOKE-2 facility includes a subcritical assembly, located in a room next to the reactor. The assembly consists of natural uranium bars and neutron sources that are manually inserted into graphite blocks. The subcritical assembly has been used in the past for teaching and research purposes, but has not operated since 2012.

(Source: Polytechnique Montréal)

CNSC staff conducted 2 inspections at Polytechnique Montréal from 2018 to 2020 that covered 10 SCAs. Table B-8 of appendix B lists these inspections and the 4 resulting NNCs are highlighted in section 6 of this report.

CNSC staff are satisfied that Polytechnique Montréal operated safely over the 2018–20 period and in accordance with its licensing basis. No operational issues or events were reported over the 2018–20 period.

CNSC staff will be prepared to receive Polytechnique Montréal’s application for a SLOWPOKE-2 reactor operating licence in 2022, as it is due for renewal in July 2023.

4.2 McMaster Nuclear Reactor

McMaster University operates the MNR, a medium flux reactor in Hamilton, Ontario. A licence was issued by the CNSC in 2014 for a period of 10 years. The reactor became operational in 1959, and it was upgraded in the 1970s to operate at 5 MW, up from the 1 MW maximum. The reactor is used for research, materials testing, teaching and isotope production.

This pool-type reactor uses LEU as fuel and has the added safety feature of a full containment building. The reactor produces iodine-125 for medical use in Canada and for international markets. The MNR is also used for neutron radiography, which is performed daily, for the testing of aircraft engine components. In addition to supporting the research work of McMaster University physics and engineering undergraduate and post-graduate students, the MNR is used for the irradiation of more than 10,000 mineral and other samples every year for various applications such as biomedical research, material science and geological surveys. Figure 4-3 shows an image of the MNR containment building, and figure 4-4 provides an overhead view of the MNR in operation.

(Source: McMaster University)

(Source: McMaster University)

From 2018 to 2020, CNSC staff conducted 3 inspections at the MNR, which covered 13 SCAs, as well as the public and information disclosure program. Table B-9 of appendix B lists these inspections and the 6 resulting NNCs are highlighted in section 6 of this report.

CNSC staff are satisfied that the MNR operated safely over the 2018–20 period and in accordance with its licensing basis.

4.3 Royal Military College of Canada SLOWPOKE-2

RMC operates a SLOWPOKE-2 facility, at the RMC complex in Kingston, Ontario. The licence was issued by the CNSC in 2013 for a period of 10 years.

This facility is made up of the reactor room, with the reactor and control room located on the first floor, and laboratories on the first and second floors of the Sawyer Science and Engineering Building, Module 5. This building is shown in figure 4-5, indicated by the red dot.

(Source: RMC)

This facility is used for neutron activation analysis, analysis of fissile materials, neutron radiography and radioscopy, and education in radiation protection at the post-graduate level. The reactor has been in operation since 1985, and the core is fueled with LEU.

The type of operations remained the same over the review period. RMC has undertaken a project to refuel the SLOWPOKE-2 reactor as the fuel core has attained its end of life, and the project is on schedule for completion by the end of 2021. CNSC staff are engaged in the review of the project and the refueling operations.

From 2018 to 2020, CNSC staff conducted 2 inspections at RMC, which covered 11 SCAs, along with the public information and disclosure program. Table B-10 of appendix B lists these inspections and the 2 resulting NNCs are highlighted in section 6 of this report.

CNSC staff are satisfied that RMC operated safely over the 2018–20 period and in accordance with its licensing basis.

CNSC staff will be prepared to receive RMC’s application for a SLOWPOKE-2 reactor operating licence in 2022, as it is due for renewal in July 2023.

4.4 Saskatchewan Research Council SLOWPOKE-2

SRC was operating the SLOWPOKE-2 facility, for which a 10-year licence was issued by the CNSC in 2013. The reactor came online in 1981, and was shut down for decommissioning in April 2019. In December 2019, following a public hearing, a licence amendment was approved by the Commission, allowing SRC to begin decommissioning.

The SRC SLOWPOKE-2 facility was located within the Innovation Place Research Park in Saskatoon, Saskatchewan, as shown by the red circle in figure 4-6. Prior to decommissioning, the facility consisted of a reactor room, a laboratory and a waste storage room. The facility was used for neutron activation analysis, delayed neutron analysis and teaching in conjunction with the University of Saskatchewan.

(Source: Google Maps)

On August 15, 2019, the highly enriched uranium (HEU) fuel was removed from the reactor pool in the presence of representatives from the IAEA, CNSC and the United States Department of Energy (U.S. DOE). The HEU fuel was loaded into a transport flask and sealed by the IAEA for safeguards purposes, and was transported to the U.S. DOE’s Savannah River site in South Carolina.

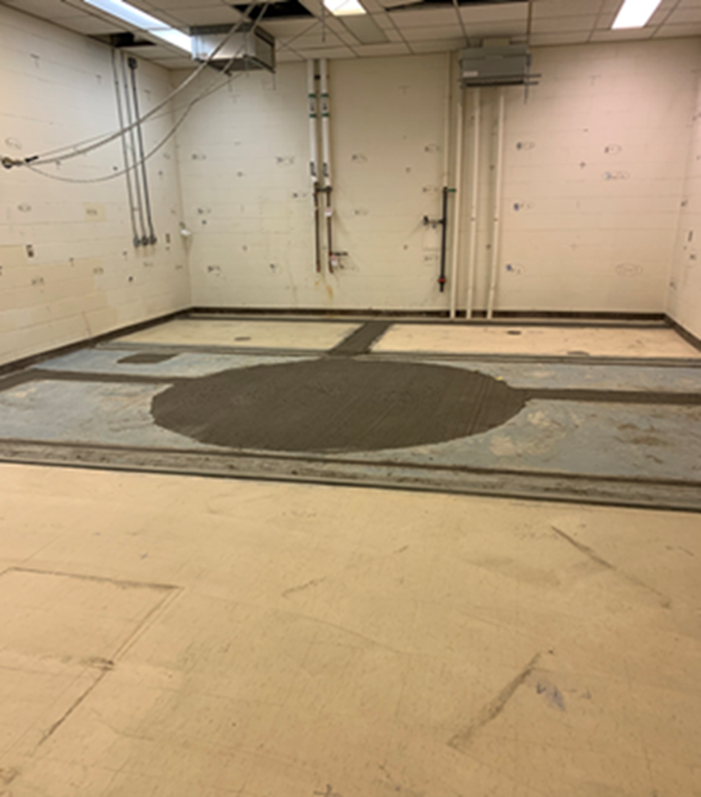

CNSC staff conducted a remote Type II compliance inspection of SRC from July 8 to 10, 2020. The inspection verified that the decommissioning activities were conducted safely and in compliance with the NSCA, its associated Regulations, the licence, detailed decommissioning plan and supporting documentation. Figure 4-7 shows the SRC pool and overflow channels filled with grout, as part of the decommissioning activities.

(Source: SRC)

As highlighted in section 6, CNSC staff raised 1 NNC with respect to waste characterization reports. This was resolved in the following weeks with the submission of additional waste characterization details and SRC’s end state report for the decommissioning of the SRC reactor facility.

SRC completed decommissioning activities in 2020. There are no nuclear activities, nuclear substances, equipment nor contamination above the unconditional release limits present in the building. The building can be repurposed for any non-nuclear activities without any restrictions. SRC have requested the revocation of the non-power reactor operating licence and requested a licence to abandon a nuclear facility on October 27, 2020.

On October 1, 2021, the Commission issued SRC a licence to abandon a non-power SLOWPOKE-2 reactor facility. The SRC SLOWPOKE-2 facility was released from CNSC regulatory control, and the financial guarantee held for the decommissioning of the facility was released.

In total, CNSC staff conducted 2 inspections at SRC from 2018 to 2020 that

covered 7 SCAs. Table B-11 of appendix B lists these inspections and the aforementioned NNC is highlighted in section 6 of this report.

CNSC staff are satisfied that SRC operated safely over the 2018–20 period and in accordance with its licensing basis.

5 CNSC regulatory oversight

The CNSC performs regulatory oversight of licensed facilities to verify compliance with the requirements of the NSCA and associated regulations made under the NSCA, each site’s licence and licence conditions, and any other applicable standards and regulatory documents.

CNSC staff use the SCA framework to assess, evaluate, review, verify and report on licensee performance. The SCA framework includes 14 SCAs, which are subdivided into specific areas that define its key components. Further information on the CNSC’s SCA framework can be found on the CNSC’s website.

5.1 Regulatory activities

CNSC staff conducted risk-informed regulatory oversight activities at Canada’s UNSPF (2020) and RRs (2018–20). Table 5-1 presents CNSC staff’s licensing and compliance verification efforts for these facilities for the reportable years. Of note is the high number for BWXT-NEC and SRC licensing activities. The BWXT-NEC person-days for licensing activities are higher due to licence renewal efforts for the Toronto and Peterborough facilities, while the SCR numbers were higher due to the decommissioning of the facility and the requested licence to abandon, as described in section 4.4 of this report.

| Facility type | Site | Number of inspections | Person-days for compliance verification activities | Person-days for licensing activities | Number of IAEA-initiated safeguards verification activities | Number of CNSC-initiated safeguards field activities |

|---|---|---|---|---|---|---|

| UNSPF | BRR | 3 | 243.10 | 92.67 | 7 | 0 |

| UNSPF | PHCF | 3 | 269.13 | 17.17 | 11 | 0 |

| UNSPF | CFM | 3 | 175.93 | 24.20 | 4 | 0 |

| UNSPF | BWXT-NEC | 4 | 247.33 | 525.73 | 10 | 0 |

| UNSPF | SRBT | 2 | 87.37 | 11.83 | 0 | 0 |

| UNSPF | Nordion | 2 | 124.33 | 0.73 | 0 | 0 |

| UNSPF | BTL | 2 | 160.10 | 6.53 | 0 | 0 |

| RRs | Polytechnique Montréal | 2 | 68.30 | 26.90 | 2 | 1 |

| RRs | MNR | 3 | 231.43 | 76.1 | 0 | 0 |

| RRs | RMC | 2 | 85.77 | 21.27 | 2 | 0 |

| RRs | SRC | 2 | 167.43 | 287.73 | 3 | 0 |

Compliance verification

The CNSC ensures licensee compliance through verification, enforcement and reporting activities. CNSC staff implement compliance plans for each site by conducting regulatory activities including inspections, desktop reviews and technical assessments of licensee programs, processes and reports.

Appendix B contains a list of CNSC inspections carried out at UNSPF and RRs for the applicable reporting periods, 2020 and 2018–20 respectively. All findings in these inspections were considered to be of low risk, and did not have an impact on safety at the facilities.

Although some SCAs were not the focus of inspections from 2018–20, CNSC staff performed desktop compliance verification of the various SCAs by reviewing licensees’ compliance reporting submissions (such as annual and quarterly compliance monitoring reports) and specific program documentation.

Licensing

CNSC staff activities for licensing include drafting new or amended licences, preparing CMDs, and drafting or revising licence conditions handbooks (LCHs).

As CNSC regulatory documents are published, CNSC staff update the LCHs as applicable for each site, taking into consideration the licensee’s implementation plans. Appendix C provides a list of changes to uranium and nuclear substance processing facility and RR licences and LCHs. CNSC staff verify the implementation as part of ongoing compliance verification activities. Appendix D provides a list of CNSC regulatory documents implemented at UNSPF and RRs and used by CNSC staff for compliance verification. Appendix E presents the financial guarantee amounts for each facility.

IAEA safeguards activities

Under the terms of the Canada–IAEA safeguards agreements, the IAEA performs verification activities to confirm that all nuclear material in Canada remains in peaceful use. The CNSC regulatory framework requires Canadian operators to provide the access, assistance, and information required for the IAEA to complete its activities. CNSC staff ensure operator compliance with these requirements.

5.2 Performance Ratings for 2020

CNSC staff assign performance ratings to licensees based on the results from regulatory oversight activities.

These ratings are either "satisfactory" (SA) or "below expectations" (BE) for the UNSPF (2020) and RRs (2018–20). The "fully satisfactory" (FS) rating is no longer in use. It is important to recognize that a rating of SA in the current ROR instead of FS used in a previous ROR does not indicate a reduction in performance. In 2020, the Commission agreed with the use of this simplified ratings approach for the RORs [2], which is consistent with the CNSC’s effort to implement neutral, fair regulatory oversight. This revised system has allowed CNSC staff to focus on facilities’ performance.

For 2020, CNSC staff rated the performance in each SCA as "satisfactory" (SA) for all UNSPF and RRs. Appendix F provides SCA ratings for each licensee from 2016 to 2020.

6 The CNSC’s assessment of safety at uranium and nuclear substance processing facilities and research reactors

The CNSC regulates all aspects of safety at nuclear sites in Canada, including risks to workers, the public and the environment. All 14 SCAs, discussed in the following paragraphs, are assessed. Detailed information is provided on radiation protection, conventional health and safety, and environmental protection, since these 3 SCAs are considered the most indicative of safety performance at the UNSFP and RRs. In particular, the SCAs of radiation protection and conventional health and safety are a good measure of the safety of workers, while the SCA of environmental protection is an appropriate measure with respect to the safety of people and the environment.

6.1 Management System

The management system SCA covers the framework that establishes the processes and programs required to ensure that an organization achieves its safety objectives, continuously monitors its performance against these objectives, and fosters a healthy safety culture.

CNSC staff assess performance in the management system SCA by verifying compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. The specific areas assessed within the management system include organization, planning and controlling business activities, resource management, communication, safety culture, change management, information management, work management, problem identification and resolution, performance assessment, improvement, and management review.

NNCs from inspections related to the management system SCA were issued for the following licensees over the reporting period:

- 1 NNC at Nordion, based on implementation measures to ensure records are complete and traceable in accordance with CSA standard N286-12, Management Systems for Nuclear Facilities [3]

- 2 NNCs at BTL, based on the accessibility of records related to facility maintenance and their approved supplier list

- 1 NNC at Polytechnique Montréal in 2020, relating to the timely implementation of corrective actions

The licensees have taken all necessary corrective actions to address the above noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility.

CNSC staff concluded that the UNSPF and RRs met regulatory requirements and maintained and implemented satisfactory management system programs for the applicable reportable years. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.2 Human Performance Management

The human performance management SCA covers activities that enable effective human performance through the development and implementation of processes that ensure a sufficient number of licensee personnel are in all relevant job areas and have the necessary knowledge, skills, procedures and tools in place to safely carry on their duties.

CNSC staff assess performance in the human performance management SCA by verifying compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. For this SCA, CNSC staff verify that licensees are in compliance with REGDOC-2.2.2, Personnel Training [4], and their documented personnel training programs.

NNCs from inspections related to the human performance management SCA were issued for the following licensees over the reporting period:

- 1 NNC at BRR, on the documentation related to the systematic approach to training (SAT) implemented onsite

- 3 NNCs at SRBT, based on findings related to the SAT-based personnel training program

- 4 NNCs at BTL, related to training requirements for SAT-based positions

- 1 NNC at MNR, related to the training and qualification plan for the MNR Emergency Organization in 2018

- 3 NNCs at the MNR, related to program documentation in 2020, which was assessed for the first time against the requirements of REGDOC-2.2.2, Personnel Training [4]

The licensees have taken all necessary corrective actions to address the above noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility.

CNSC staff concluded that the UNSPF and RRs implemented and maintained effective programs specific to personnel training and met regulatory requirements. CNSC staff will continue to verify that licensees are in compliance with the requirements for their programs and procedures, as part of ongoing regulatory oversight activities.

6.3 Operating Performance

The operating performance SCA includes an overall review of the conduct of the licensed activities and the activities that enable effective performance.

CNSC staff assess performance in the operating performance SCA by verifying that policies, programs, methods and procedures are in place for the safe operation and maintenance of nuclear facilities. Verification of compliance with the requirements of this SCA are included as part of CNSC’s compliance verification activities ranging from desktop reviews of annual reports, reviews of event reports, related corrective actions, and planned or reactive inspections.

NNC from inspections related to the operating performance SCA were issued for the following licensee over the reporting period:

- 1 NNC at Nordion, based on implementation measures to ensure that events are reported to the CNSC in accordance with REGDOC-3.1.2, Reporting Requirements for Non-Power Reactor Class I Nuclear Facilities and Uranium Mines and Mills [5]

The licensee has taken all necessary corrective actions to address the above noted NNC. The finding was of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility.

CNSC staff concluded, through compliance verification activities, that UNSPF and RRs implemented and maintained effective operating programs in order to ensure that licensed activities are conducted safely and in compliance with regulatory requirements. CNSC staff will continue to monitor licensee performance through regulatory oversight activities pertaining to this SCA.

6.4 Safety analysis

The safety analysis SCA covers the maintenance of the safety analysis that supports the overall safety case for the facility. Safety analysis is a systematic evaluation of the potential hazards associated with the conduct of a proposed activity or facility and considers the effectiveness of preventative measures and strategies in reducing the effects of such hazards.

CNSC staff assess performance in the safety analysis SCA by verifying compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff verify that licensees maintain safety analysis reports (SARs) to include updated information on the description of the facility and the measures in place to protect the safety of the workers, the public and the environment, under normal operations, abnormal operations and accident conditions. CNSC staff asses the SARs to ensure they provide an assessment of the potential consequences and demonstrate the safety case through defence in depth.

For inspections related to the safety analysis SCA over the reporting period, all licensees were found to be compliant. CNSC staff concluded that the UNSPF and RRs met regulatory requirements and maintained satisfactory ratings in the safety analysis SCA for the applicable reportable years. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.5 Physical design

The physical design SCA relates to activities that impact the ability of structures, systems and components to meet and maintain their design basis given new information arising over time and taking changes in the external environment into account.

CNSC staff assess performance in the physical design SCA by verifying compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff verify the physical design SCA requirements by ensuring the implementation of national codes and standards for structural design and maintaining authorized inspection agency formal agreements including pressure-retaining programs where applicable.

NNCs from inspections related to the physical design SCA were issued for the following licensee over the reporting period:

- 2 NNCs at the PHCF, related to updating and implementing documentation for the pressure boundary program

The licensee has taken all necessary corrective actions to address the above noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility.

CNSC staff concluded that the UNSPF and RRs met regulatory requirements and maintained satisfactory ratings in the physical design SCA for the applicable reportable years. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.6 Fitness for service

The fitness for service SCA covers activities that impact the physical condition of structures, systems and components to ensure that they remain effective over time. This area includes programs that verify all equipment is available to perform its intended design function when called upon to do so.

CNSC staff assess performance in the fitness for service SCA by verifying compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff verify that the programs cover activities that affect the physical condition of structures, systems and components over time. Specific areas are assessed within this SCA to ensure that the fitness for service programs are supported by detailed procedures on preventative maintenance, measuring and testing of equipment and new equipment validation.

NNC from inspections related to the fitness for service SCA were issued for the following licensee over the reporting period:

- 1 NNC at CFM, related to the completion of scheduled gauge verifications

The licensee has taken all necessary corrective actions to address the above-noted NNC. The finding was of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility.

CNSC staff concluded that the UNSPF and RRs met regulatory requirements and maintained satisfactory ratings in the fitness for service SCA for the applicable reportable years. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.7 Environmental protection

Protection of the environment and the public are linked in the SCA of environmental protection. This SCA covers programs that identify, control and monitor all releases of radioactive and hazardous substances, and the effects on the environment from facilities or as a result of licensed activities.

NNCs from inspections related to the environmental protection SCA were issued for the following licensees over the reporting period:

- 1 NNC at PHCF, related to conducting documented visual inspections of the cooling water intake operating system and related fish barriers to ensure that existing mitigation measures remain effective at reducing and/or preventing fish impingement and entrainment

- 1 NNC at CFM, based on a finding related to fenceline gamma monitoring.

The licensees have taken all necessary corrective actions to address the above noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility

Currently, all licensees covered by this ROR have acceptable environmental protection programs in place to ensure the protection of the public and the environment. CNSC staff rated the environmental protection SCA at all UNSPF and RRs as "satisfactory".

Appendix G provides the total annual releases of radionuclides for the UNSPF and RRs from 2016 to 2020. Appendix H contains data on dose to the public from 2016 to 2020. Appendix I contains supplemental environmental data for all licensees.

Effluent and emissions control (releases)

All UNSPF and RRs implement effluent monitoring programs commensurate with the risks of their operations. Airborne and waterborne releases of radioactive and hazardous substances at UNSPF and RRs remained below regulatory limits in 2020.

Action levels

Action levels are a tool used to ensure that licensees are operating their facility appropriately and in accordance with their approved program(s) and within the design and operational parameters of their wastewater treatment and air pollution control systems.

Action levels serve as an early warning system to ensure that licensees are carefully monitoring their operation and performance, to ensure release limits are not exceeded. Action level exceedances are reportable to the CNSC.

Each licensee is responsible for identifying the parameters of its own program(s) to represent timely indicators of potential losses of control of the program(s). These licensee-specific action levels may also change over time, depending on operational and radiological conditions.

If an action level is reached, it triggers the licensee to determine the cause, notify the CNSC and, if applicable, take corrective action to restore the effectiveness of the environmental protection program. It is important to note that occasional action level exceedances indicate that the action level chosen is likely an adequately sensitive indicator of a potential loss of control of the program.

Licensee performance is not evaluated solely on the number of action level exceedances in a given period, but also on how the licensee responds and implements corrective actions to enhance program performance and prevent reoccurrence. Licensees are required to periodically review their action levels to validate their effectiveness.

The following environmental action level exceedances were reported to the CNSC:

- On March 13, 2020, 1 action level exceedance occurred at the PHCF, where the uranium concentration (160 μg U/L) exceeded the sanitary sewer discharge action level (100 μg U/L). This occurrence was due to groundwater infiltration from a heavy precipitation event. Cameco has implemented corrective actions and are continuing to repair and upgrade sections of the sanitary sewer network as part of the VIM project.

- On July 13, 2020, a burnout of a fluorine inlet valve resulted in an elevated fluoride emission of 273 grams/hr which exceeded the action level of 230 g/hr. Cameco’s uranium hexafluoride plant was shut down immediately. The fluorine inlet valve was replaced and the plant was restarted the following day.

- On April 30 and May 31, 2020, the fenceline gamma action level at station 31 was exceeded on 2 occasions. The April and May gamma radiation measurements were 0.28 and 0.26 uSv/hr respectively, which exceeded the action level of 0.22 uSv/hr. Cameco’s investigation determined that the exceedances were due to uranium hexafluoride cylinder storage in the area. Cameco reviewed and adjusted the cylinder storage in the area to reduce exposures.

- On March 17, 2021, BWXT-NEC Toronto reported that they had been applying the release limits for pH (6.0–9.5) set by the City of Toronto sewer use bylaw which is less restrictive than their CNSC-accepted action levels for liquid effluent (6.65–9.0). As a result, there were 27 instances of exceedances of the lower pH action level. The exceedances were in the range of 6.01–6.63, with 26 exceedances occurring in 2020 and 1 exceedance in 2019.

None of the releases exceeded the City of Toronto sewer use bylaw (6.0–9.5) requirements and there were no potential environmental impacts associated with these exceedances. An investigation was completed and corrective actions were identified. CNSC staff are in the process of reviewing the corrective actions submitted by the licensee.

CNSC staff have assessed that there was no impact to workers, the public or the environment as a result of these action level exceedances. CNSC staff reviewed the licensees’ corrective actions in relation to the exceedances and are satisfied with the licensee’s responses.

Environmental management system

The CNSC requires each licensee to develop and maintain an environmental management systems (EMS) that provide a framework for integrated activities related to environmental protection. EMS are described in environmental management programs and include activities such as the establishment of annual environmental objectives, goals and targets. Licensees conduct internal audits of their programs at least once a year. As part of regular compliance verification, CNSC staff review and assess these objectives, goals and targets. CNSC staff determined that the UNSPF and RRs established and implemented their EMS in compliance with CNSC regulatory requirements.

Assessment and monitoring

CNSC staff verify that UNSPF and RRs have environmental monitoring programs commensurate with the risks of the operations at each of their facilities. The environmental monitoring programs are designed to monitor releases of radioactive and hazardous substances, and to characterize the quality of the environment associated with the licensed facility. CNSC staff determined that the UNSPF and RRs established and implemented environmental monitoring programs in compliance with CNSC regulatory requirements where applicable.

Environmental risk assessment

Licensees develop environmental risk assessments (ERAs) to analyze the risks associated with contaminants in the environment as a result of licensed activities. ERAs provide the basis for the scope and complexity of environmental monitoring programs at the UNSPF and RRs.

ERAs for UNSPF

CNSC staff use CSA standard N288.6-12, Environmental Risk Assessments at Class I Nuclear Facilities and Uranium Mines and Mills [6], to help determine whether licensees are in compliance with regulatory requirements for protection of the environment and human health. CSA N288.6-12 specifically states: "Facility ERAs should be reviewed on a 5-year cycle or more frequently if major facility changes are proposed that would trigger a predictive assessment". CNSC staff expect licensees to periodically review ERAs for their facilities, as appropriate. BRR, CFM, and SRBT submitted revised ERAs in 2020 that were in compliance with CSA N288.6-12 [6].

ERAs for RRs

As part of the 2013 licence renewal of the SLOWPOKE-2 facilities, CNSC staff completed a sector specific environmental risk assessment to determine potential impacts to human health and the environment as a result of the operations of the SLOWPOKE-2 facilities. In CNSC staff's assessment, the maximum dose to members of the public that was estimated under normal operations was 0.08 μSv/year. This is several orders of magnitude below the regulatory public dose limit of 1 mSv/yr (1000 μSv/year). In addition, CNSC staff assessed the dose rates to non-human ecological receptors, and the results were orders of magnitude lower than conservative benchmarks. For the MNR, a conservative evaluation of the dose to the public through airborne releases results in less than 1 μSv/year, which is less than 1/1000 of the regulatory dose limit of 1 mSv for a member of the public. In light of these results, no impacts to human health and the environment are expected from the normal operation of RR facilities in Canada.

Protection of people

The CNSC requires licensees to demonstrate that the health and safety of the public are protected from exposures to hazardous (non-radiological) substances released from their facilities. Licensees use effluent and environmental monitoring programs to verify that releases of hazardous substances do not result in environmental concentrations that may affect public health. CNSC staff receive reports of discharges to the environment in accordance with reporting requirements outlined in the licence and the LCH. Based on assessments of the programs at the uranium and nuclear substance processing facilities, CNSC staff concluded that the public continues to be protected from facility emissions of hazardous substances.

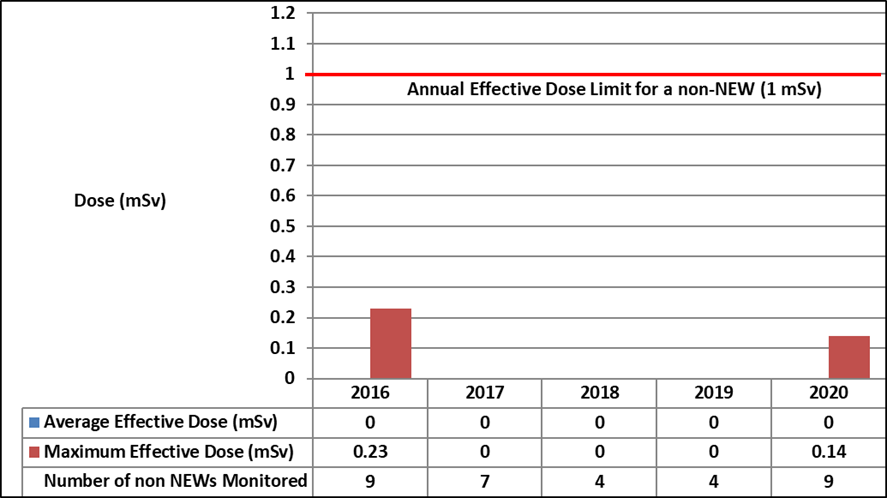

Estimated dose to the public

The maximum dose to the public from licensed activities is calculated by considering monitoring results from air emissions, liquid effluent releases and gamma radiation. The CNSC requires licensees to monitor their facilities and keep doses to the public below the annual public dose limit of 1 mSv/year prescribed in the Radiation Protection Regulations [8]. This requirement is in line with the principle that licensees must keep doses as low as reasonably achievable (ALARA), taking into account social and economic factors.

Table H-1 of Appendix H compares estimated public doses from 2016 to 2020 for the UNSPF and RRs. Estimated doses to the public from all these facilities continued to be well below the regulatory annual public dose limit of 1 mSv/year.

Conclusion on environmental protection

CNSC staff concluded that the UNSPF and RRs implemented their environmental protection programs satisfactorily for the applicable reportable years. The licensees’ programs are effective in protecting the health and safety of people and the environment. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.8 Radiation protection

The radiation protection SCA covers the implementation of a radiation protection program in accordance with the Radiation Protection Regulations [8]. The program must ensure that contamination levels and radiation doses received by individuals are monitored, controlled and maintained ALARA.

NNCs from inspections related to the radiation protection SCA were issued for the following licensees over the reporting period:

- 1 NNC at BRR related to the implementation of measures to ensure employees, contractors, and visitors adhere to whole body monitoring protocols

- 2 NNCs at CFM based on findings related to radiation warning signage

The licensees have taken all necessary corrective actions to address the above noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility. CNSC staff rated the radiation protection SCA at all UNSPF and RRs as "satisfactory".

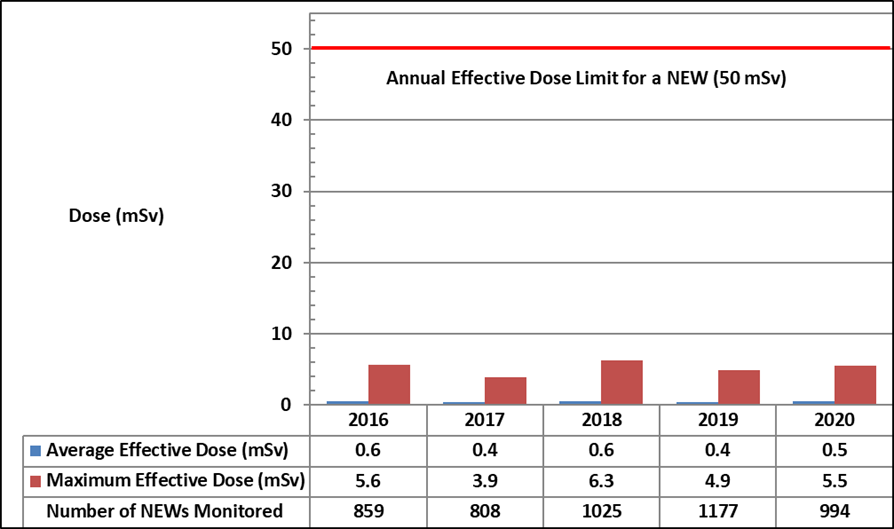

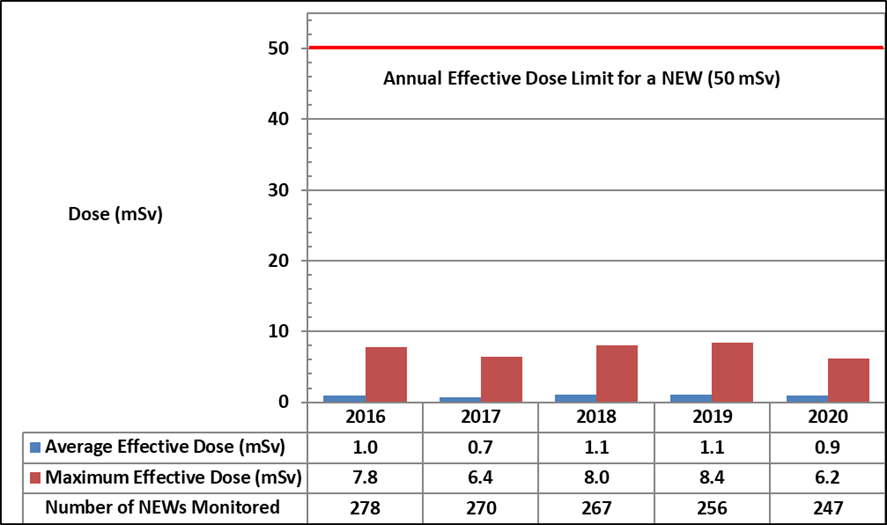

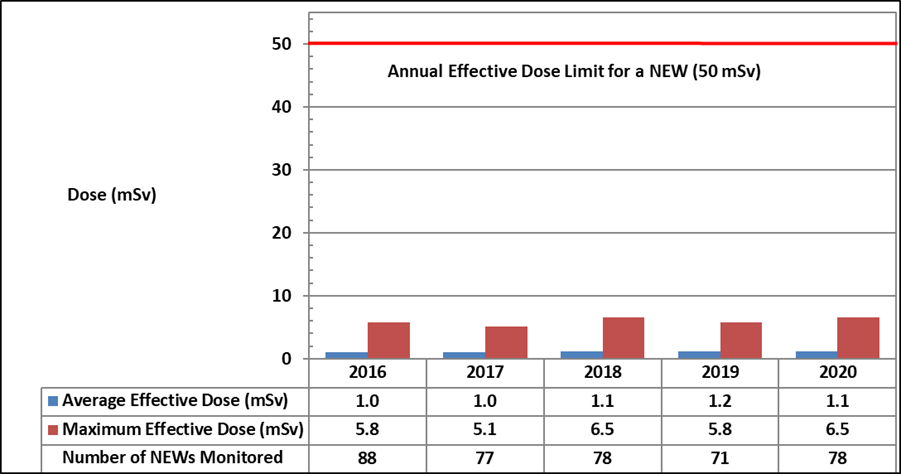

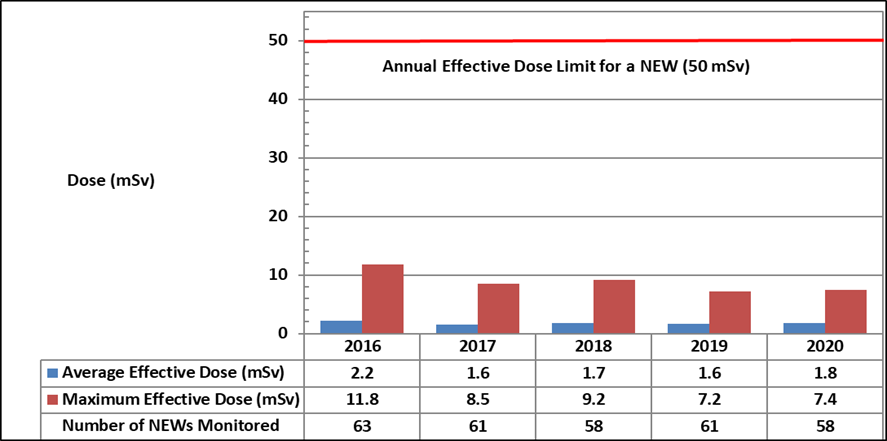

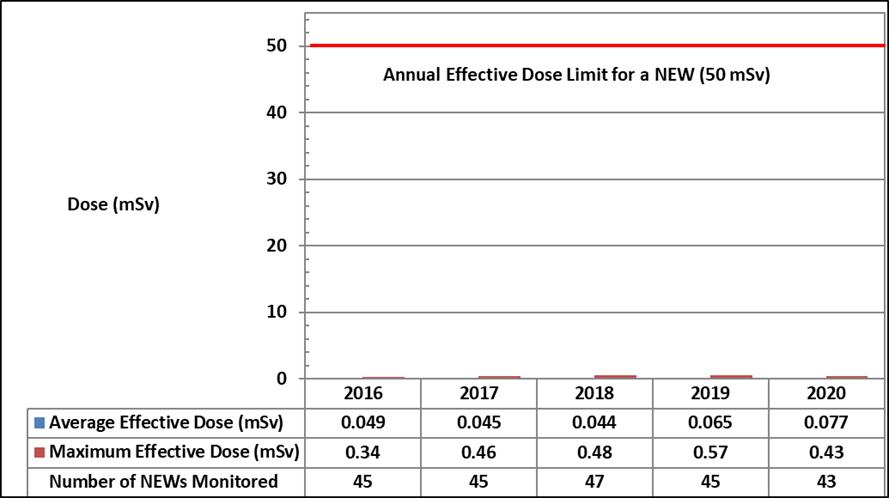

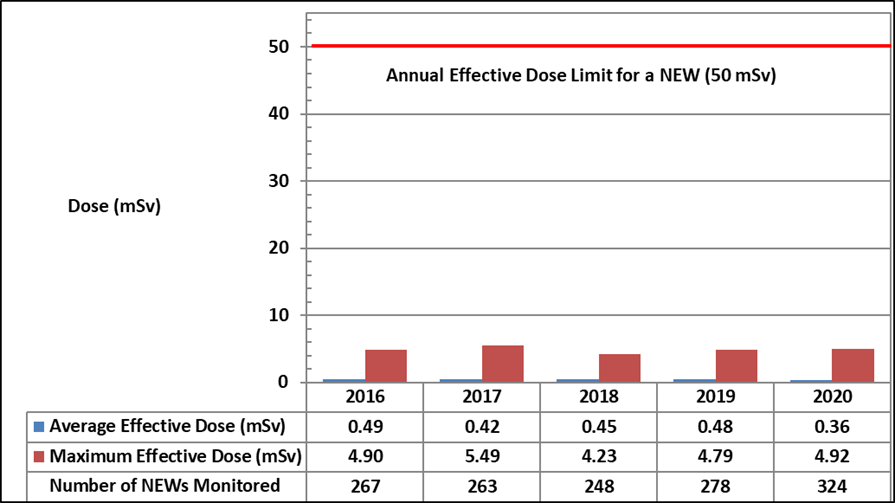

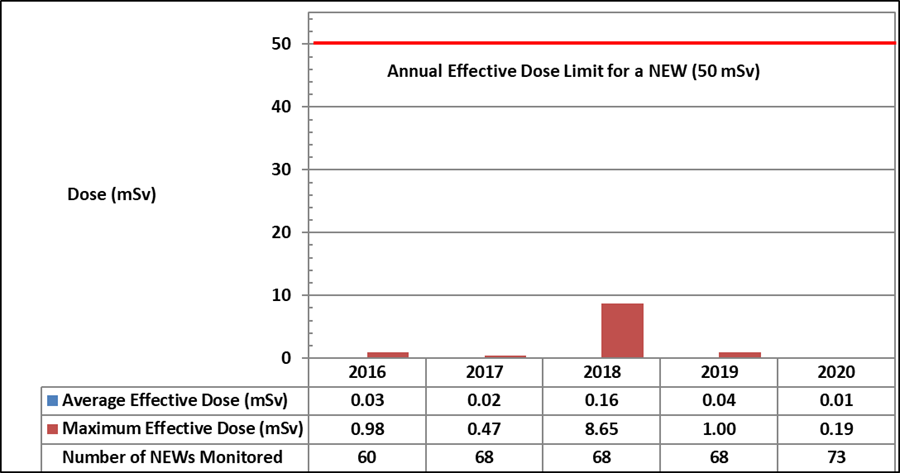

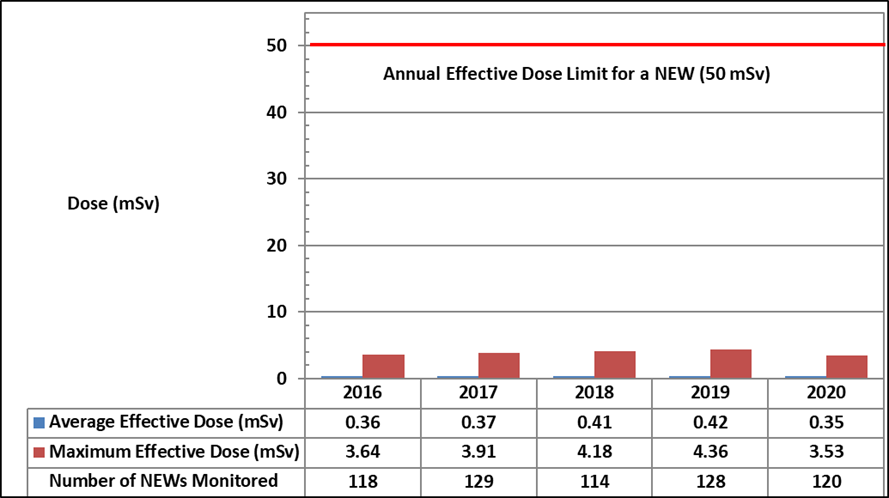

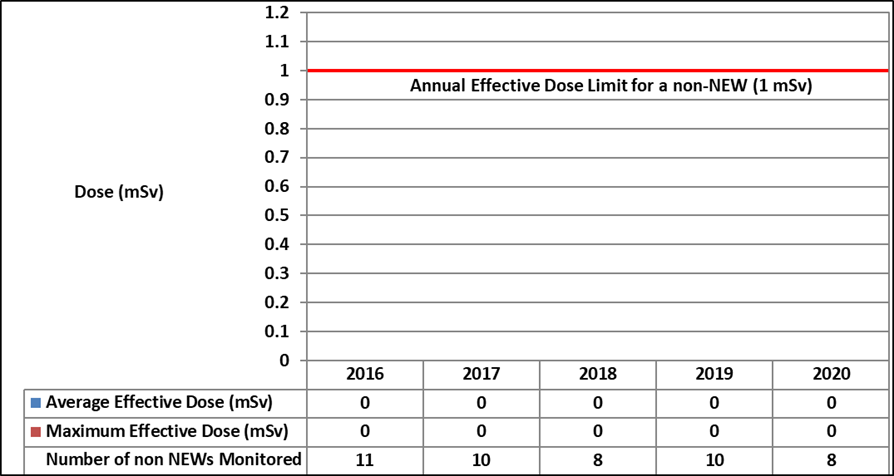

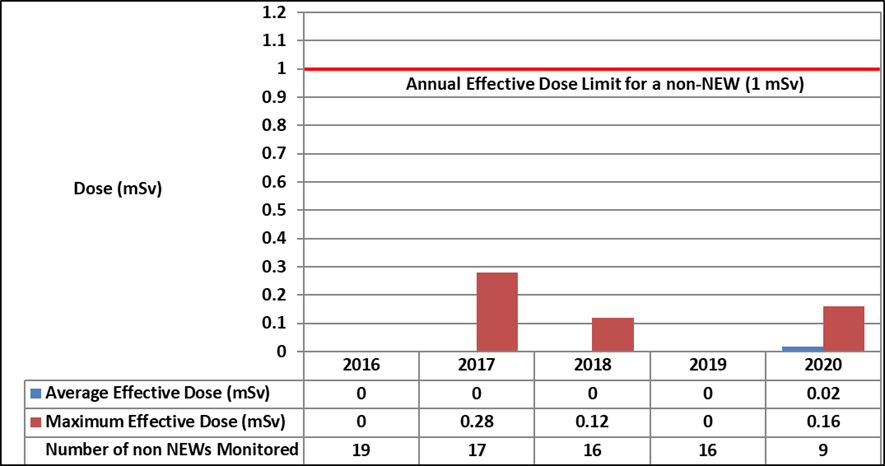

Appendix J contains data on dose to workers for the UNSPF and RRs from 2016 to 2020.

Application of ALARA

CNSC staff confirmed that all UNSPF and RRs continued to implement radiation protection measures to keep radiation exposures and doses to persons ALARA. The CNSC requirement for licensees to apply the ALARA principle has consistently resulted in these doses staying well below regulatory dose limits.

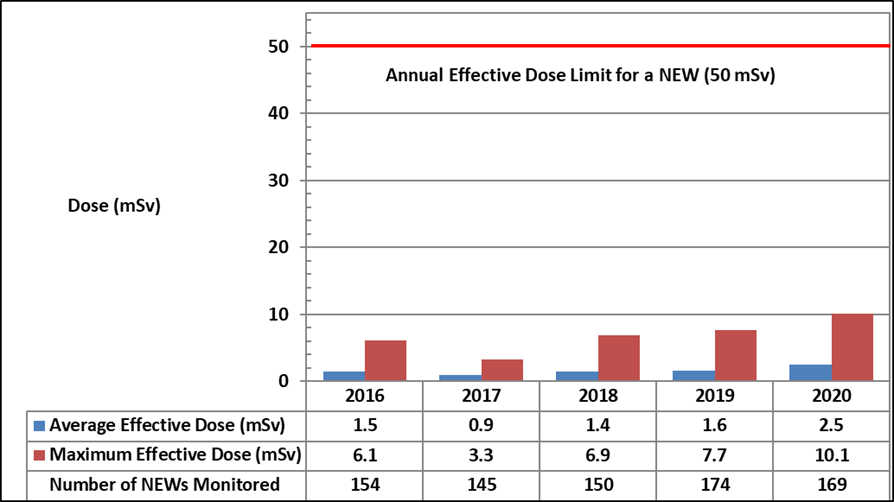

Worker dose control

The design of radiation protection programs includes the dosimetry methods and the determination of workers who are identified as nuclear energy workers (NEWs). These designs vary, depending on the radiological hazards present and the expected magnitude of doses received by workers. The dose statistics provided in this report are primarily for NEWs, with the inherent differences in the design of radiation protection programs among licensees taken into consideration. Additional information on the total number of monitored persons, including workers, contractors and visitors, is provided in Appendix J. CNSC staff confirmed that all UNSPF and RRs monitored and controlled the radiation exposures and doses received by all persons present at their licensed facilities, including workers, contractors and visitors. Direct comparison of doses received by NEWs among facilities does not necessarily provide an appropriate measure of a licensee’s effectiveness in implementing its radiation protection program, since radiological hazards differ across these facilities due to complex and varying work environments.

Radiation protection program performance

CNSC staff conducted regulatory oversight activities at UNSPF and RRs to verify that the licensees’ radiation protection programs complied with regulatory requirements. These oversight activities included inspections, desktop reviews, and compliance verification activities specific to radiation protection. Through these activities, CNSC staff confirmed that all these licensees have effectively implemented their radiation protection programs, to control occupational exposures to workers and keep doses ALARA.

Action levels

The following radiation protection action level exceedance was reported to the CNSC:

- In July 2020 at BRR, a worker’s dosimeter recorded a skin dose of 26.4 mSv, which exceeded Cameco’s monthly skin dose action level of 15 mSv. Cameco’s investigation determined that the dose was mostly non-personal, as the dosimeter was lost for a period of time in a processing area. A dose change request was pursued by Cameco and approved by the CNSC. CNSC staff are satisfied with Cameco’s responses to the action level exceedance.

Radiological hazard control

CNSC staff verified that UNSPF and RRs continued to implement adequate measures to monitor and control radiological hazards in their facilities. These measures included delineation of zones for contamination control purposes and in-plant air-monitoring systems. Licensees demonstrated that they have implemented workplace monitoring programs to protect workers. The licensees have also demonstrated that levels of radioactive contamination were controlled within their facilities throughout the year.

Conclusion on radiation protection

CNSC staff concluded that the UNSPF and RRs effectively implemented and maintained their radiation protection programs for the applicable reportable years. The licensees’ programs are effective in ensuring the health and safety of persons working in their facilities. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.9 Conventional health and safety

The conventional health and safety SCA covers the implementation of a program to manage workplace safety hazards and to protect workers.

Based on regulatory oversight activities, CNSC staff rated the performance of all UNSPF (2020) and RRs (2018–20) for the conventional health and safety SCA as "satisfactory".

Appendix K contains health and safety information for each UNSPF and RR from 2016 to 2020.

Performance

Employment and Social Development Canada (ESDC) and the CNSC regulate conventional health and safety programs at UNSPF and RRs. Licensees submit hazardous-occurrence investigation reports to both ESDC and the CNSC, in accordance with their respective reporting requirements. CNSC staff monitor compliance with regulatory reporting requirements and, when a concern is identified, consult with ESDC staff.

Licensees are required to report to the CNSC as directed by section 29 of the General Nuclear Safety and Control Regulations [9]. These reports include serious illnesses or injuries incurred or possibly incurred as a result of a licensed activity.

A key performance measure for the conventional health and safety SCA is the number of lost-time injuries (LTIs) that occur per year. An LTI is an injury that takes place at work and results in the worker being unable to return to work to carry out their duties for a period of time. There were no LTIs at the UNSPF in 2020 or the RRs from 2018–20.

Practices

Licensees are responsible for developing and implementing conventional health and safety programs for the protection of their workers. These programs must comply with Part II of the Canada Labour Code [10].

CNSC staff conducted desktop reviews and inspections at all UNSPF (2020) and RRs (2018–20) to verify compliance of the licensees’ conventional health and safety programs with regulatory requirements.

NNCs from inspections related to the conventional health and safety SCA were issued for the following licensees over the reporting period:

- 1 NNC at PHCF, related to ensuring that employees are alerted when mandatory training is missed, and that measures are taken to reduce or eliminate non-conformance with training requirements

- 3 NNCs at CFM, related to non-radiological workplace hazard signage, personnel roles and responsibilities documentation, and legibility of lockout tags used for the control of hazardous energy

The licensees have taken all necessary corrective actions to address the above-noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility.

CNSC staff concluded, based on regulatory oversight activities, that the UNSPF and RRs met all regulatory requirements for this specific area.

Awareness

Licensees are responsible for ensuring that workers have the knowledge to identify workplace hazards and take the necessary precautions to protect against these hazards. This is accomplished through training and ongoing internal communications with workers.

During inspections, CNSC staff verify that workers are trained to identify hazards at the facilities. CNSC staff confirmed that UNSPF and RRs have effectively implemented their conventional health and safety programs to keep workers safe.

Conclusion on conventional health and safety

CNSC staff concluded that the UNSPF and RRs implemented their conventional health and safety programs satisfactorily for the applicable reportable years. The programs are effective in protecting the health and safety of persons working in these facilities. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.10 Emergency management and fire protection

The emergency management and fire protection SCA covers emergency plans and emergency preparedness programs that exist for emergencies and for non-routine conditions.

CNSC staff assess performance in the emergency management and fire protection SCA by verifying compliance of licensee documents and programs with requirements. This is done through desktop reviews as well as compliance verification inspections that are planned or reactive. Specific areas assessed within this SCA include how licensees respond to conventional and nuclear events, both onsite and offsite, and events that can affect the facility. CNSC staff ensure that comprehensive fire protection programs are also in place to minimize the risk to the health and safety of persons and to the environment from fire, through appropriate fire protection system design, fire safety analysis, fire safe operation and fire prevention.

NNCs from inspections related to the Emergency Management and Fire Protection SCA were issued for the following licensees over the reporting period:

- 1 NNC at the PHCF, related to the placement of an emergency exit sign

- 2 NNCs at the MNR in 2018, regarding documentation of the emergency management program

The licensees have taken all necessary corrective actions to address the above noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility.

CNSC staff concluded that the UNSPF and RRs met regulatory requirements and maintained satisfactory ratings in the emergency management and fire protection SCA for the applicable reportable years. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.11 Waste management

The waste management SCA covers internal waste-related programs that form part of the facility’s operations up to the point where the waste is removed from the facility to a separate waste management facility. This SCA also covers the planning for decommissioning.

CNSC staff assess performance in the waste management SCA by verifying compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff ensure that the licensees properly manage wastes throughout the lifecycle of a nuclear facility, which includes the maintenance of an up-to-date waste inventory and waste tracking. The CNSC requires that licensees have a decommissioning plan and financial guarantee to ensure that the health, safety, and security of workers, the public, and the environment remains protected.

NNCs from inspections related to the waste management SCA were issued for the following licensees over the reporting period:

- 1 NNC at Nordion related to waste inventory record keeping

- 1 NNC at SRC during the 2020 decommissioning inspection to provide characterization reports of the waste to the CNSC

The licensees have taken all necessary corrective actions to address the above noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people or the environment, or the safe operation of the facilities.

CNSC staff concluded that the UNSPF and RRs met regulatory requirements, and maintained and implemented satisfactory waste management programs for the applicable reportable years. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.12 Security

The security SCA covers the programs required to implement and support the security requirements stipulated in the regulations, the licence, orders, or expectations for the facility or activity.

CNSC staff assess performance in the security SCA by verifying compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. Specific areas assessed within this SCA include programs and procedures relating to access control, response arrangements, security practices, cyber security and drills and exercises. CNSC staff ensure that the security programs in place prevent the loss, unauthorized removal and sabotage of nuclear substances, nuclear materials, prescribed equipment and information.

Security inspections and details of security arrangements with the licensees are confidential. NNCs from inspections related to the security SCA were issued for the following licensees over the reporting period:

- 2 NNCs at PHCF

- 2 NNCs at CFM

- 1 NNC at BWXT-NEC Peterborough

- 3 NNCs at Polytechnique Montréal in 2019

- 2 NNCs at RMC in 2019

The licensees have taken corrective actions to address the above noted NNCs, and most have been addressed. Remaining items are scheduled for completion in 2021, subject to limitations associated with the COVID-19 pandemic. The findings were of low safety significance and did not affect the health and safety of workers, people and the environment, or the safe operation of the facility.

CNSC staff concluded that the UNSPF and RRs met regulatory requirements and maintained and implemented satisfactory security programs for the applicable reportable years. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.13 Safeguards and non-proliferation

The safeguards and non-proliferation SCA covers the programs and activities required for the successful implementation of the obligations arising from the Canada/IAEA safeguards agreements, as well as all other measures arising from the Treaty on the Non-Proliferation of Nuclear Weapons (NPT).

CNSC staff assess performance in the safeguards and non-proliferation SCA by verifying licensee compliance through desktop reviews and in-field activities, including participation in IAEA verification activities. CNSC staff verify that licensees meet Canada’s international safeguards obligations as well as other measures arising from the NPT. CNSC staff ensure that the licensees have implemented and maintained effective programs to allow the implementation of both safeguards measures and non-proliferation commitments.

NNCs from inspections and safeguards verification activities related to the safeguards and non-proliferation SCA were issued for the following licensees over the reporting period:

- 1 NNC at BWXT-NEC (Toronto & Peterborough) related to not using the Canadian obligation code on the inventory change document

- 2 NNCs at BRR related to its accountability scale where Cameco was requested to assess its calibration and maintenance practices, including the use of standard weights for calibration, and implement clear position markings for the placement of tote bins

- 1 NNC at PHCF requesting that actions be taken to ensure that calibration requirements are consistently being met at the UF4 drumming station

The licensees have taken the necessary actions to address the above noted NNCs. The findings did not affect the health and safety of workers, the public, or the environment, or the safe operation of the facility. CNSC staff continue to monitor the facilities compliance to the REGDOC-2.13.1, Safeguards and Nuclear Material Accountancy [11], including the implementation of scale calibration procedures.

The licensees require a licence, separate from the licensing of their operations, for the import and export of controlled nuclear substances, equipment and information identified in the Nuclear Non-proliferation Import and Export Control Regulations [12].

CNSC staff concluded that the UNSPFFootnote 2 and RRs met regulatory requirements and maintained and implemented satisfactory safeguards and non-proliferation programs for the applicable reportable years. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.14 Packaging and transport

The packaging and transport SCA covers the safe packaging and transport of nuclear substances to and from the licensed facilities. CNSC staff assess performance in the packaging and transport SCA by verifying compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff ensure that all elements of package design, package maintenance, and the registration for use of certified packages are in compliance with the Packaging and Transport of Nuclear Substances Regulations, 2015 [13] and Transportation of Dangerous Goods Regulations [14].

There were no NNCs from inspections related to the packaging and transport SCA for the licensees covered in this report, over the reporting periods. CNSC staff concluded that the UNSPF and RRs met regulatory requirements and maintained satisfactory ratings in the packaging and transport SCA for the applicable reportable years. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

7 The CNSC’s assessment of safety at uranium and nuclear substance processing facilities and research reactors

7.1 Reportable events